Page 28

Notes:

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

Evaluation of thermoplastic starch and lignin as renewable fillers in styrene-butadiene rubber system

Sheng-Ju Liao, Shihn-Juh Liou

and

Chen-Yu Huang

Industrial Technology Research Institute, Taiwan

Statement of the problem: According to the Japan Rubber Manufacturers' Association, the total amount of carbon dioxide consumed

from each passenger tire is 296.4 kg. Approximate 87% (equivalent to 258 kg) of carbon dioxide is discharged at the stage of use.

The development of environmentally friendly energy-saving tires is the goal of global tires' manufacturers. Goodyear and Novamont

have collaborated to produce BioTRED using corn starch to replace parts of the lamp black and silica in rubber matrix. It has been

approved by both Ford and BMW. The purpose of this study is used non-food biomass resources such as typical starch and lignin

as renewable fillers in the styrene-butadiene system. Methodology & Theoretical Orientation: To develop the energy saving tires

with excellent wet traction and rolling resistance, the important fundamental properties such as viscoelastic behaviors of composite

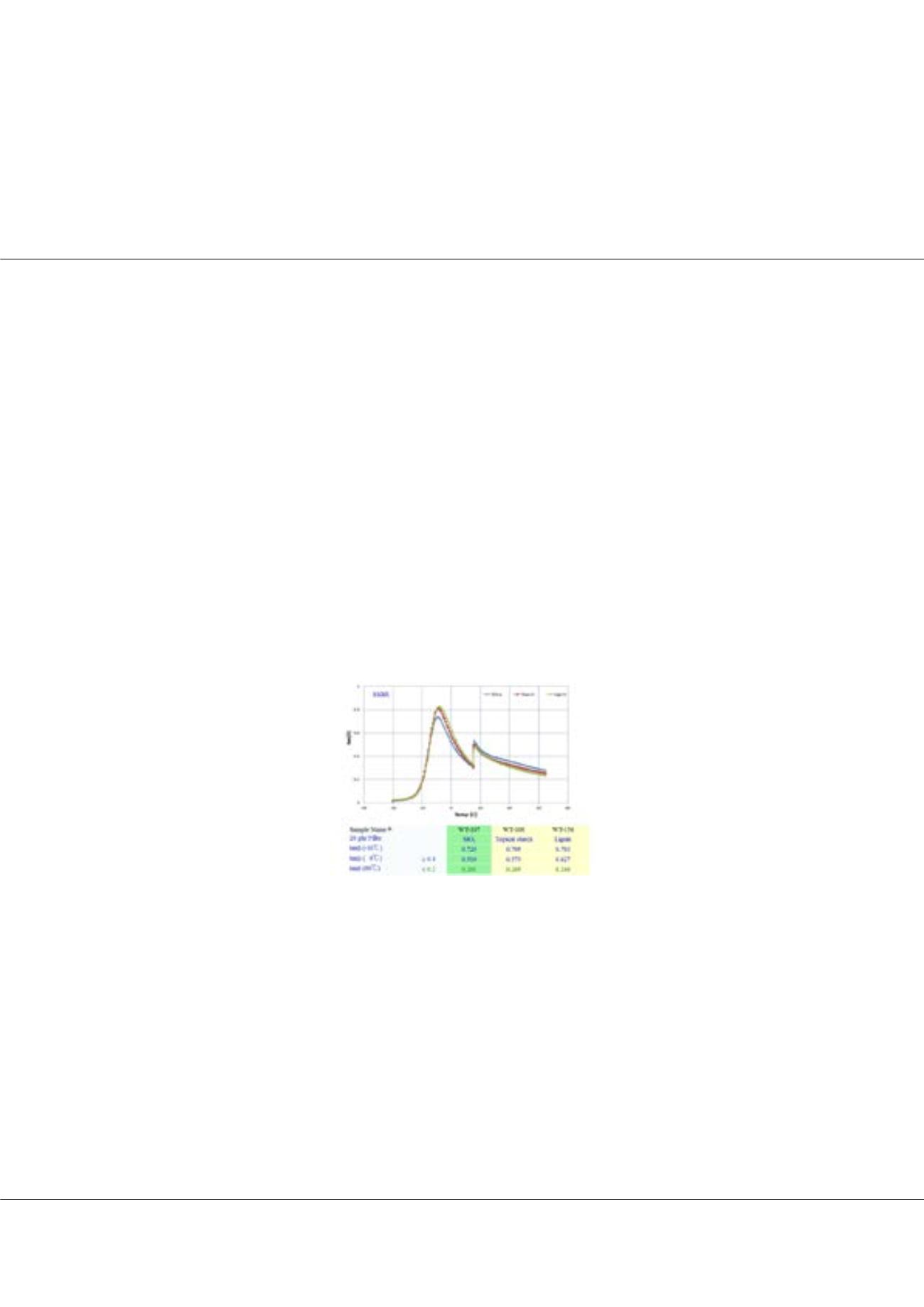

materials were investigated. Findings: Thermoplastic starch (TPS) and lignin bio-fillers were used to replace parts of the carbon

black and silica, which were normally contained in the tire tread mixture. The starch/lignin were incorporated from 5 to 20 parts

per hundreds of rubber (phr). Dynamic Mechanical Analyzer (DMA) test confirmed these two kinds renewable fillers are helpful for

improving wet grasping performance (i.e., evaluated at tan

δ

0

0

C) and reducing the rolling resistance (i.e., evaluated at tan

δ

60

0

C)

of tire tread. The Payne Effect test showed that the incorporation of 15 phr modified TPS to replace silica could improve dispersion

of reinforcing fillers in rubber composited system. Conclusion & Significance: There are many advantages by introducing non-food

biomass renewable fillers to styrene-butadiene rubber system. They can enhance tire wet grip, lower rolling resistance, and reduce

carbon dioxide emissions. There is also a “lightweight” advantage because the density of TPS is just half of silica. Moreover, the energy

saving processing can be reached.

Biography

Sheng-Ju Liao received her PhD degree in Chemistry from National Tsing Hua University, Taiwan. She works as a research fellow and project leader at Industrial

Technology Research Institute (ITRI), Taiwan. She has more than 10 years of R&D experience in the field of biocomposite materials. Her expertise includes biomass

monomer purification, polymerization, reactive extrusion, blending processing (e.g., injection molding, compression molding, and foaming), and assessment in

industrial application. She holds sixteen patents and several cooperated partners from the industry, such as BenQ, Chiaofu Group, Cheng Shin Rubber, Pou Chen

Group… etc...

SLLiao@itri.org.twSheng-Ju Liao et al., J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-011

Figure 1: Wet grip and rolling resistance evaluation of different kinds fillers