Page 94

conferenceseries

.com

Volume 8

Journal of Biotechnology and Biomaterials

ISSN: 2155-952X

Biomaterials 2018

March 05-06, 2018

March 05-06, 2018 | Berlin, Germany

3

rd

Annual Conference and Expo on

Biomaterials

Multi-layer PVD coatings for longer lasting orthopaedic implants: A tribocorrosion evaluation

Raisa Chetcuti

1

, Joseph Buhagiar

1

, Peter A Dearnley

2

and

Bertram Mallia1

1

University of Malta, Malta

2

Boride Services Ltd, United Kingdom

B

one injuries coupled with a longer life expectancy necessitate the increased longevity of implanted biomaterials in patients

suffering from bone diseases such as arthritis and osteoporosis. CoCrMo alloys have been widely employed as bearing

surfaces in metal-on-metal (MoM) orthopaedic implants given their optimal mechanical properties and high corrosion

resistance, as well as their relatively low wear rates and the post-operative stability. Loss of material by corrosion-wear of the hip

joint and metal ion release into the blood stream are of prime concern as these can cause adverse reactions in the human body

such as inflammation and bone erosion as well as loosening of the implant. This study aims to reduce the material loss at the

bearing surfaces by the application of a multi-layer PVD coating on an ASTM F-1537 CoCrMo substrate. A 2.3 µm thick CrN

coating was deposited on top of a 3.6 µm CoCrMo precipitate free supersaturated metastable solution of carbon, otherwise

known as S-phase (S), by magnetron sputtered PVD. The coated samples designated as CrN/S, displayed a higher hardness and

they retained their topography in nano-scratch tests relative to the uncoated CoCrMo substrate under the same conditions.

Tribocorrosion tests for uncoated CoCrMo samples against uncoated CoCrMo counterfaces as well as for coated samples

against coated counterfaces were conducted in Ringer’s solution as well as in diluted Foetal calf bovine serum at 37±1 °C under

reciprocating sliding conditions. Results show that under all applied potentials and in both solutions, the coated tribopairs

when compared to the uncoated ones exhibited a significant decrease in material loss and excellent resistance to catastrophic

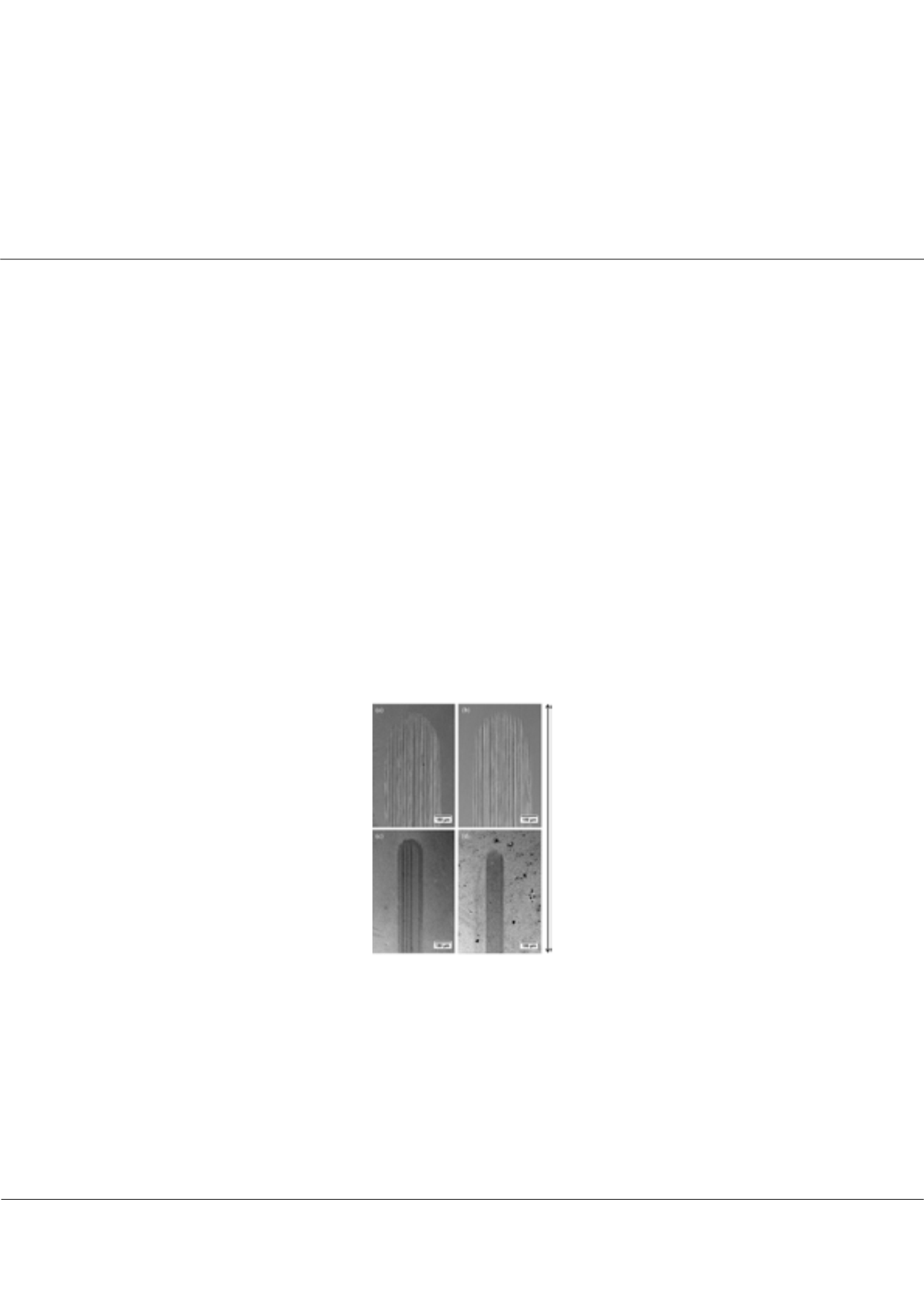

failure by tribocorrosion. Figure 1 outlines the improvement exhibited by the coated samples under anodic conditions; the

coated samples exhibiting a smaller wear scar and mostly polishing wear as opposed to the uncoated samples, in both solutions.

Figure 1: SEM images of the scars of (a, b) uncoated ASTM F-1537 CoCrMo samples against an uncoated ASTM F-1537 CoCrMo counterface in Ringer’s solution and

diluted Foetal calf bovine serum respectively, (c, d) CrN/S coated ASTM F-1537 CoCrMo samples against a CrN/S coated ASTM F-1537 CoCrMo counterface in Ringer’s

solution and Foetal calf bovine serum respectively, following sliding under anodic conditions. The arrow indicates the direction of sliding during tribocorrosion testing

Biography

Raisa Chetcuti earned a B.Eng (Hons.) degree in Mechanical Engineering from the University of Malta in 2016. She is currently reading for an MSc in Mechanical

Engineering at the same institution. Her research interests lie in the general field of biomaterials, but in her study, she is focusing on the tribocorrosion behaviour

of PVD coatings to be applied to the artificial hip joint in conditions which replicate more closely the human body environment. In 2016, she has studied two novel

PVD coatings for the bearings of the artificial hip joint and she was acknowledged with the best project in the mechanical engineering stream for 2016 award by

the Chamber of Engineers in Malta.

raisa.chetcuti.12@um.edu.mtRaisa Chetcuti et al., J Biotechnol Biomater 2018, Volume 8

DOI: 10.4172/2155-952X-C1-088