Page 62

conferenceseries

.com

Volume 8, Issue 6 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN:2155-6199

Biopolymers & Bioplastics 2017

October 19-20, 2017

October 19-20, 2017 San Francisco, USA

7

th

International Conference and Exhibition on

Biopolymers and Bioplastics

Barrier properties in selecting the plasticizer for formulation of biopolymers pectin

Henado D Luz S

1

, Leal Q. Ahudrey

2

, Salazar P.J. Xiomara

1

1

Centro Agrindustrial SENA, Colombia

2

Tecnnoparque SENA, Colombia

C

olombia has a variety of fruits that are currently agroindustrialized generating organic residues composed of pectin, a

polysaccharide found in the shell of fruits like Passionfruit (Passiflora edulis Sims) being 60%; pectin possesses properties to

produce new biodegradable polymeric materials, but in the formulation must analyze characteristics like; the availability of raw

material, barrier and mechanical properties affected by the type and concentration of plasticizers. The objective of this study was

to standardize the extraction of high methoxyl pectin (HDM) and to identify the concentration and type of plasticizer to be used.

The complete shell was used to obtain pectin HDM, with extraction assisted by ultrasound varying the frequency between 12 kHz

and 20 kHz at 15 min and 30 min with pH of the solution at 2.5 and 3.0, as a variable response the interaction between factors for

% esterification of pectin. The film formation was performed by the casting method by mixing at 150 rpm / 60°C for 30 min the

pectin solution and the plasticizers glycerin (G), polyvinyl alcohol (PVA) at a concentration of 5, 10 and 15% and mixing G-PVA at

10-10%, 5-5% and 10-5% concentration, applying a selection matrix where water solubility and water vapor permeability interact.

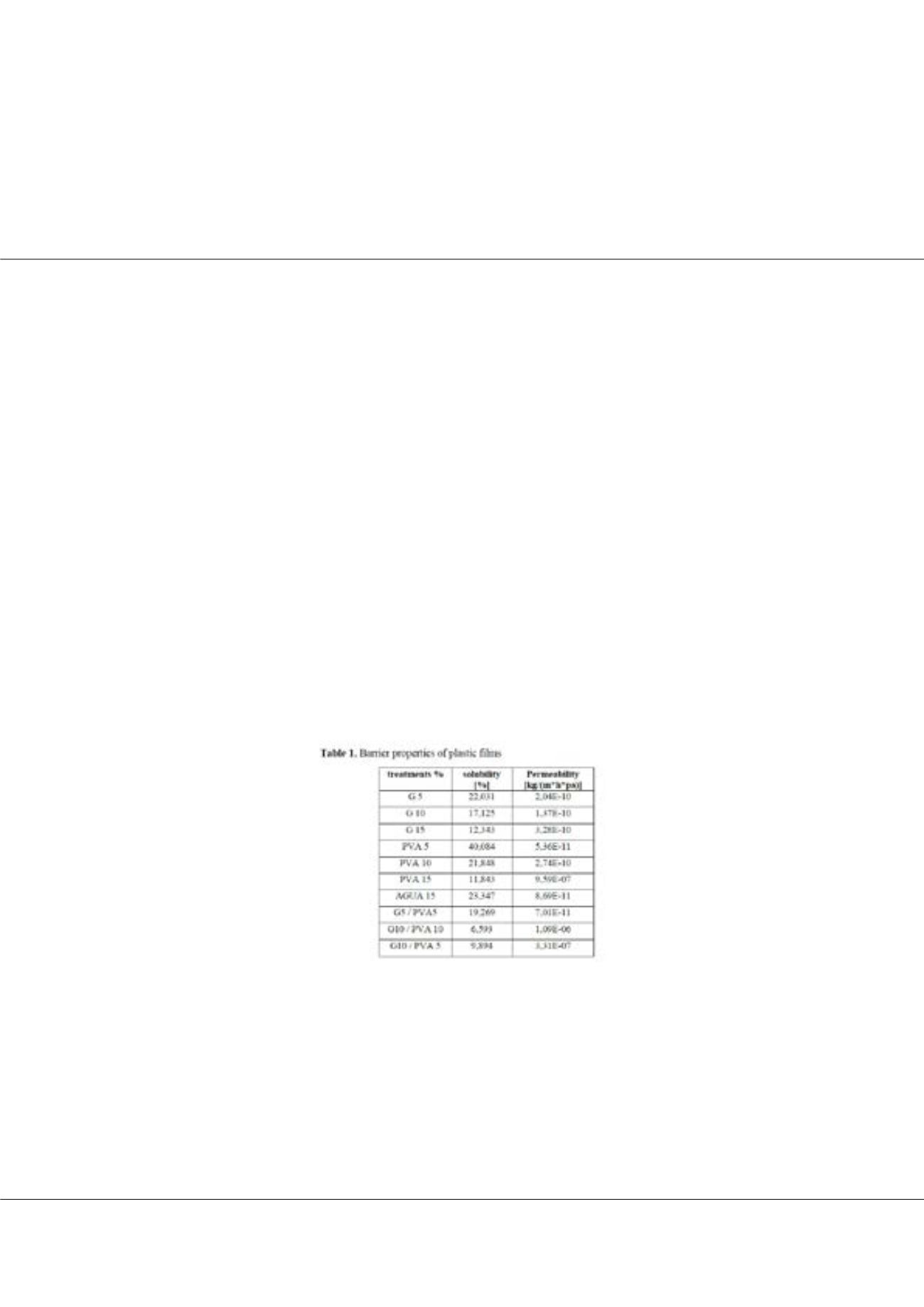

Applying ultrasound at 20 kHz for 15 min at pH 2.5 generated a pectin with 90% HDM. Regarding the barrier properties, the PVA

treatment at 5% concentration presented 40% un solubilized mass and the 10% -10% G-PVA treatment with lower value to water

vapor permeability. These results show that ultrasound promotes the release of polysaccharides thereby reducing exposure to high

temperatures while maintaining HDM property in the extraction; the physical properties of the barrier are inversely proportional,

the higher the concentration the less permeability to water vapor and the greater the solubility of the mass in water, compared with

recalcitrant polymers, the further improvement of the barrier properties of the mass in water, compared with recalcitrant polymers,

the further improvement of the barrier properties.

Biography

Ahudrey Leal Quintero I am a Magister in Advanced Biotechnology, with experience in the implementation of research, innovation and development programs in

technology-based entrepreneurship in areas such as; Biotechnology, Nanotechnology, Biopolymers. I am currently a project manager Tecnoparque SENA Node

Bogotá D.C. (Colombia) where the use of polysaccharide-rich agro-industry wastes has been used for the formulation of degradable agro-polymers in order to

reduce the environmental impact generated by the polymers.

ahudrey18@gmail.comLeal Q Ahudrey et al., J Bioremediat Biodegrad 2017, 8:6 (Suppl)

DOI: 10.4172/2155-6199-C1-012