Page 34

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

The use of recycled polymer in the decrease of moisture in concrete slabs used in cemeteries

Luciana N Magalhães

1

, Juliana S. M. Guedes

3

, Stéphanie S. R. D. Morais

2

, Ariádina S. Menezes

2

and

Maria Alzira P. Dinis

3

1

University Pontifícia Universidade Católica, Brazil

2

FUMEC University, Brazil

3

University Fernando Pessoa, Portugal

T

he conventional concrete together with masonry are the building processes used in Brazil at the traditional cemeteries, named

horizontal cemeteries. They are, composed of shallow graves and burial chambers. The physical and mechanical characteristics of

the structural materials influence pathologies that may occur affecting both the integrity of the tombs and the environment in which

they are settled. The alkali-aggregate reaction, RAA, consists of a chemical reaction that occurs in mortars or concretes, between the

hydroxyl ions (OH-), mineralogical constituents of the aggregates, related to the alkalis sodium oxide (NA

2

O) and potassium oxide (

K

2

O) from the Portland cement itself or from other sources. The product of this reaction is the formation of the expansive gel, arising

from the deterioration process of the hardened concrete that causes from the destruction of structures and cracks, to the reduction

of tensile and compressive strengths. These pathologies affect the durability and safety of concrete structures, which are enhanced by

the presence of moisture. The higher the humidity, the greater the expansion. The lubricity comes from several conditions such as,

whether the water/cement factor is higher than necessary or the relative humidity is greater than 85%, among other reasons. Burial

buildings in cemeteries must be more resistant, due to the fact that in its internal space the very process of body decomposition and

the release of necroslurry attacks and affects the structure, in addition to external factors (environment), such as temperature, that

may wear out different types of materials. By increasing the polymer chain, the coefficient of expansion also expands, thus making

burial buildings more resistant. Permeability and oxidation are two of the most important chemical properties among others. To stop

humidity from enhancing the occurring pathologies, it is convenient to reduce this internal moisture in concrete structures with the

use of waterproof agents. Keeping this in mind, this article intends to evaluate the use of recycled polyethylene terephthalate (PET)

polymer in the structures of burial buildings at vertical cemeteries When evaluating the efficiency of these techniques, the state of

art of the vertical cemetery located in Recife, the capital of the state of Pernambuco, Brazil was assessed and taking into account the

lack of research approaching these subjects, the results of works developed in loco are presented. Advantages and drawbacks of the

application of polymers in the conventional concrete mix to reach the reduction of moisture. We have also pointed out proposals of

solutions concerning the conditions the structure is submitted to.

Biography

Luciana Nunes de Magalhães holds a degree in Civil Engineering from Universidade FUMEC, a master's degree and a PhD in Structural Engineering from

Universidade Federal de Minas Gerais. Currently, is a professor at Pontifícia Universidade Católica de Minas Gerais and provides updated courses for engineers

and architects in the construction / structural systems area at CREA MG. Has professional experience in the Structural Engineering field, besides publications in

magazines and congresses, with emphasis on those systems.

aldeialuciana@gmail.comLuciana N Magalhães et al., J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-011

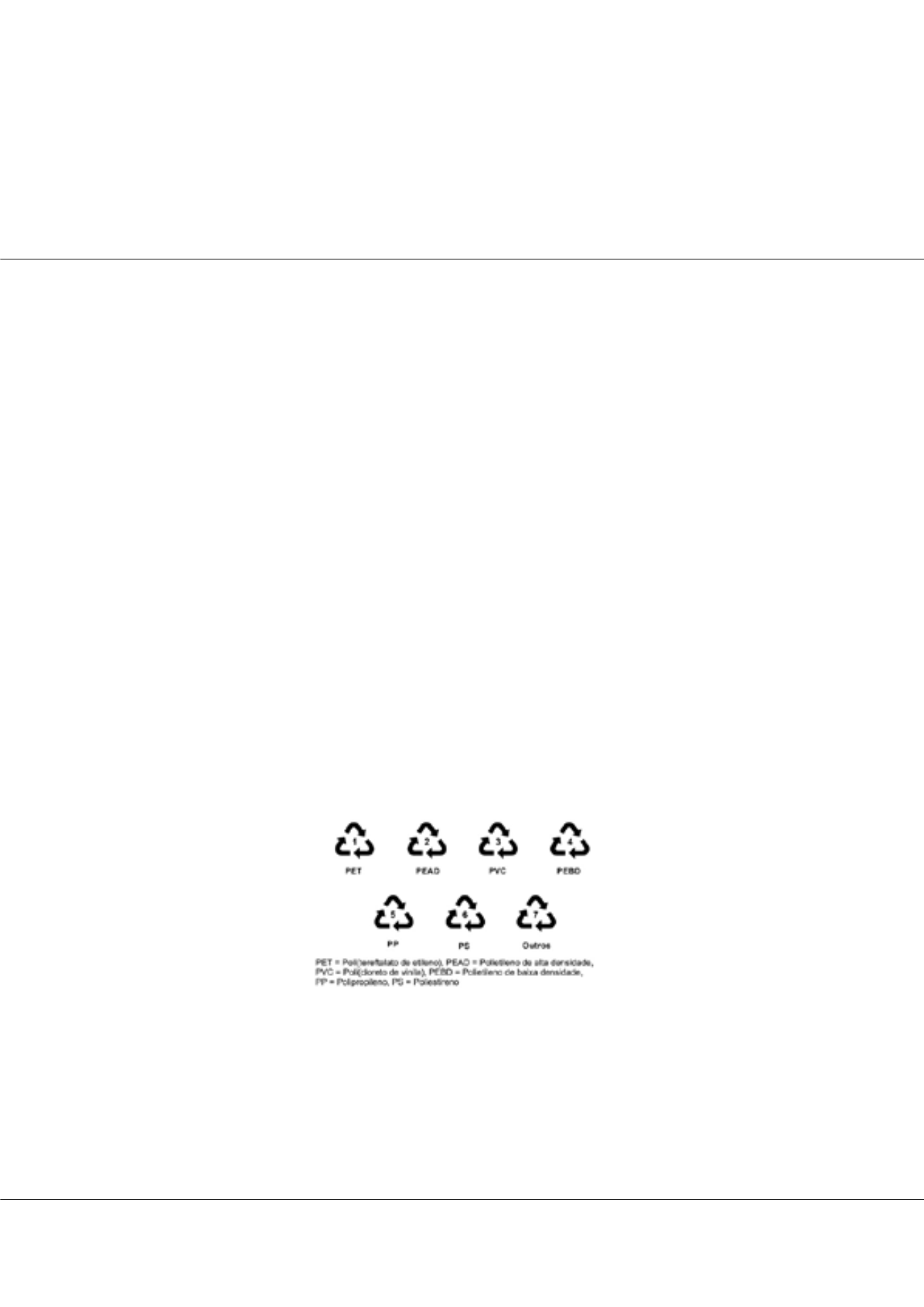

Figure 1 – Symbology used to identify polymer packages. Standard NBR 13.230 of ABNT (Brazilian Association of Technical Standards)