Page 34

Notes:

conferenceseries

.com

Volume 7, Issue 2 (Suppl)

J Adv Chem Eng, an open access journal

ISSN: 2090-4568

Euro Chemical Engineering 2017

November 16-17, 2017

ADVANCES IN CHEMICAL ENGINEERING AND TECHNOLOGY

November 16-17, 2017 | Paris, France

2

nd

International Conference on

Chemical looping combustion and gasification technologies for production of heat and valuable

commodities

Ranjani Siriwardane

U.S. Department of Energy, USA

C

hemical-looping combustion (CLC) is a promising combustion technology that uses an oxygen carrier, such as metal

oxide, to transport oxygen to the fuel without exposing it to air. The significant advantage of CLC over conventional

combustion is that CLC can produce a sequestration-ready carbon dioxide (CO

2

) stream undiluted by nitrogen (N

2

) without

expending the major energy required for the separation of CO

2

. Large-scale application of CLC is dependent on the availability

of a suitable oxygen carrier. An ideal oxygen carrier should meet a number of requirements, including high reactivity, low

fragmentation and attrition, low tendency for agglomeration, low cost, and stability under repeated reduction/oxidation cycles

at high temperature.The carrier should also be environmentally benign. NETL researchers have developed and patented various

oxygen carriers containing copper oxide, iron oxide, and manganese oxide, all of which have shown promising performance.

Successful commercial-scale preparations and pilot-scale tests have been performed with these NETL-developed oxygen

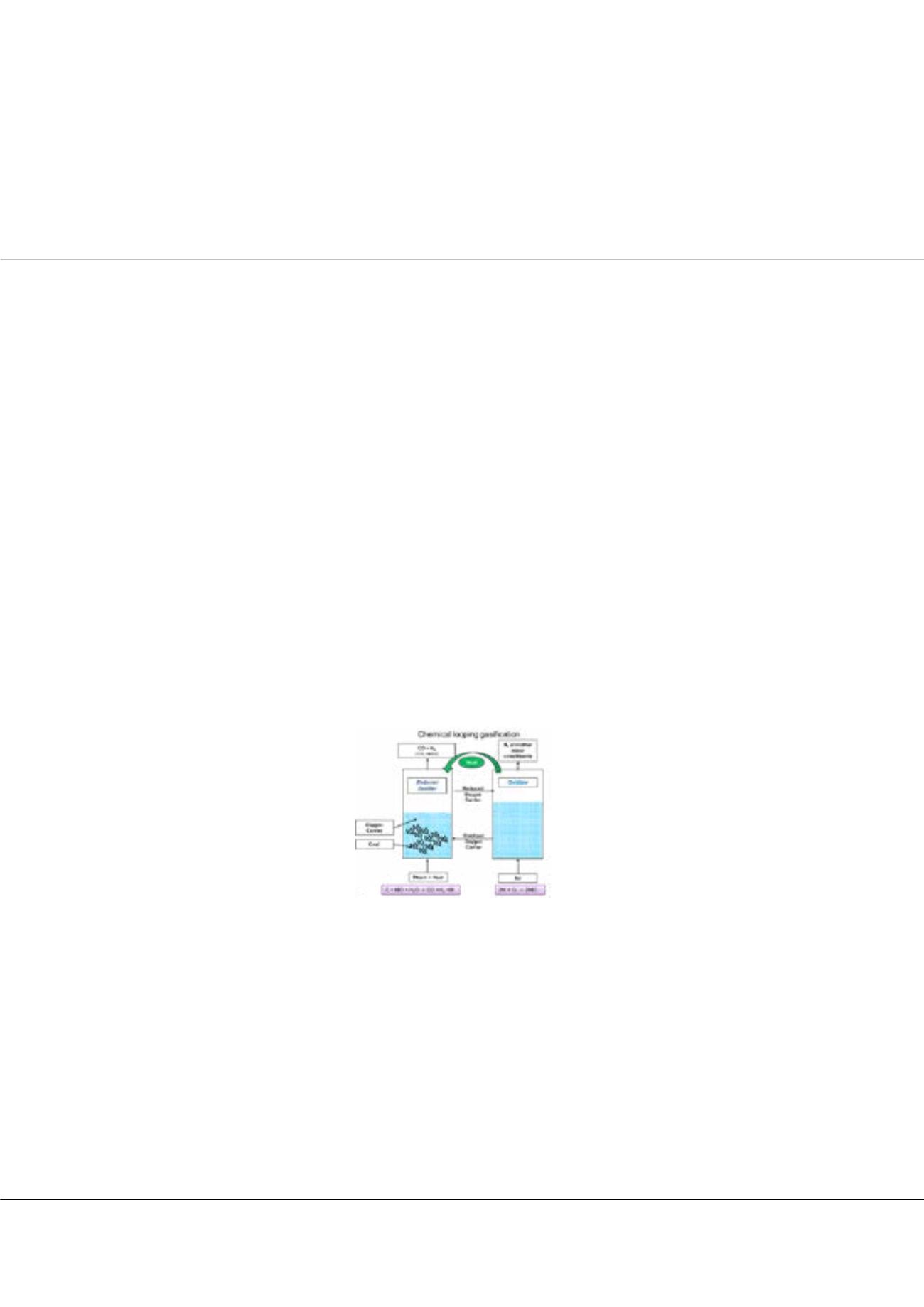

carriers. Beside the combustion reaction, chemical looping concepts have been proposed to produce hydrogen or synthesis

gas from coal and methane. Chemical looping gasification of coal using oxygen carriers will produce a concentrated syngas

stream undiluted with nitrogen. Chemical looping coal gasification will not require an air separation unit—a major advantage

over traditional coal gasification, which uses air. However, development of oxygen carriers for gasification has been a challenge

because most oxygen carriers combust fuels. NETL researchers have developed oxygen carriers containing calcium ferrite and

barium ferrite for chemical looping coal gasification to produce syngas. These unique oxygen carriers selectively react with

coal to produce syngas but do not combust the syngas. Chemical looping technologies for heat generation and production of

syngas, which is a precursor for production of valuable commodities, will be discussed.

Biography

Dr. Ranjani Siriwardane is a research scientist at the U.S. Department of Energy’s (DOE) National Energy Technology Laboratory (NETL). She leads the oxygen

carrier development research work in both chemical looping combustion and chemical looping gasification at NETL. Dr. Siriwardane has also conducted research

on development of sorbents for CO

2

removal and hydrogen sulfide and hydrogen chloride removal from coal gasification gas streams. She is a co-inventor of 19

U.S. patents, 7 U.S. patent applications, and has co-authored 80 peer-reviewed publications. She has won three R&D 100 awards. She has designed sorbents/

oxygen carriers from lab-scale to pilot-scale operations and has licensed her patents to three U.S. companies.

Ranjani.Siriwardane@netl.doe.govRanjani Siriwardane, J Adv Chem Eng 2017, 7:2(Suppl)

DOI: 10.4172/2090-4568-C1-002