Page 32

Notes:

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

The poly(ethylene 2,5-furandicarboxylate): A new emerging biobased polyester from sugar stream

Nathanaël Guigo

1

, Nicolas Sbirrazzuoli

1

, Jesper van Berkel

2

and

Ed de Jong

3

1

University Nice Sophia Antipolis, France

2

Synvina, The Netherlands

3

Avantium Chemicals B.V., The Netherlands

P

oly(ethylene 2,5-furandicarboxylate) (PEF) is nowadays considered as a promising sustainable successor of poly(ethylene

terephthalate) (PET) for several reasons. First, PEF is fully biobased since it comes from the polycondensation of bio-based

ethylene glycol and 2,5-furandicarboxylic acid (FDCA) which is the chemical analogue of the terephthalic acid. FDCA is currently

produced by Synvina at pilot plant scale from a C6 sugars conversion process of vegetable biomass. Synvina - the joint venture

between Avantium and BASF - aims at building a world-leading reference plant with an annual production capacity of up to 50,000

metric tons of FDCA per year.

PEF possesses superior barrier properties and more attractive thermal properties (e.g., higher glass transition temperature and lower

melting point) than PET. The low CO

2

, O

2

and H

2

O permeability of PEF is a tremendous advantage for packaging applications. In

order to fill the requirements of industrial applications a deep knowledge of polymer structure-property relations is needed. An

important aspect for both the production and application of aromatic polyesters such as PEF is their crystallization behavior. Semi-

crystalline pellets/chips are used in the solid state polymerization reactor to avoid agglomeration or sticking during the process,

which are initially prepared by quiescent crystallization of medium molecular weight polyester. PEF crystals either formed from the

glass or from the melt show similar structures but the dynamic of crystal growth differs between the two crystallization pathways.

Moreover, annealing at temperatures close to the PEF melting point allowed obtaining information on PEF self-nucleation behavior.

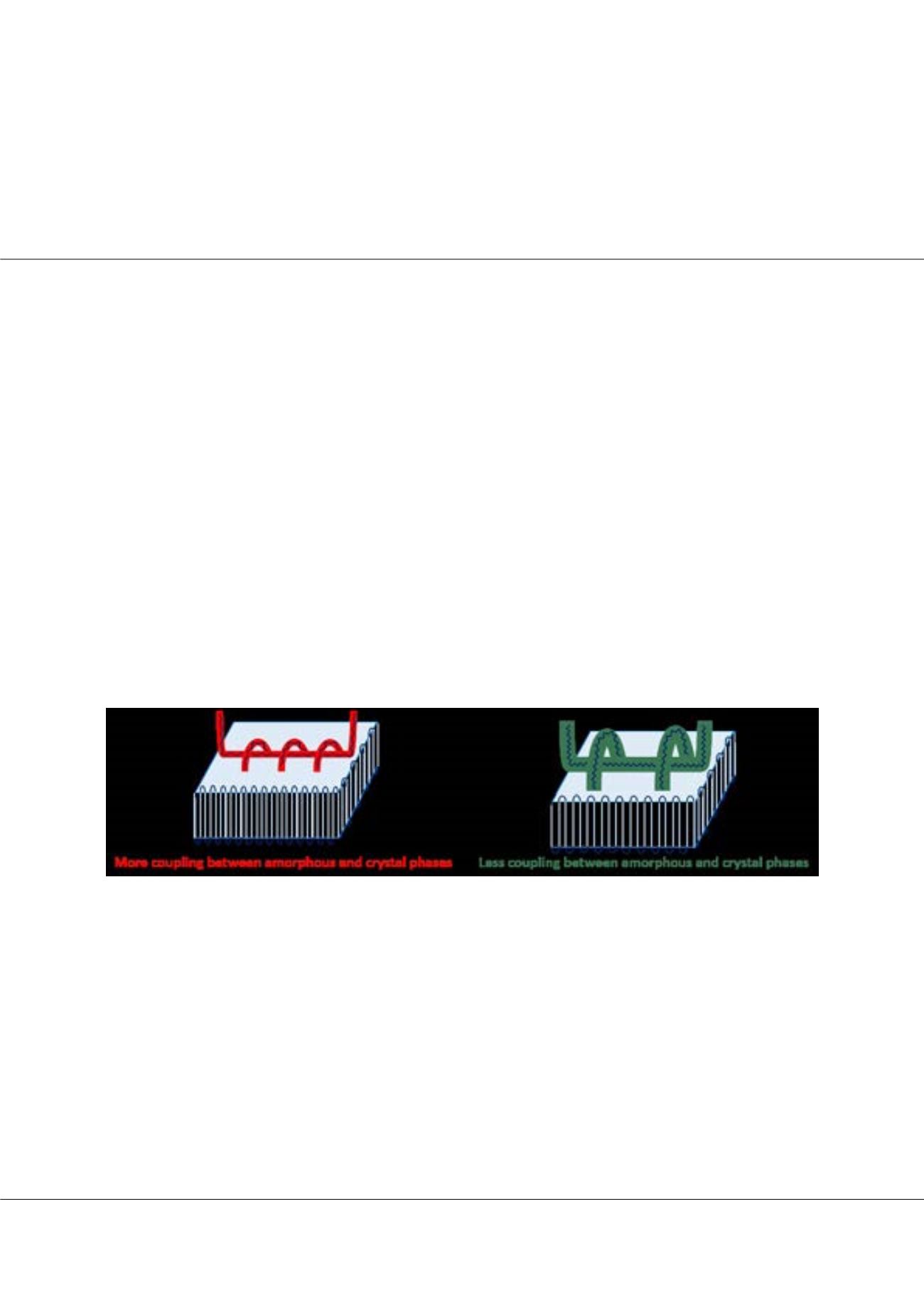

Finally, the restriction of the amorphous phase mobility by the presence of crystals is more limited in comparison with PET.

Biography

Nathanaël Guigo received his Ph.D. in 2008 from the University of Nice Sophia Antipolis (France) in the field of furanic based polymers. He joined the Centre de

Recherche sur les Macromolécules Végétales (Grenoble, France) as a post-doctoral fellow to work on cellulosic fibers in high performance composites. In 2010, he

became associate professor and in 2013, he obtained a secondment to Avantium (Amsterdam) to work on the poly(ethylene 2,5-furandicarboxylate). His scientific

work has been published in more than 35 papers or book chapter and he has been actively involved in three EU projects relative to the valorization of biomass

into new materials.

Nathanael.Guigo@unice.frNathanaël Guigo et al., J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-011

Figure 1: Sketch representing the coupling between the amorphous phase (red for PET and green for PEF) and the crystalline phase