Page 56

Notes:

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

Production and characterization of nanobacterial cellulose (NBC) synthesized by

Glucanocetobacter

hansenii

using corn step liquor and PRODEX® as nitrogen source

Ana Paula Testa Pezzin, Haira.G. Hackbarth, Biassander C. Tureck, Michele Cristina Formolo Garcia, Giannini Pazisnick Apati and Andréa L. S. Schneider

University of Joinville Region (UNIVILLE), Brazil

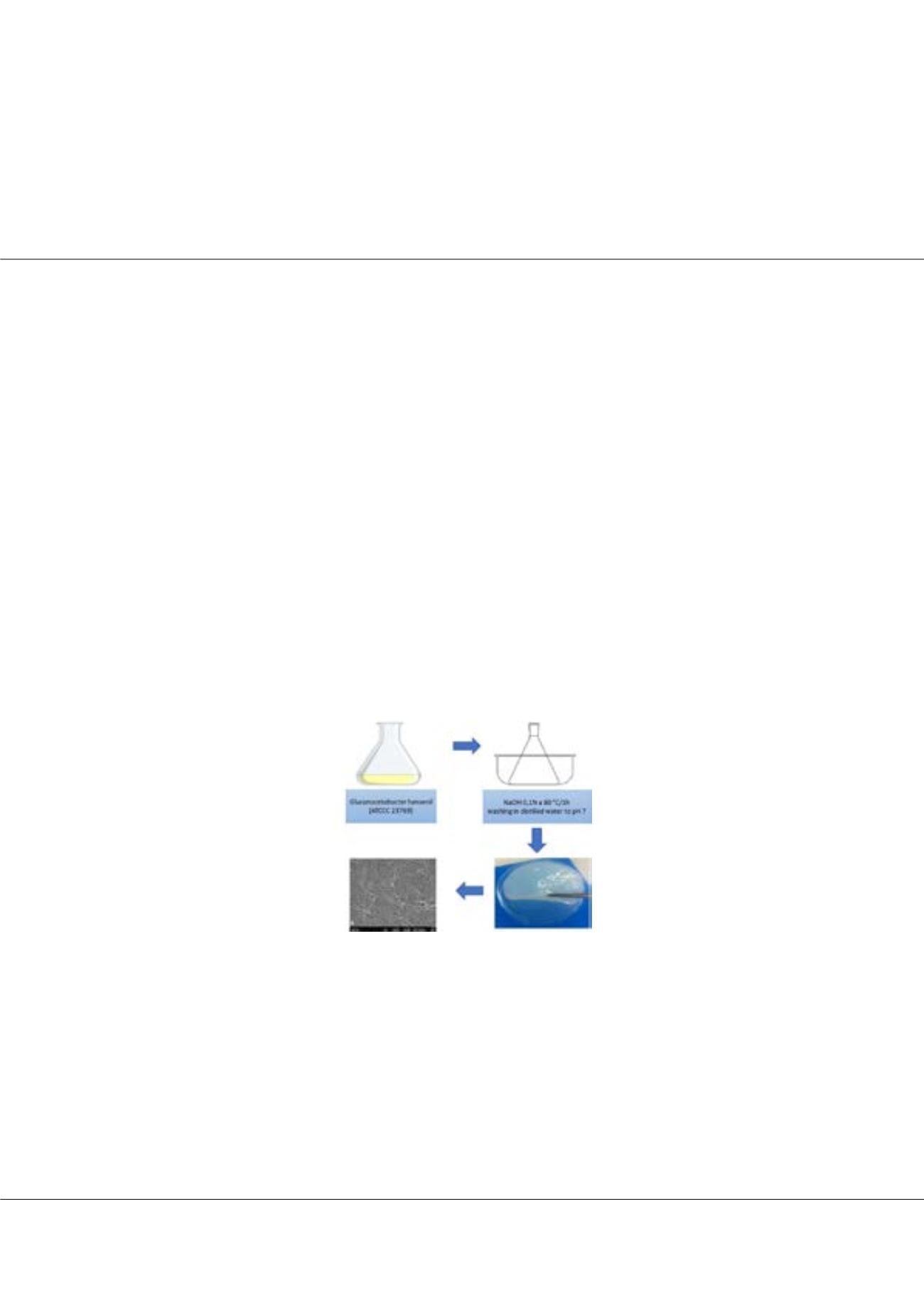

B

acterial nanocellulose (BNC) is an extracellular insoluble polysaccharide produced by some strains of

Gluconacetobacter

. BNC is

produced by

Gluconacetobacter hansenii

has specific physical and chemical properties that distinguish it from plant cellulose, such

as high crystallinity, chemical purity, mechanical strength, biocompatibility which leads BNC to become a new industrial material.

Althought, to produce BNC on a large scale, culture conditions must be optimized. Many different nutrients have been evaluating.

In this work, to evaluate the effect of different culture media, carbon and nitrogen sources were studied, seeking to optimize CB

production. Glucose, fructose, inulin, glycerol, lactose, sacarose, mannitol were verified as carbon source using corn steep liquor

and a crude yeast extract known commercially as Prodex Lac®, as nitrogen source. After culturing, cells were transferred at a 20%

inoculum rate to a 125 mL Erlenmeyer flask containing 20 g/L of the sugar to be investigated, 5 g/L Prodex Lac® (yeast autolysate,

nitrogen source) or 5 g/L corn (corn steep liquor, nitrogen source). The cultivation was kept static at 30ºC and sampling every 2

days for 12 days. After this period, the membranes formed were washed, dried and characterized (TGA, SEM and FTIR). The results

revealed that regardless of the nitrogen source, it was observed that all carbon sources result in the formation of BNC and the best

yields were found using fructose and mannitol. In the experiments that used fructose, the concentration of BNC was 2.484 g/L (corn

steep liquor) and 4.222 g/L (Prodex Lac®). The good performance of Prodex Lac® can be justified considering it is a crude yeast extract,

and the conventional medium for BC cultivation uses yeast extract and peptone as nitrogen sources. The obtained films presented

variations in the thermal degradation profile, in comparison to the one reported in the literature. This fact resulted in possible

impurities not completely removed with the purification method used. The FTIR analyzes did not differ from the literature, but also

showed some bands that indicate impurities in the CB sample.

Biography

Ana Paula Testa Pezzin graduated in Chemistry, Master in Chemical Engineering and PhD in Mechanical Engineering from the State University of Campinas. She

did postdoctoral studies at the Université Pierre et Marie Curie in Paris / France. She has been a leader in the POLYMERIC MATERIALS GROUP since 2001,

working in research lines: Polymeric biomaterials for medical and dental applications; Composites, biocomposites, nanocomposites and bionanocomposites;

Modification of biopolymers for different applications and synthesis and characterization of biopolymers by microbial culture. Currently, she is a Professor and

Researcher at the University of Joinville Region (UNIVILLE), being a level 2 productivity fellow at CNPq.

anapezzin@yahoo.com.brAna Paula Testa Pezzin et al., J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-012