Page 100

conferenceseries

.com

Volume 9

Journal of Bioremediation & Biodegradation

ISSN: 2155-6199

Biofuel Congress 2018 &

Biomass 2018

September 04-06, 2018

JOINT EVENT

September 04-06, 2018 | Zurich, Switzerland

13

th

Global Summit and Expo on

Biomass and Bioenergy

&

12

th

World Congress on

Biofuels and Bioenergy

Development of a novel liquid-inerted microwave pyrolysis system

Benjamin Shepherd

and

John P Robinson

University of Nottingham, UK

P

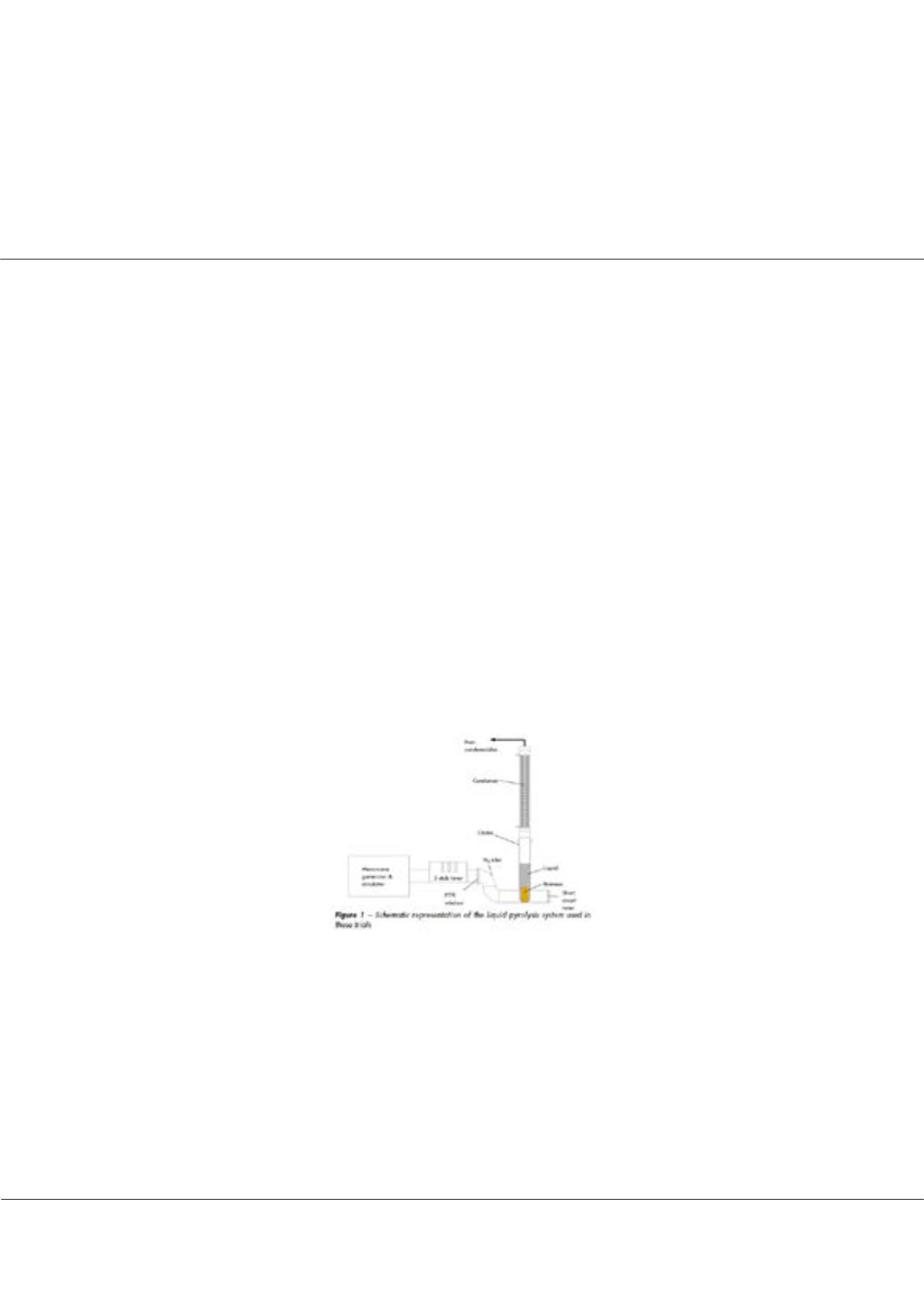

yrolysis is the thermochemical decomposition of biomass under inert conditions, into gas, oil and char. Microwave-

pyrolysis, which offers direct inherent heating advantages not provided by conventional heating, is an expanding area

of research. However, concerns exist with current state-of-the-art of microwave-pyrolysis systems used by researchers, as

they typically have low intensity microwave-fields, are arcing-prone and require a significant amount of inert gas. As such,

currently there is limited energy mass-balance information available due to the nature of these microwave reactors, which is

fundamentally needed to support the scalability potential of microwave-pyrolysis. In an effort to overcome the aforementioned

issues, a solvent inerted microwave-pyrolysis process has been developed and is presented here, offering benefits over gas

microwave-pyrolysis. These include: prevention of thermal-runaway as the solvent maintains the biomass between 300-500°C

due to increased thermal transfer, prevention of volatile secondary degradation reactions, provides heterogeneous heating-

profiles enabling larger samples to be processed. An inerting gas is not needed as volatiles are quenched directly into the

solvent, yielding bio-oil, reducing gas capture requirements and lowering process unit-costs. This presentation will focus on

the screening of nine solvents used to inert the pyrolysis of sycamore feedstock in a microwave-system, based on microwave

transparency/absorbency, boiling points, cost, environmental safety. Preliminary findings suggested that energy requirements

for pyrolysis are not significantly increased, selective depolymerisation of cellulose and hemicellulose is possible, pyrolysis

liquid yields can be as high as 70% of the bulk mass loss from the sample, and results fall in line with mathematic models. This

allows for potential of scale-up, and different pyrolysis liquid compositions to be compared to conventional and gas-inerted

microwave-pyrolysis. Future research and development, including: establishing how the solvent choice affects phase separation,

identification of key components in the oil and further processing scale-up, mass and energy balances and mathematical

models will also be discussed in this presentation.

Biography

Benjamin Shepherd is a 2

nd

year PhD Researcher at the University of Nottingham working under the supervision of Dr. John Robinson and Dr. Liam Ball. After

obtaining a MEng degree in Chemical Engineering in 2015 from the University of Nottingham, he decided to pursue research. His current research focuses on

the development of a novel microwave pyrolysis system that employs superior temperature control using inert liquid instead of gas. He performs a combination of

theoretical and empirical research in order to help underpin the process envelope for this new system.

Benjamin.shepherd@nottingham.ac.ukBenjamin Shepherd et al., J Bioremediat Biodegrad 2018, Volume 9

DOI: 10.4172/2155-6199-C1-015