Page 94

conferenceseries

.com

Volume 9

Journal of Bioremediation & Biodegradation

ISSN: 2155-6199

Biofuel Congress 2018 &

Biomass 2018

September 04-06, 2018

JOINT EVENT

September 04-06, 2018 | Zurich, Switzerland

13

th

Global Summit and Expo on

Biomass and Bioenergy

&

12

th

World Congress on

Biofuels and Bioenergy

The strategic use of sugarcane for second-generation ethanol production: Cold alkaline extraction

pretreatment

Danila Morais de Carvalho, Olena Sevastyanova, José Humberto de Queiroz

and

Jorge Luiz Colodette

Royal Institute of Technology, Sweden

T

he global demand for more sustainable alternatives for supplying fuels, energy, chemicals, materials etc. has attracted

great attention of researchers and industries currently. The increasing use of lignocellulosic biomass as feedstock is a

good example about how industry has investigated potential substitutes for the traditional fossil sources. The ethanol is an

alcohol usually obtained from renewable sources by fermentation process and widely used for chemical and fuel purposes. In

tropical areas, the main feedstock for ethanol production is the sugarcane, from which only the sugarcane juice is used within

the production process. However, the strategic use of its lignocellulosic residues,

i.e.

bagasse and straw, in technologies for

second-generation ethanol production presents great logistic advantages, with potential for enhancing the sugarcane industry

profitability by integrating first and second-generation platforms. The second-generation ethanol production, however, faces

nowadays some challenges to be commercially implemented, being one of them the biomass pretreatment. The cold alkaline

extraction (CAE) is an efficient method to remove substantial amounts of hemicelluloses and lignin from biomasses. Performed

in low temperature (20-40°C), CAE requires just relatively simple instrumental (unpressured reactor). In the present study we

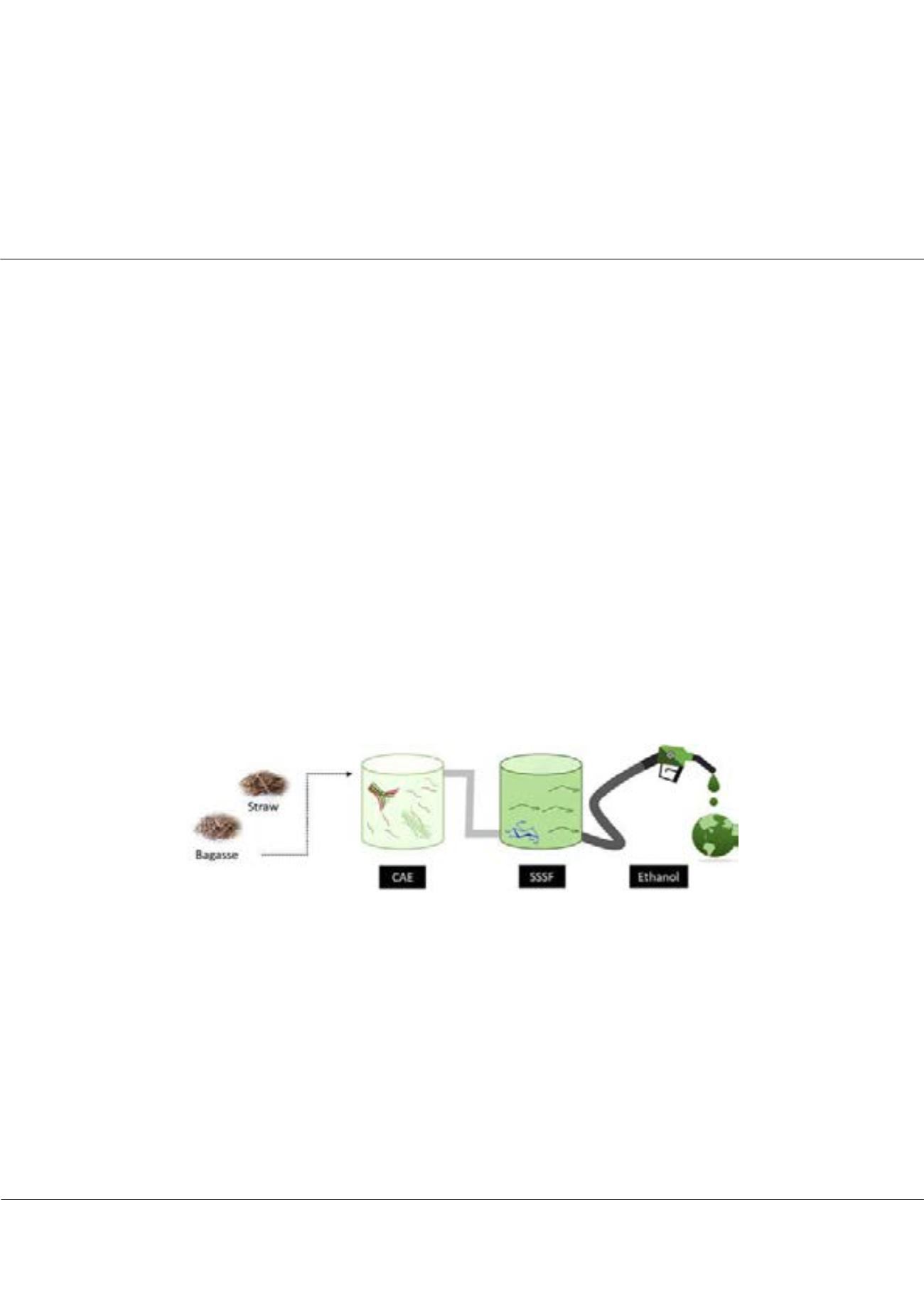

investigated the CAE pretreatment for bagasse and straw preparation and the ethanol production through semi-simultaneous

saccharification and fermentation (SSSF) (Fig. 1). To the best of our knowledge, although used in other industrial segments,

the use of CAE for treating biomass for ethanol production had not been explored before, especially in combination with

SSSF. A removal of 52-61% xylan and 37-45% lignin from biomasses was observed during CAE process. Biomasses depleted

in hemicelluloses and lignin were more susceptible to SSSF process, increasing the volumetric productivity of ethanol in 11.6

times and 15 times compared with untreated bagasse and straw, respectively. The volumetric productivity of ethanol was 0.29

g/L/h and 0.57 g/L/h for bagasse and straw, respectively.

Figure 1:

Working plan for second generation ethanol production from sugarcane bagasse and straw using cold alkaline extraction pretreatment.

Recent Publications

1. Carvalho DMde, Queiroz JHde, Colodette JL (2017) Hydrothermal and acid pretreatments improve ethanol production

from lignocellulosic biomasses. BioResources 12(2):3088‐3107.

2. Carvalho DMde, Colodette JL (2017) Comparative study of acid hydrolysis of lignin and polysaccharides in biomasses.

BioResources 12(4):6907‐6923.

3. Carvalho DMde, Queiroz JHde, Colodette JL (2016) Assessment of alkaline pretreatment for the production of biethanol

from eucalyptus, sugarcane bagasse and sugarcane straw. Industrial Crops and Products 94:932‐941.

4. Carvalho DMde, Sevastyanova O, Queiroz JHde, Colodette JL (2016) Cold alkaline extraction as a pretreatment for

bioethanol production from eucalyptus, sugarcane bagasse and sugarcane straw. Energy Conversion and Management

124:315‐324.

Danila Morais de Carvalho et al., J Bioremediat Biodegrad 2018, Volume 9

DOI: 10.4172/2155-6199-C1-014