Page 97

conferenceseries

.com

Volume 8

Journal of Biotechnology and Biomaterials

ISSN: 2155-952X

Biomaterials 2018

March 05-06, 2018

March 05-06, 2018 | Berlin, Germany

3

rd

Annual Conference and Expo on

Biomaterials

Fabrication of calcium sulfate hemihydrate coated β-tricalcium phosphate through dissolution

precipitation reaction

Eddy Eddy, Akira Tsuchiya, Kanji Tsuru

and

Kunio Ishikawa

Kyushu University, Japan

Introduction:

Previously, we had proposed that beta tricalcium phosphate granular cement (β-TCPGC) is useful to prevent

flowing out of the β-TCP granules from the bone defect. When the β-TCP granules were mixed with acidic calcium phosphate

solution, it set to form interconnected porous structure. Although it seems promising, β-TCP granules need to be mixed with

the acidic calcium phosphate solution. Calcium sulfate hemihydrate (CSH) has self-setting ability by converting to calcium

sulfate dihydrate (CSD) when exposed to water. Furthermore, CSD is the component of Osteoset®, which is a commercially

available as a bone substitute. In this study, we fabricated CSH coated β-TCP granules through dissolution-precipitation

method. This setting ability could inhibit the flowing out of the β-TCP granules from the bone defect.

Experimental Method:

β-TCP granules were immersed in NaHSO4 solution for 1, 3, 5 and 7 days at 70

o

C. The samples

were then heated at 120

o

C for 4 hours. β-TCPGC was prepared by mixing the granules with saline solution at a L/P ratio of

0:3 and identified by XRD and SEM. The mechanical strength of the β-TCPGC was measured as a DTS by universal testing

machine. β-TCPGC was implanted in rabbit femur for 4 weeks and the percentage of newly formed bone was calculated from

histological analysis.

Results:

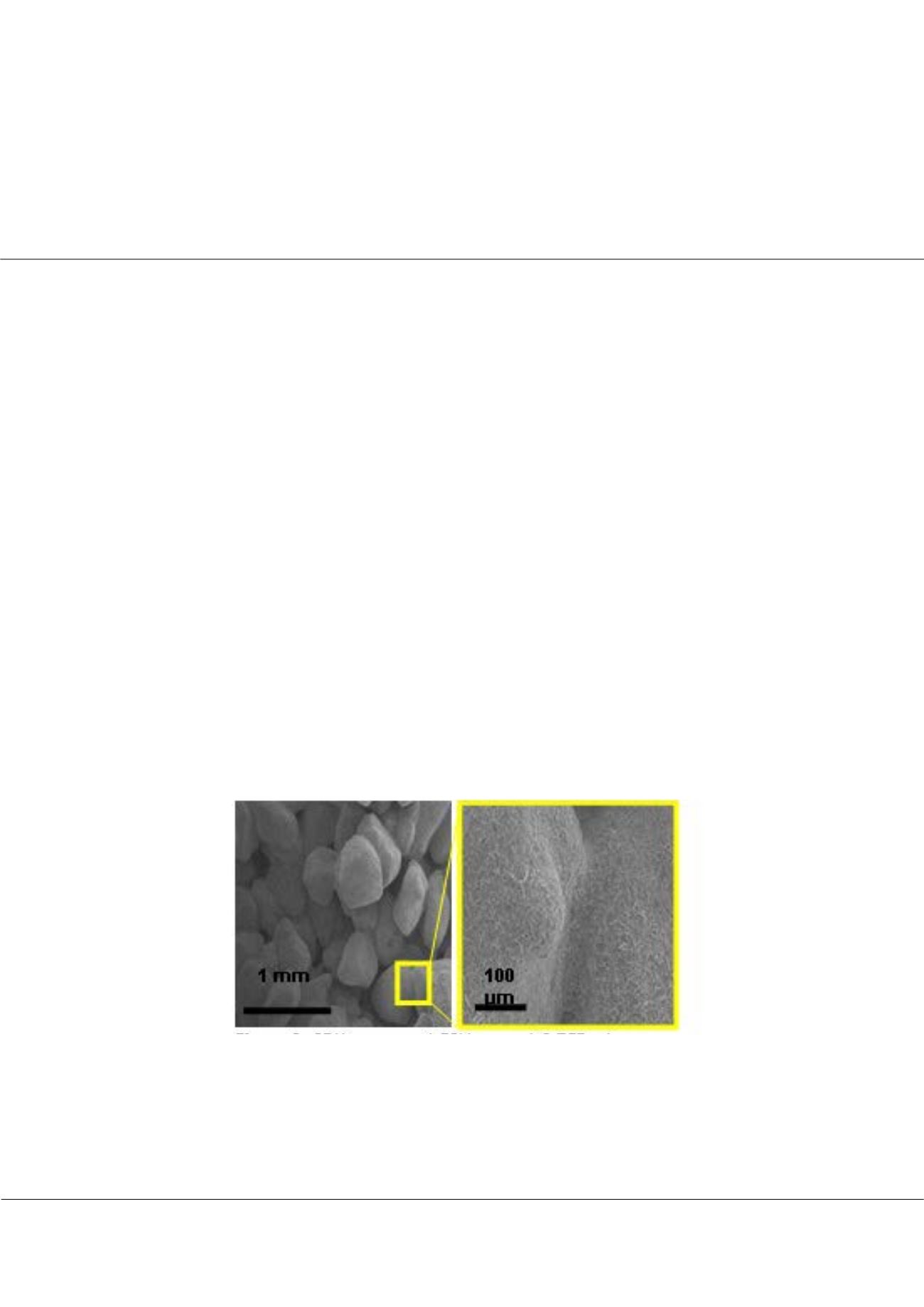

β-TCP granules immersed in NaHSO4 solution were coated by CSD and CSD became CSH after heating at 120ºC for

4 hours. CSH coated β-TCP granules mixed with saline solution were set and DTS value of β-TCPGC with 75 wt.% of CSH

was 0.8±0.1 MPa. The percentage of newly formed bone of β-TCPGC with 75 wt.% of CSH was 28.7±0.5%. Meanwhile, β-TCP

granules without coating were 19.9±1.1%.

Conclusion:

CSH coated β-TCP were successfully fabricated and formed interconnected porous structure with good

mechanical strength after mixing with saline solution

Figure 1: SEM images of CSH coated β-TCP after mixed with saline solution and formed interconnected porous structure.

Recent publications

1. Fukuda N, Tsuru K, Mori Y and Ishikawa K (2017) Fabrication of self-setting β-tricalcium phosphate granular cement. J

Biomed Mater Res: Part B-App Biomater. 106(2):800-807.

2. Fukuda N, Tsuru K, Mori Y and Ishikawa K (2017) Effect of citric acid on setting reaction and tissue response to β-TCP

granular cement. Biomed Mater. 12(1):15027.

Eddy Eddy et al., J Biotechnol Biomater 2018, Volume 8

DOI: 10.4172/2155-952X-C1-088