Volume 8

Journal of Biotechnology and Biomaterials

ISSN: 2155-952X

Biomaterials 2018

March 05-06, 2018

Page 74

conference

series

.com

March 05-06, 2018 | Berlin, Germany

3

rd

Annual Conference and Expo on

Biomaterials

Bernhard Mingler, J Biotechnol Biomater 2018, Volume 8

DOI: 10.4172/2155-952X-C1-087

Biomaterials with unique properties for implant applications

E

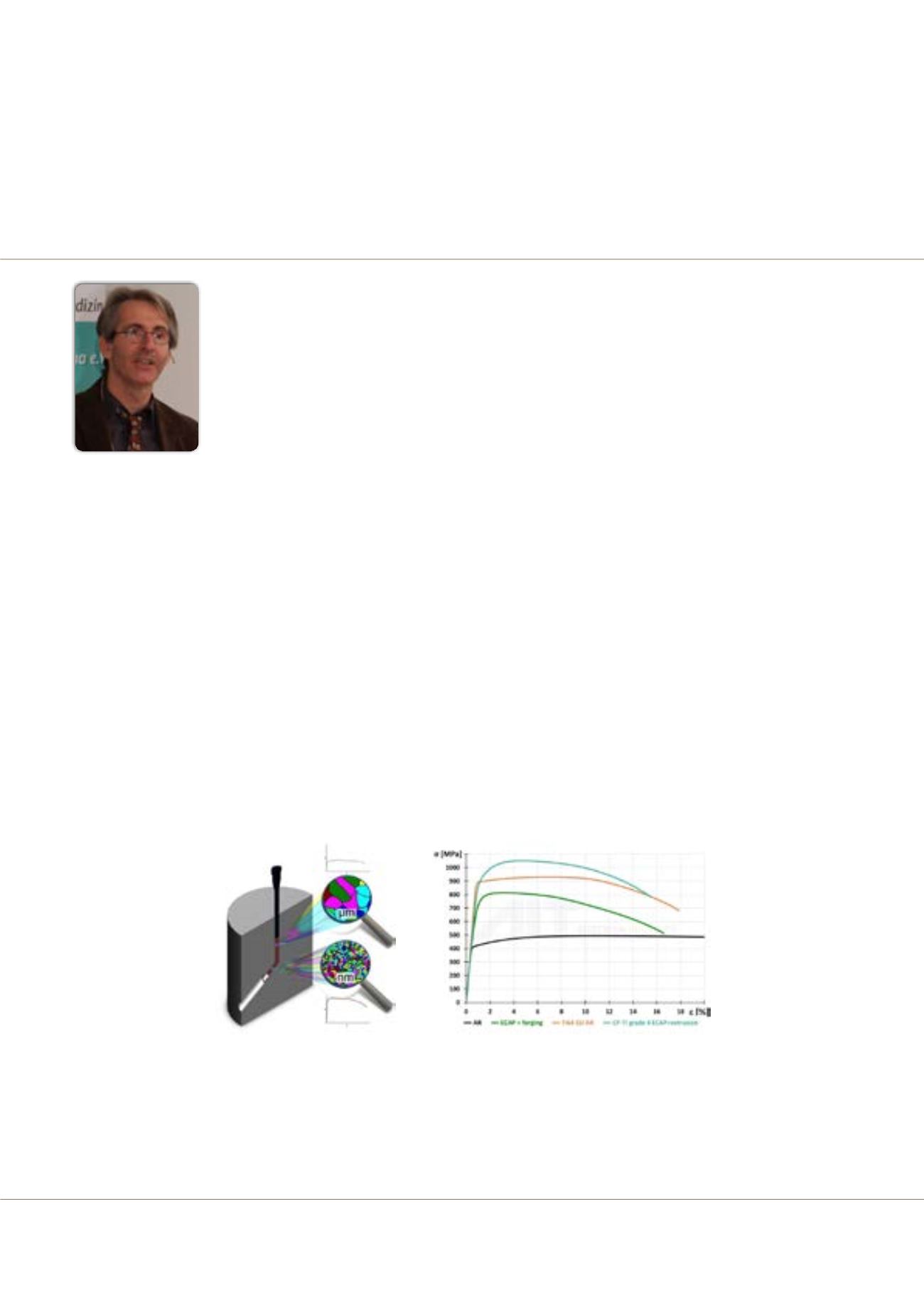

qual Channel Angular Pressing (ECAP) is an innovative processing technology for the production of metallic biomaterials

with unique properties. It leads to a strong grain refinement of bulk crystalline materials down to the sub-micrometer range by

means of very large, multidimensional plastic deformation under enhanced hydrostatic pressure. The modified microstructure of

ECAP-processed biomaterials is the reason for high strength combined with good ductility. Such high-performance biomaterials

are very promising candidates for applications in high-loaded implants, for longer implant lifespans, for the miniaturization of

implants and for completely new implant concepts. The effects of ECAP are presented on the examples of commercially pure (CP)-

titanium and special Mg-alloys. CP-Ti is a commonly used implant material especially in dentistry. In this field of application,

the Ti-alloy Ti6Al4V-ELI is avoided because of its problematic alloying elements aluminum and vanadium. Nevertheless, for

many dental applications a higher strength than that of CP-Ti is requested. Using ECAP and tailored optional post-processing we

achieved in CP-Ti ultimate tensile strengths >1000 MPa, which is stronger than the Ti-alloy. A further very important effect of

ECAP is that it produces a very homogeneous ultrafine grain structure and consequently very homogeneous mechanical property

across the whole work piece. The ideal material for biodegradable implants must combine high biocompatibility, application-

oriented degradation rate and excellent mechanical properties especially for load bearing applications. To achieve all these goals,

we used a newly developed double-ECAP tool to process a special low alloyedMg alloy which was developed and produced at AIT.

The double-ECAP tool consists of three channels with two intersection angles and offers exceptional high deformation efficiency.

By using it, the ultimate tensile strength of a ZX00 Mg alloy could be raised to unprecedented strength values of about 400 MPa.

Figure 1: Principle of Equal Channel Angular Pressing ECAP (left); stress strain curves of CP-Ti in different conditions in comparison with

Ti6Al4V- ELI. CP-Ti grade 4 after ECAP + extrusion is stronger than the Ti alloy

Recent publications

Bernhard Mingler

Austrian Institute of Technology GmbH, Austria