Page 49

conferenceseries

.com

Volume 7, Issue 2 (Suppl)

J Adv Chem Eng, an open access journal

ISSN: 2090-4568

Euro Chemical Engineering 2017

November 16-17, 2017

ADVANCES IN CHEMICAL ENGINEERING AND TECHNOLOGY

November 16-17, 2017 | Paris, France

2

nd

International Conference on

The performance of dual-bed systemofMoS

2

/Al

2

O

3

andCo-MoS

2

/Al

2

O

3

catalysts inULSDproduction

from the mixture of rapeseed oil and SRGO

Irina V Deliy

1

, Evgenia N Vlasova

2

, Pavel V Aleksandrov

2

, Alexey L Nuzhdin

1

, Evgeny Yu Gerasimov

1

, Vera P Pakharukova

2

and

Galina A Bukhtiyarova

2

1

Novosibirsk National Research University, Russia

2

Boreskov Institute of Catalysis, Russia

T

he critical challenge in the developing of the energy-efficient co-processing of triglyceride-based feedstock with straight–

run gas oil (SRGO) for ULSD (ultra-low sulfur diesel) production is the elucidation of peculiarities of sulfide catalyst’s

behaviour depending on their chemical composition. It is known, that the triglycerides conversion over sulfide Co(Ni)Mo/

Al

2

O

3

catalysts proceeds through the deoxygenation (with the water formation) or via decarbonylation (with COx production)

pathways. But COx production is highly undesirable, because of ecological and technological reasons. In our work dual-bed

catalytic system is proposed for the co-processing of rapeseed oil (RSO) – SRGO mixture into ULSD. The Mo/Al

2

O

3

catalyst is

used in the front layer to provide RSO conversion without considerable COx formation, the SRGO hydrotreating proceeds over

traditional CoMo/Al

2

O

3

catalysts. CoMo/Al

2

O

3

, NiMo/Al

2

O

3

and dual-bed system (MoS

2

/Al

2

O

3

and Co-MoS

2

/Al

2

O

3

catalysts)

were compared in the hydrotreating of blended feedstocks (up to 45% of RSO) using full-sized commercial granules and

trickle-bed reactor. Total S, N, O contents and quality of produced fuels was checked using the corresponding ASTMmethods.

Characterization of the catalysts after reaction with TEM confirmed the formation of highly dispersed MoS

2

, CoMoS, and

NiMoS nanoparticles. It was observed, that over NiMoS/Al

2

O

3

catalyst ULSD can be produced from SRGO and RSO-SRGO

blends at the same conditions (at 4.0 MPa, 340

o

C, LHSV - 1,5 h-1, H

2

/C- 600), while the sufficient increase of temperature

is needed if the CoMoS/Al

2

O

3

catalyst is used. In the case of the dual-bed system, RSO content has only minor effect on the

catalyst efficiency in hydrotreating reaction, confirming that the decrease of HDS activity of CoMoS/Al

2

O

3

catalyst in presence

of RSO is due to CO inhibition. The use of dual bed system increase the products yield prevents COx formation and avoid the

necessity of costly and energy-intensive purification of recycle hydrogen in co-processing of RSO-SRGO mixtures.

Acknowledgement: The work was supported by the Ministry of Education and Science of the Russian Federation, unique

identificator RFMEFI57517X0128.

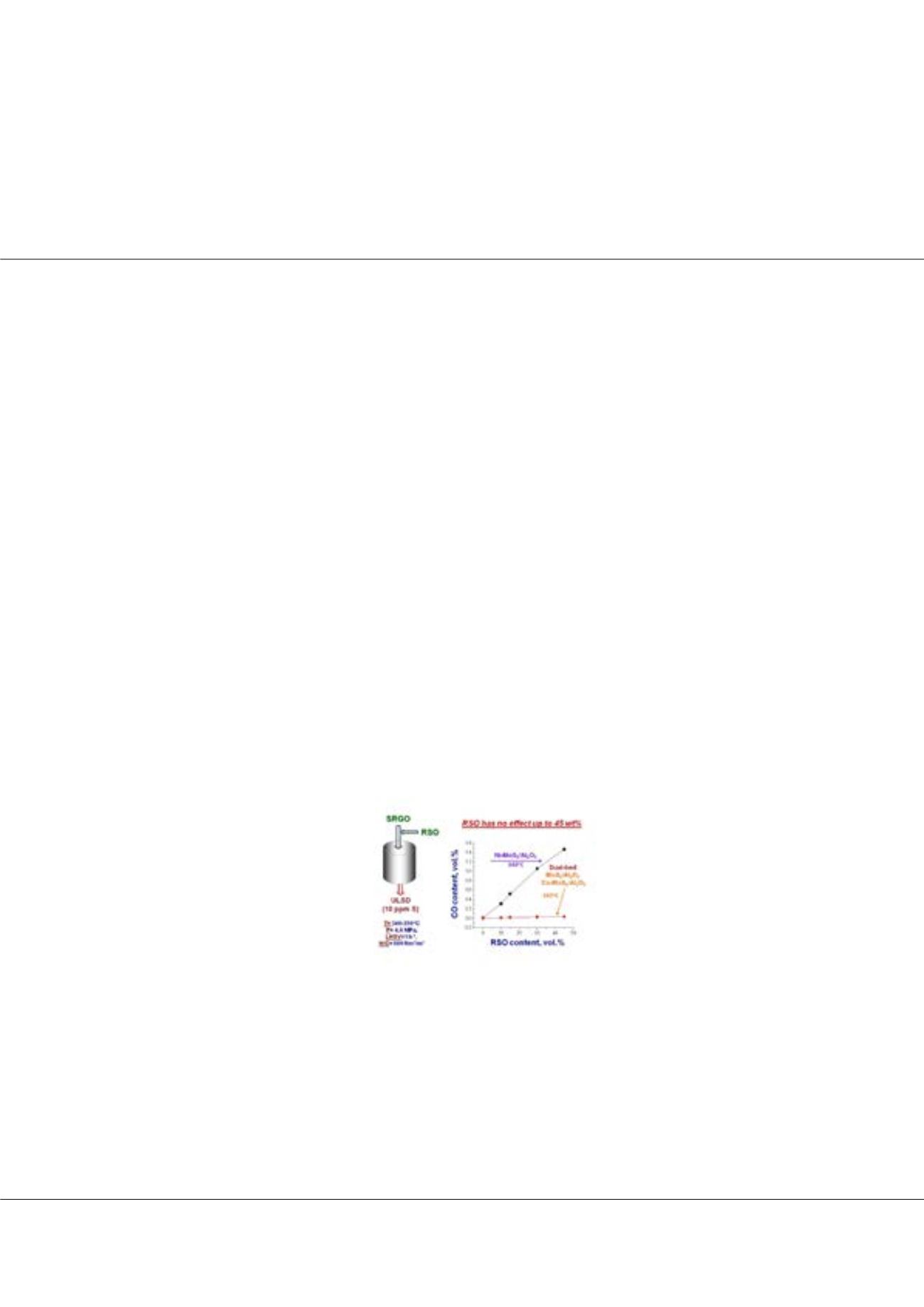

Figure1:

Effect of the rapeseed oil content on CO production during co-processing of rapeseed oil-SRGO mixture into ULSD over Ni-MoS2/Al2O3 and dual-bed system

Biography

Irina Deliy was graduated from Novosibirsk State University (2002) and completed her Ph.D. from Boreskov Institute of Catalysis, Novosibirsk, Russia (2009). She

is a senior researcher in Group of Hydrogenation processes at the Boreskov Institute of Catalysis and a researcher in Novosibirsk National Research University,

Russia. The main research topic is heterogeneous catalysis applied to renewable materials selective transformations. The main research topic is heterogeneous

catalysis applied to renewable materials selective transformations. Research activity has been mainly focused on the development of heterogeneous sulfide and

phosphide-based catalysts for the upgrading of renewable sources, such as vegetable oils and pyrolysis oil. Her scientific activity is summed up in 17 scientific

papers and 4 patents.

delij@catalysis.ruIrina V Deliy et al., J Adv Chem Eng 2017, 7:2(Suppl)

DOI: 10.4172/2090-4568-C1-002