Page 102

conferenceseries

.com

Volume 9

Journal of Bioremediation & Biodegradation

ISSN: 2155-6199

Biofuel Congress 2018 &

Biomass 2018

September 04-06, 2018

JOINT EVENT

September 04-06, 2018 | Zurich, Switzerland

13

th

Global Summit and Expo on

Biomass and Bioenergy

&

12

th

World Congress on

Biofuels and Bioenergy

Renewable resource-based material synthesized from lignocellulosic biomass

Chikako Asada, Chizuru Sasaki

and

Yoshitoshi Nakamura

Tokushima University, JAPAN

L

ignocellulosic biomass is made up three main component, i.e. cellulose, hemicelluloses, lignin, and expected as an alternative

resource of fossil resource. It is used to produce biofuels and biomaterials, and its increased use would lower environmental impacts

such as the emission of greenhouse gases and fossil fuel depletion. In East Asia, disposable wooden chopsticks are used in restaurants,

school cafeterias, and homes. The average annual amount of wooden chopsticks disposed of in Japan is about 90,000 t. Therefore,

disposable wooden chopsticks can be considered as a promising candidate for raw materials of useful fuel and chemicals production.

In this study the total biorefinary process of lignocellulosic biomass was developed using high temperature and pressure steaming and

milling treatment (SM treatment). Biorefinery is a process that produce fuels, power, heat, and value-added chemicals from biomass

using various pretreatment, extraction, separation, and conversion methods. The biorefinery concept is analogous to today's petroleum

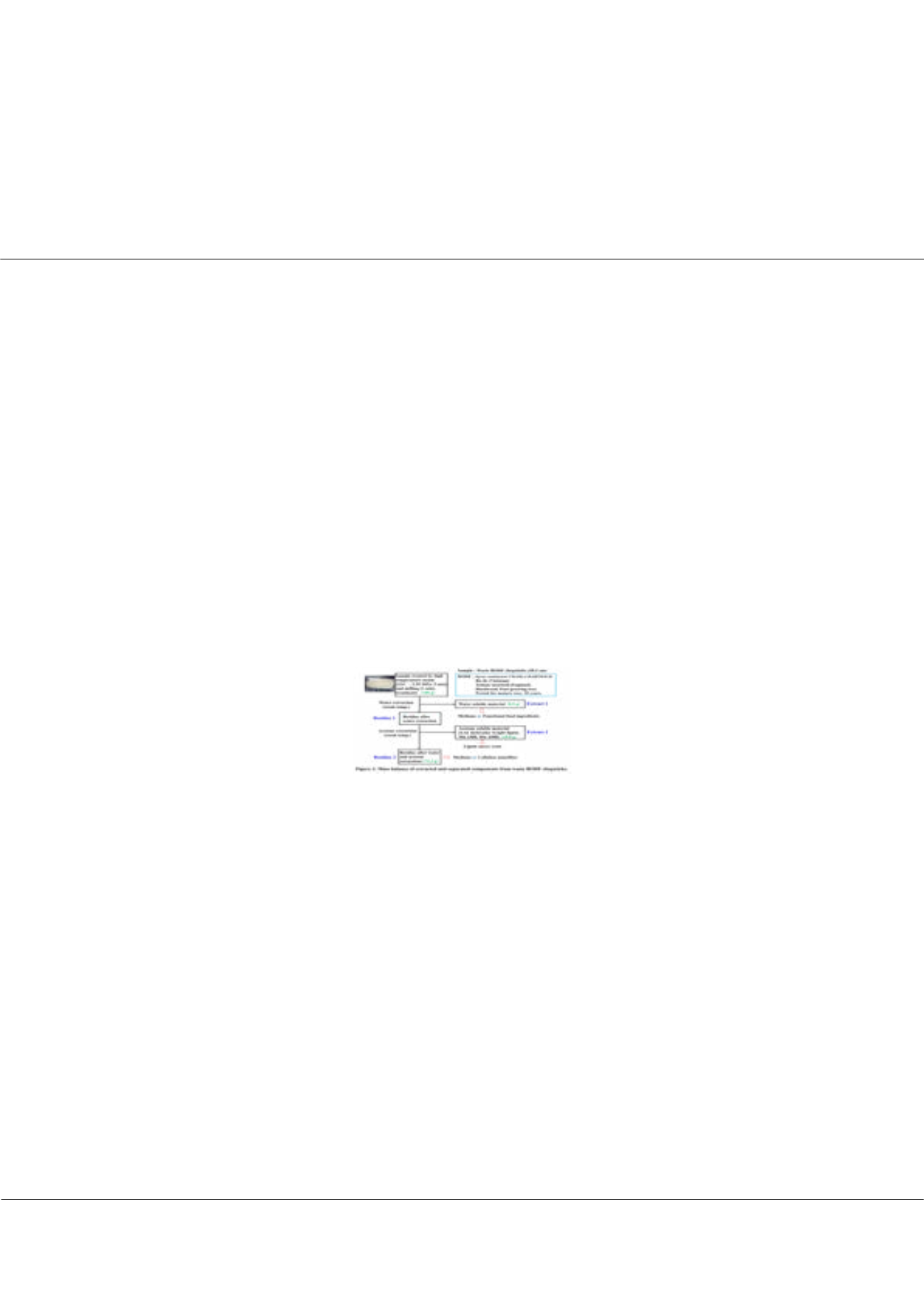

refinery, which produce multiple fuels and products from petroleum. We evaluated the efficient separation and utilization of woody

structural components from waste BODE chopsticks by using SM treatment followed by water and acetone extractions. The water

soluble material was converted into methane or functional food ingredients. Acetone soluble material (Low molecular weight lignin,

Mn 1300, Mw 4300) was used as not only a raw material for the synthesis of lignin epoxy resin but also curing agent for curing reaction

of epoxy resin. Residue after water and acetone extractions (Mainly cellulose component) was converted into methane or cellulose

nanofiber. Furthermore, the mechanical and thermal properties of cured lignin epoxy resin and cellulose nanofiber were evaluated. As

a result, we could show the mass balance of extracted and separated components from SM treated waste BODE chopsticks (Figure 1).

Recent Publications

1. Asada C, Sasaki C, Takamatsu Y, Nakamura Y (2015) Conversion of steam-exploded cedar into ethanol using

simultaneous saccharification, fermentation and detoxification process. Bioresource Technology 176: 203-209.

2. Asada C, Basnet S, Otsuka T, Sasaki C, Nakamura Y (2015) Epoxy resin synthesis using low molecular weight

lignin separated from various lignocellulosic materials. International Journal of Biological Macromolecules 74:

413-419.

3. Asada C, Sasaki C, Hirano T, Nakamura Y (2015) Chemical characteristics and enzymatic saccharification of

lignocellulosic biomass treated using high-temperature saturated steam: Comparison of softwood and Hardwood.

Bioresource Technology 182: 245-250.

4. Sasaki C, Yoshida Y, Asada C, Nakamura Y (2016) Total utilization of Japanese pear tree prunings: Extraction of

arbutin and production of bioethanol. Journal of Material Cycles and Waste Management 18: 385-292.

5. Suzuki A, Sasaki C, Asada C, Nakamura Y (2017) Characterization of cellulose nanofiber from steam-exploded

Japanese cedar. BioResource 12: 7628-7641.

Biography

Chikako Asada has her expertise in biomass effective utilization and bioremediation. She has completed her Ph.D. from Kanazawa University and studied about

biochemical engineering in Faculty of Bioscience & Bioindustry, Tokushima University. Currently she is studying on lignocellulosic biomass conversion technologies,

with expertise in synthesis of renewable-based materials from cellulose and lignin from plant biomass.

asada.c@tokushima-u.ac.jpChikako Asada et al., J Bioremediat Biodegrad 2018, Volume 9

DOI: 10.4172/2155-6199-C1-015