Volume 8

Journal of Biotechnology and Biomaterials

ISSN: 2155-952X

Biomaterials 2018

March 05-06, 2018

Page 76

conference

series

.com

March 05-06, 2018 | Berlin, Germany

3

rd

Annual Conference and Expo on

Biomaterials

Kunio Ishikawa, J Biotechnol Biomater 2018, Volume 8

DOI: 10.4172/2155-952X-C1-087

Carbonate apatite: Next generation artificial bone replacement

A

lthough bone apatite is the carbonate apatite (CO

3

Ap) that contains 6-9 wt% carbonate in apatitic structure, hydroxyapatite

(HAp) has been used as one of typical artificial bone substitute since CO

3

Ap powder start to decompose at 400°C, thus

cannot be sintered. We have found that CO

3

Ap block can be fabricated by compositional transformation though a dissolution–

precipitation reaction using precursors such as calcium carbonate and tricalcium phosphate. Although HAp is not resorbed by

osteoblasts, CO

3

Ap thus fabricated was resorbed by osteoclasts similar to bone. As a result of osteoclastic resorption, CO

3

Ap is

replaced by bone whereas HAp remained as it is at the bone defects. CO

3

Ap up-regulate differentiation of osteoblasts even when

compared to HAp. Figure 3 show the typical Villanueva Goldner staining of HAp and CO

3

Ap when used for the reconstruction of

bone defect made at the beagle dog mandible. Both HAp and CO

3

Ap demonstrated excellent tissue response. However, amount of

the bone formed at the bone defect was much larger in the case of CO

3

Ap when compared to HAp.

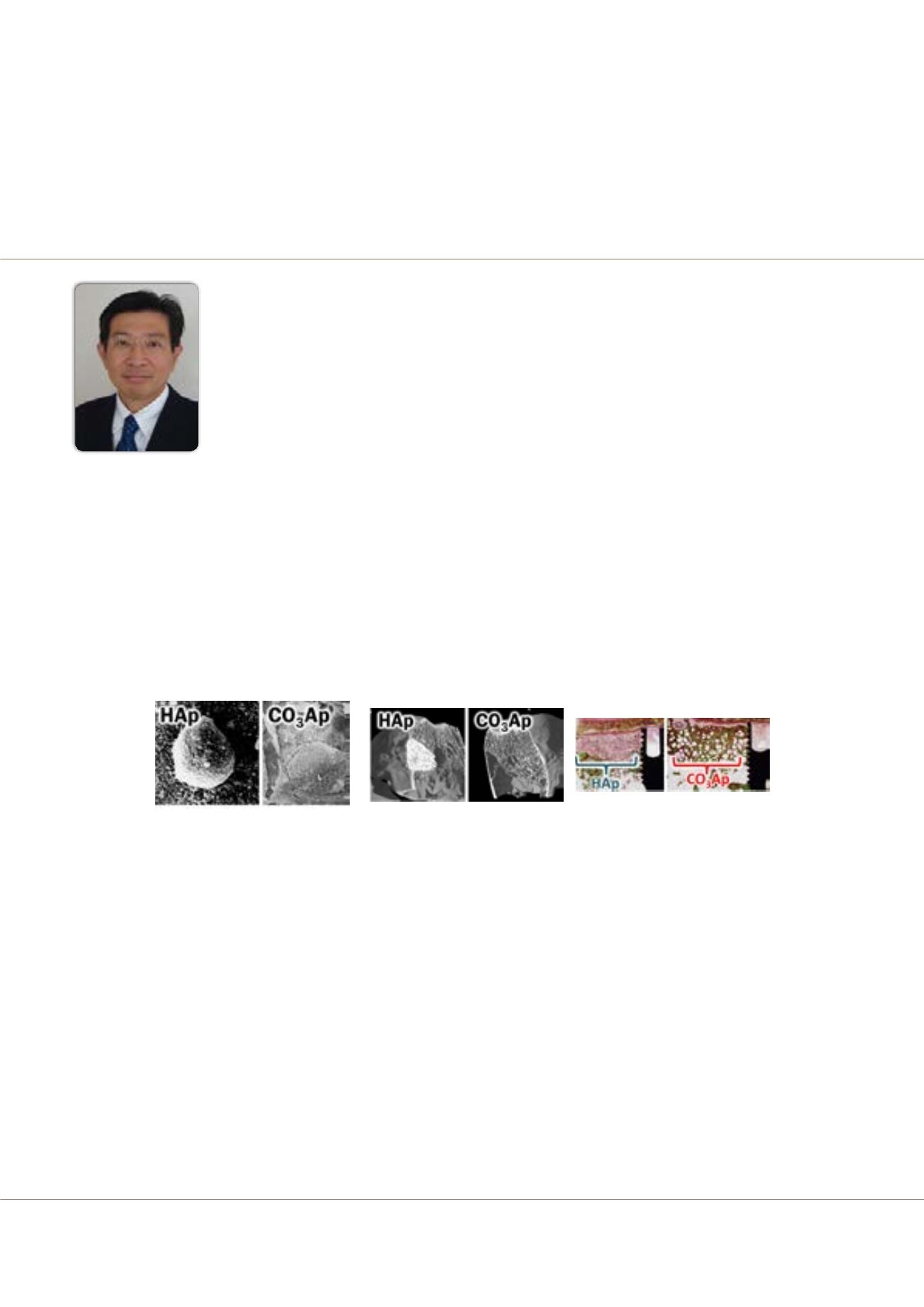

Figure 1: SEM images of HAp and CO

3

Ap when osteoclastic cells were incubated on their surfaces.

Figure 2: Micro-CT images of HAp and CO

3

Ap when used for the reconstruction of rabbit femur bone defect. 24 months after implantation.

Figure 3: Villanueva Goldner staining of HAp and CO

3

Ap when used for the reconstruction of bone defect at the beagle dog mandible. Three months after implantation

Recent publications

1. Ishikawa K, Kawachi G, Tsuru K and Yoshimoto A (2017) Fabrication of calcite blocks from gypsum blocks by

compositional transformation based on dissolution–precipitation reactions in sodium carbonate solution. Mater Sci &

Eng C, 51:389–393.

2. Shariff K A, Tsuru K and Ishikawa K (2017) Fabrication of dicalcium phosphate dihydrate-coated β-TCP granules and

evaluation of their osteoconductivity using experimental rats. Materials Science and Engineering C, 75:1411-1389–393.

Kunio Ishikawa

Kyushu University, Japan