Page 39

Notes:

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

Developing a low temperature spinning process for polyhydroxyalkanoates

Bhavya Singhi

and

Martin W. King

North Carolina State University, USA

P

olyhydroxyalkanoates (PHAs), known as bacterial polyesters, are considered novel polymers because of their biodegradability.

A wide range of hydroxyalkanoate units, such as butyrates and valerates, are produced by bacterial synthesis. These units can

be polymerized and copolymerized with varying mechanical and structural properties. Due to their biocompatibility, PHAs have

been introduced in the fabrication of medical products, such as sutures and wound dressings. Some studies have explored the use

of bacterial polyester for controlled release applications with thermally sensitive chemicals and drugs. Since PHAs are melt spun at

temperatures as high as 200 °C, this requires a post spinning stage for chemical and drug incorporation. Hence, there is a need for

low temperature spinning of bacterial polyester to prevent drawbacks of post-spinning drug incorporation, such as a non-uniform

absorption that leads to an uneven release profile. To achieve this goal, we analyzed PHA solubility properties to develop a spinning

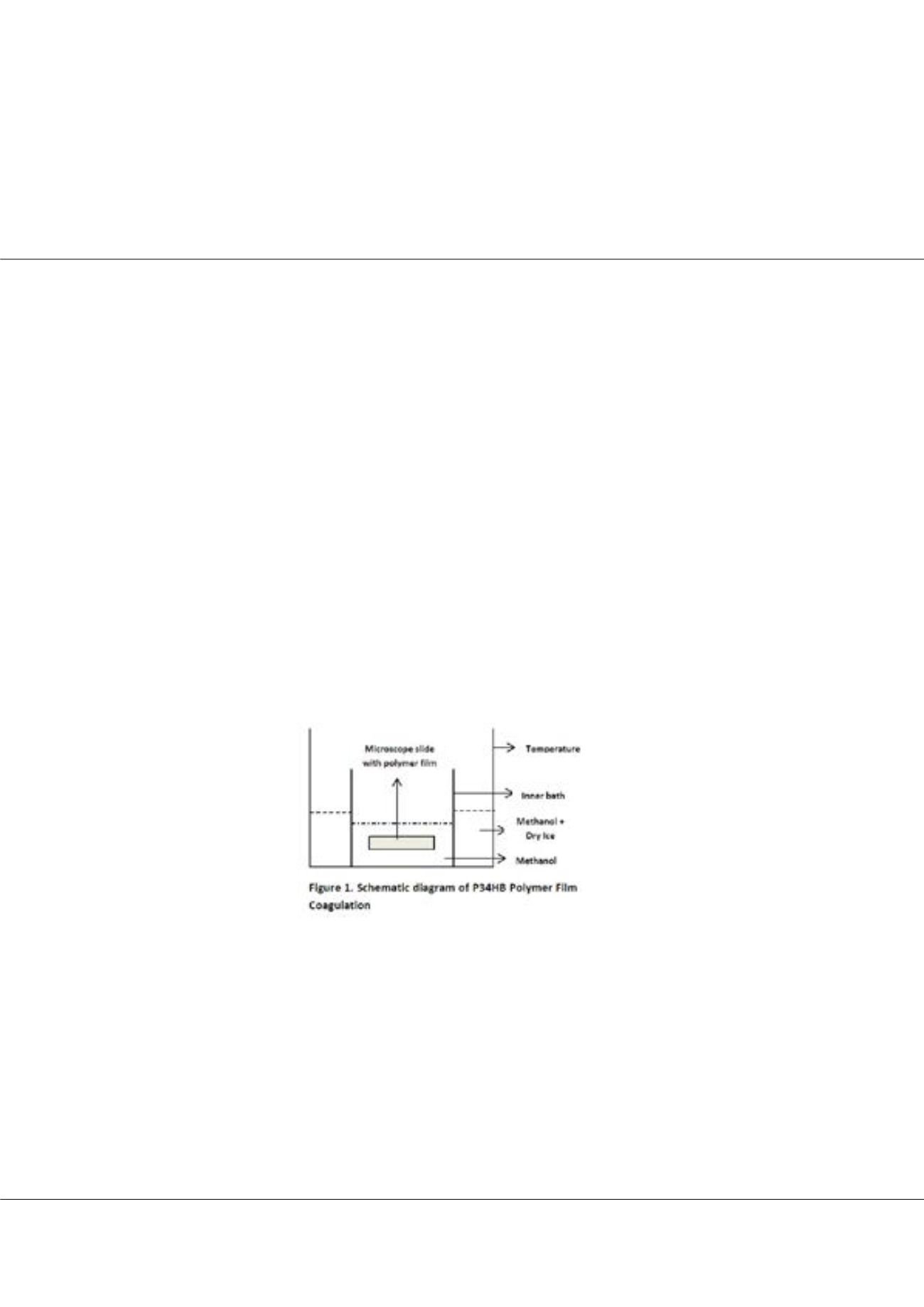

process at low temperature. Next we compared dissolution of poly(3-hydroxybutyrate-4-hydroxybutyrate) (P34HB) in multiple

solvents such as tetrahydrofuran, dioxane, methylene dichloride, and chloroform. This solvent study found methylene dichloride

as the most suitable solvent. As a result, polymer solutions of various concentrations were coagulated and regenerated as polymer

films in methanol at different temperatures to determine the optimal coagulating conditions. The polymer films were tested for their

thermal properties, molecular weight distribution and degradation profile. It was determined that the process used didn’t incur any

significant degradation in the polymer. Currently we are working on translating this process of making bacterial polyester polymer

films at low temperature to produce continuous filaments at low temperature. The project would further involve testing the process

by incorporation of drugs during spinning and determining a release profile for those drugs. This study would help in developing a

single step process for drug incorporation during fiber spinning, which can be utilized for drug delivery applications.

Biography

Bhavya Singhi is pursuing a PhD program in Fiber and Polymer Science at North Carolina State University, Raleigh. She graduated in 2016 with a master’s degree

in Textile Chemistry from NC State. Her undergrad degree was in Fibers and Textile Processing Technology from the Institute of Chemical Technology, Mumbai,

India. She has worked on various projects involving polymer technologies such as encapsulation, extrusion and synthesis. Her research interests include polymer

degradation, biopolymers and non-woven fabrics. She enjoys travelling, cooking and exploring new cuisines.

bsinghi@ncsu.eduBhavya Singhi et al., J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-011