Volume 8

Journal of Biotechnology and Biomaterials

ISSN: 2155-952X

Biomaterials 2018

March 05-06, 2018

Page 80

conference

series

.com

March 05-06, 2018 | Berlin, Germany

3

rd

Annual Conference and Expo on

Biomaterials

Mohamed Ansari M Nainar, J Biotechnol Biomater 2018, Volume 8

DOI: 10.4172/2155-952X-C1-087

Natural/Synthetic hybrid biocomposites: Sustainable materials

D

ue to environment and sustainability issues, biocomposites have encountered remarkable interest in the last two decades. Also,

due to the expanding waste management concerns, natural fibres composites have drawn the attention of many researchers in

this field. Hybrid polymer composites have embedded a series of natural and synthetic fibers. Each one has intrinsic characteristics

that, when combined to a polymer matrix, achieve a high performance and/or sustainable material [1]. One of the major concern

in the composite characteristics is the bonding between the reinforcements and the matrix [2]. Even though numbers of composite

materials with synthetic fibres such as glass fibres, rayon, nylon etc. and metallic fibres have been used as reinforcing agent but

natural fibres have uniqueness among them because of its extraordinary properties such as biodegradability with significant

strength and stiffness [3-5]. The purpose of this talk is to bring awareness among the scientist and researchers on introducing a cost

effective and cleaner method of improving the chemical interaction between the natural fibres and the polymer matrix through

hybridization techniques and minimize the water absorption problems that usually occur in pure natural fibre based polymer

composites. To improve on the properties of natural fiber composites and/or overcome some of their limitations such as moisture

absorption, thermal stability, brittleness and surface quality, the concept of hybridization of fibre reinforced composites was used

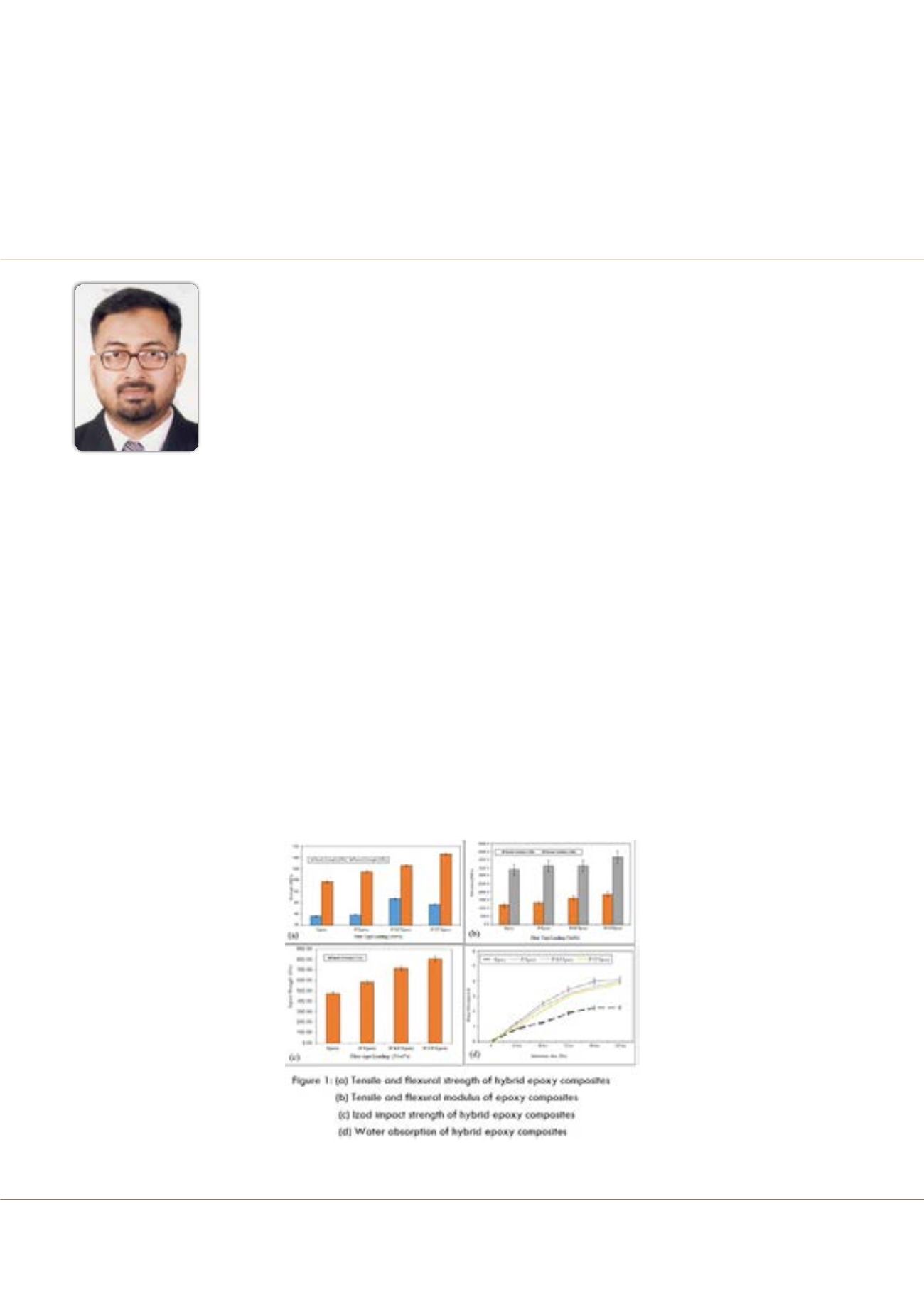

in this study. Jute fibre (JF)/Carbon fibre (CF) and Jute fibre (JF)/Kevlar fibre (KF) hybrid epoxy composites were prepared using

Vacuum Press Infusion (VPI) method. Tensile, flexural and impact tests were performed as per the ASTM standard methods. The

hybrid composites showed improvement in mechanical properties and reduced water absorption characteristics compared to Jute/

epoxy composites. Energy absorption characteristics have shown considerable improvement compared to pure epoxy and Jute/

Epoxy biocomposites as shown in Figure 1 (a) – (d).

Mohamed Ansari M Nainar

Universiti Tenaga Nasional, Malaysia