Page 27

Notes:

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

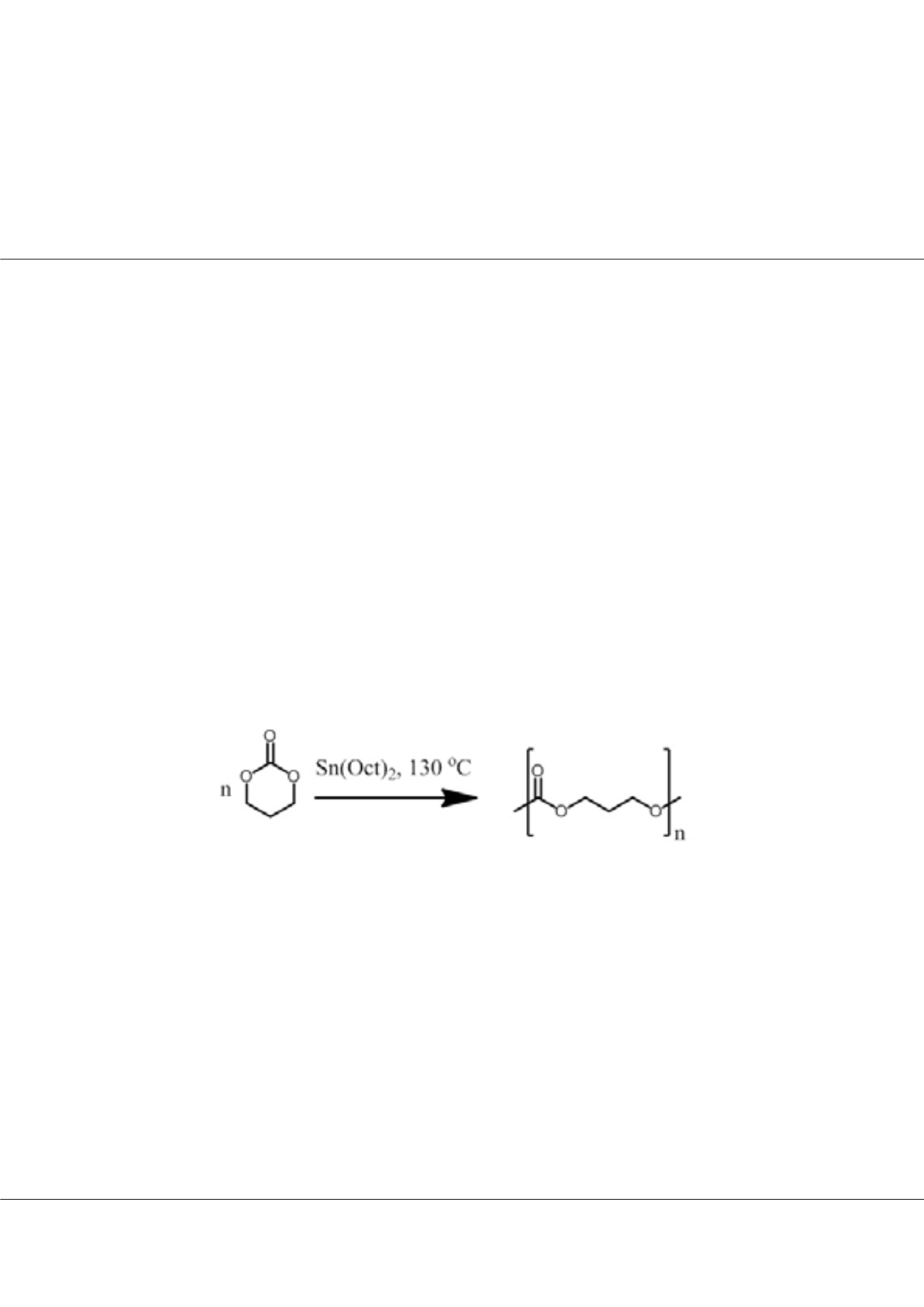

Poly(trimethylene carbonate) polymers and networks, Synthesis, properties and medical applications

Dirk W Grijpma

University of Twente, The Netherlands

P

oly(trimethylene carbonate) (PTMC) is an amorphous polymer with low glass transition, and is prepared by ring opening

polymerization of the cyclic trimethylene carbonate (TMC) monomer. It can be copolymerized with other lactone monomers

to yield materials with tuneable physical and chemical properties. Upon crosslinking flexible and elastic (co)polymer networks are

obtained, with properties that resemble those of poly(dimethyl siloxane) (PDMS) rubber. Interestingly, the TMC monomer can be

prepared from natural renewable resources using 1,3-propane diol that is obtained by fermentation of glucose.

While PTMC with number average molecular weights below 50000 g/mol are viscous or gummy materials with poor mechanical

properties, high molecular weight linear PTMC is an amorphous, tough and flexible solid with a low glass transition temperature of

-19 °C. The resistance to creep of the flexible polymer significantly increases when it is crosslinked. PTMC networks can be prepared

by gamma-irradiation of linear high molecular weight PTMC polymer or by photo-crosslinking functionalized macromers based on

TMC using UV-or visible light.

Materials based on PTMC are very useful in biomedical applications. Linear (co)polymers and (co)polymer networks prepared from

TMC and D,L-lactide or e-caprolactone were shown to be compatible with a large number of cells and implantation experiments in

small animals showed only a mild tissue response. PTMC based polymers and networks were found to degrade in the body by an

enzymatic surface erosion mechanism, without the release of acidic degradation products. This makes these polymers very well-

suited as a matrix in the preparation of biodegrade composite materials for bone tissue engineering and drug delivery.

Here we will present work on the synthesis and properties of PTMC polymers and networks, their processing into medical implants

by conventional processes and advanced additive manufacturing methods and their characteristics in the presence of cells and upon

implantation.

Biography

Prof. Dr. Dirk W. Grijpma is professor and head of the department of Biomaterials Science and Technology at the University of Twente. He also holds a part-time

professorship in the Development and Clinical Application of Biodegradable Polymers at the University Medical Center Groningen. His expertise is in the synthesis,

advanced processing and properties of (degradable) polymeric materials for use in medical devices, tissue engineering and in the delivery of relevant biologically

active compounds. His research also includes the interaction of these materials and devices with cells and tissues. He is editorial board member of Biomaterials,

Acta Biomaterialia, the Journal for Applied Biomaterials and Biomechanics, the Journal of Orthopedic Translation and the Journal of Medical Materials and

Technologies. He was elected Fellow Biomaterials Science and Engineering (FBSE) in 2008. Professor Grijpma is (co)author of more than 235 refereed scientific

publications and is (co)inventor on 24 international patent applications.

d.w.grijpma@utwente.nlDirk W Grijpma, J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-011

Figure 1: Ring-opening polymerization of trimethylene carbonate (TMC) using stannous octoate (Sn(Oct)2) as

catalyst to obtain high molecular weight poly(trimethylene carbonate) (PTMC).