Page 49

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

Polyethylene Furanoate: A promising biobased polyester for barrier applications

Andrea Arias

1

, Gregory Stoclet

2

, Laurent Degroote

3

, Bahar Yeniad

1

, Stephan Roest

1

, Sicco de Vos

1

1

Corbion Purac BV, The Netherlands,

2

Unité Matériaux et Transformations, Université Lille 1, France

3

Plastipak Europe, Belgium

P

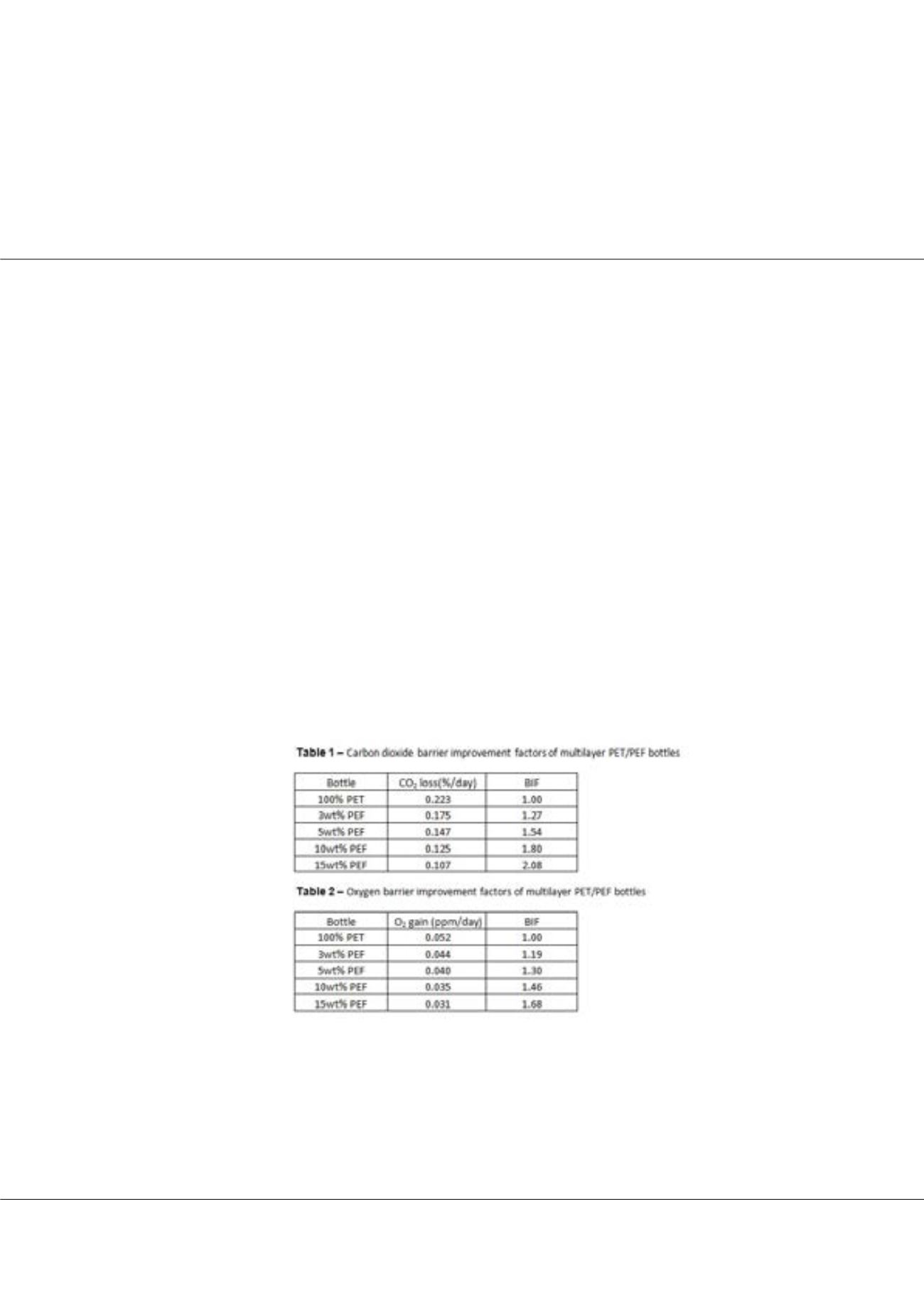

oly(ethylene furanoate) – PEF has gained extensive attention in recent years due to its high barrier properties to oxygen and carbon

dioxide. PEF is a biobased polyester polymerized through combination of 2,5-furandicarboxylic acid – FDCA and ethylene glycol.

Many authors consider PEF a potential replacement to PET and the next generation of FDCA biobased polyesters. The successful

introduction of PEF in the beverage and food packaging industry requires bringing concrete proof of its applicability and versatility

as a barrier layer, combining the fundamental understanding of the unique properties of PEF with the more practical aspects of

the tailored application development. The clarity and mechanical performance of PET have placed it as the material of choice for

manufacturing of packaging for carbonated soft drinks (CSD) juices and water. Multilayer packaging has been developed under the

principle to sandwich a high barrier material between PET layers in order to improve its undesirable low barrier to CO

2

and O

2

– often

a limitation of PET containers. In this talk the barrier enhancement properties of multilayer bottles using PEF as an intermediate

layer embedded in a PET CSD bottle will be presented. The manufacturing of preforms and bottles was accomplished using two-

stage injection stretch blow molding –ISBM. The weight percentage range of PEF in the bottle preform was defined at 3, 5, 10 and

15wt% and PET monolayer was used as a reference. The CO

2

permeation of multilayer PET/PEF bottles was studied over time under

standard conditions, i.e. 22°C and 50% RH. Table 1 shows the barrier improvement factor for each multilayer composition, which is

calculated as the ratio between the loss percentage per day using the monolayer PET as a reference. At the highest PEF wt.% studied,

i.e. 15wt%, the PEF medium layer contributes to CO

2

loss twice slower than PET monolayer bottles. For the same concentration, the

barrier to O

2

is improved by 70%, as it is depicted in Table 2. In addition to CO

2

and O

2

barrier performance, the relevant aspects

to the processing of PEF in typical pilot facilities involving the flow viscosity properties, temperature processing windows and melt

stability will be discussed as well.

Biography

Andrea Arias has built her expertise as a research engineer specialized in application development of biopolymers and biocomposites. She is experienced

in combining the fundamental understanding of the unique properties of bioplastics with the more practical aspects of the tailored product development. She

has a Bachelor degree in Chemical Engineering and she earned her Ph.D. degree in polymer science at Polytechnique School of Montreal when working with

nanocellulose applications for PLA-based composites. Andrea currently works as Application Specialist in the Biobased Innovations business unit of Dutch company

Corbion Purac. Corbion is the global market leader in lactic acid and lactic acid derivatives with over 80 years of fermentation experience. She's involved in the

FDCA to PEF value chain within the company.

andrea.arias@corbion.comAndrea Arias et al., J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-011