Page 89

conferenceseries

.com

Volume 7

Biosensors Journal

ISSN: 2090-4967

Electrochemistry 2018

June 11-12, 2018

June 11-12, 2018 | Rome, Italy

4

th

International Conference on

Electrochemistry

Experimental study on conductivity versus concentration of electrolytes for electrochemical deburring

process

Alay Patel, Harsh Thakkar, Satisha Prabhu, Abhishek Kumar

and

Vishvesh Badheka

Pandit Deendayal Petroleum University, India

Statement of the Problem:

Electrochemical deburring (ECD) is a widely popular process among industries to manufacture

miniature parts and intricate components. Hence, it is important to optimize its process parameters to obtain high material

removal rates and cost efficiencies. The domain of this paper focuses on the electrolyte types and control over the variation of

its concentration during ECD operations. Here, a technique is developed to maintain a set value of electrolyte concentration

based on its relation with the electrical conductivity of electrolytes.

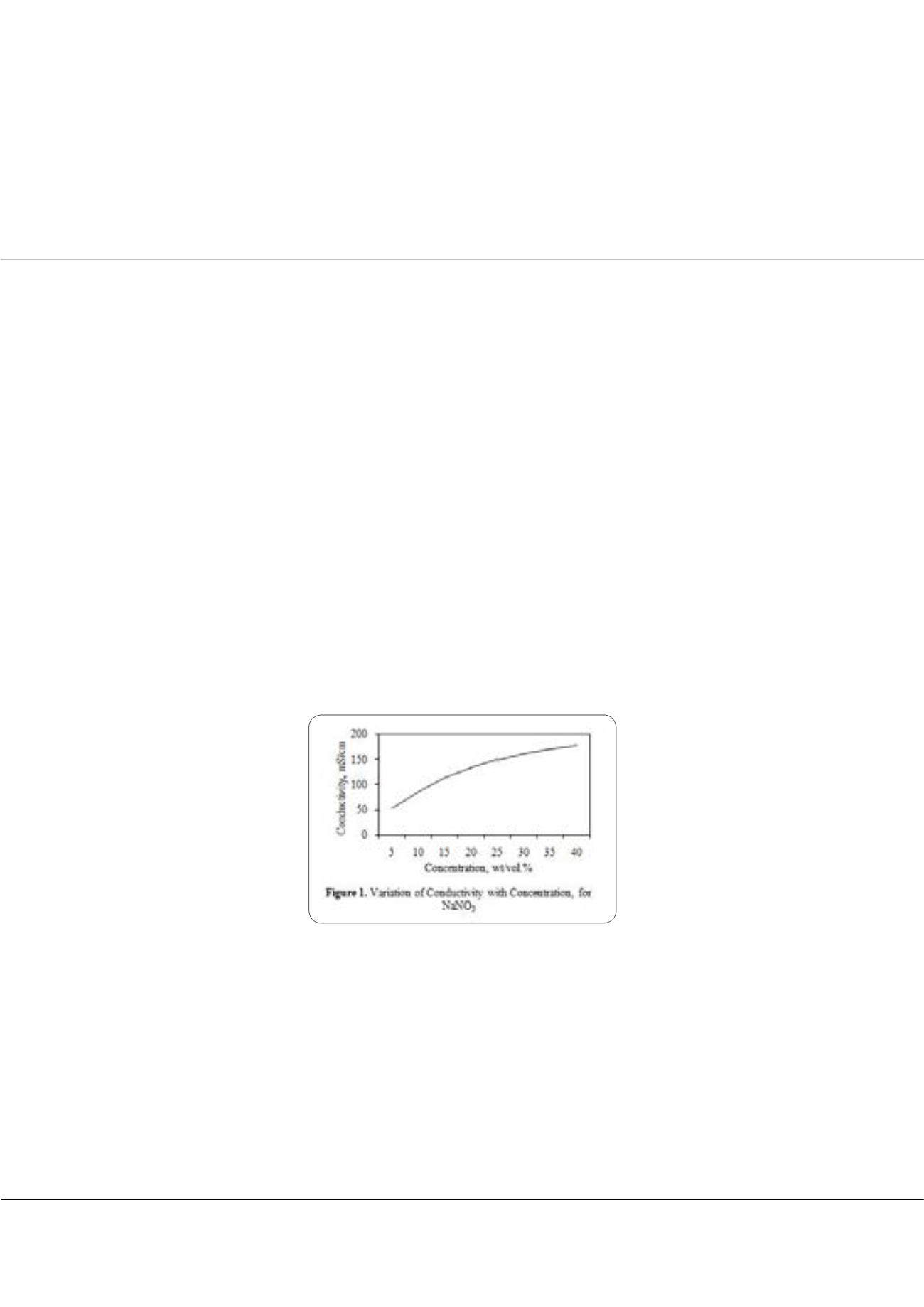

Methodology & Theoretical Orientation:

Sample testing solutions were prepared in laboratory for the electrolytes, sodium

chloride and sodium nitrate. Conductivity and total dissolved solids (TDS) measurements were taken for each sample and

recorded. Standard conductivity and TDS versus concentration charts were prepared corresponding to the measurements.

Then the charts are trend-fitted to obtain certain empirical relations for the concerned parameters. These relations are then

used to identify the value of conductivity by substituting the desired amount of concentration.

Conclusion & Significance:

The measured values of conductivity and TDS for various concentrations of sodium chloride and

sodium nitrate show a proportionate growth with respect to the concentrations. The interpolation models obtained from the

plots can be utilized in industrial ECD operations to control and manipulate concentration of electrolytes. As it is a difficult task

to maintain a set value of concentration in such applications, this technique can simplify it by monitoring the corresponding

value of conductivity for the required concentration.

Recent Publications:

1.

B Bhattacharyya and J Munda (2003) Experimental investigation on the influence of electrochemical machining

parameters on machining rate and accuracy in micromachining domain. International Journal of Machine Tools &

Manufacture 43:1301–1310.

2.

B Bhattacharyya, J Munda and M Malapati (2004) Advancement in electrochemical micro-machining. International

Journal of Machine Tools & Manufacture 44:1577–1589.

3.

K P Rajurkar, D Zhu, J A McGeough, J Kozak and A De Silva (1999) New Developments in Electro-Chemical Machining.

CIRP Annals 48(2):567-579.

4.

Atkins P W and de Paula J (2006) Physical Chemistry (8th ed.), Oxford University Press, ISBN 0198700725.

5.

S K Sorkhel and B Bhattacharyya (1994) Parametric control for optimal quality of the workpiece surface in ECM. Journal

of Materials Processing Technology 40:271-286 271

Alay Patel et al., Biosens J 2018, Volume 7

DOI: 10.4172/2090-4967-C1-002