Page 111

conferenceseries

.com

Volume 9

Journal of Bioremediation & Biodegradation

ISSN: 2155-6199

Biofuel Congress 2018 &

Biomass 2018

September 04-06, 2018

JOINT EVENT

September 04-06, 2018 | Zurich, Switzerland

13

th

Global Summit and Expo on

Biomass and Bioenergy

&

12

th

World Congress on

Biofuels and Bioenergy

Mechanochemistry for a smart and sustainable biodiesel production under heterogeneous catalysis

Irene Malpartida

1

, Pedro J. Maireles

1

, Valentin Lair

2

, Samy Halloumi

2

, Julien Thyel

2

and

FranÇois Lacoste

2

1

University of Malaga, Spain,

2

Deasyl S.L., Geneva, Switzerland

F

atty acid methyl esters (FAME) produced from vegetable oil by transesterification, labeled as ‘‘Biodiesel”, is industrially

accomplished in the presence of a homogeneous basic catalyst, such as alkali hydroxide or methoxide dissolved in

methanol. This process requires a large excess of methanol (methanol:oil molar ratio> 6), temperature around 60 ºC and 1-2 h

of reaction [1]. However, this process suffers from important drawbacks: low FFA and water tolerance, generation of process

wastewater, etc. To overcome them, different approaches have been proposed: such as the use of heterogeneous catalysis, CO2

under supercritical conditions or enzymes; coupled to microwave and ultrasonics systems as an alternative to conventional

heating [2-3]. Among all the researches, heterogeneous catalysts show potential in the transesterification reaction. Unlike

homogeneous catalysts, heterogeneous ones are environmentally benign and can be reused and regenerated. Nevertheless,

higher catalyst loading and alcohol:oil molar ratio are required for biodiesel production in the presence of solid catalysts [4].

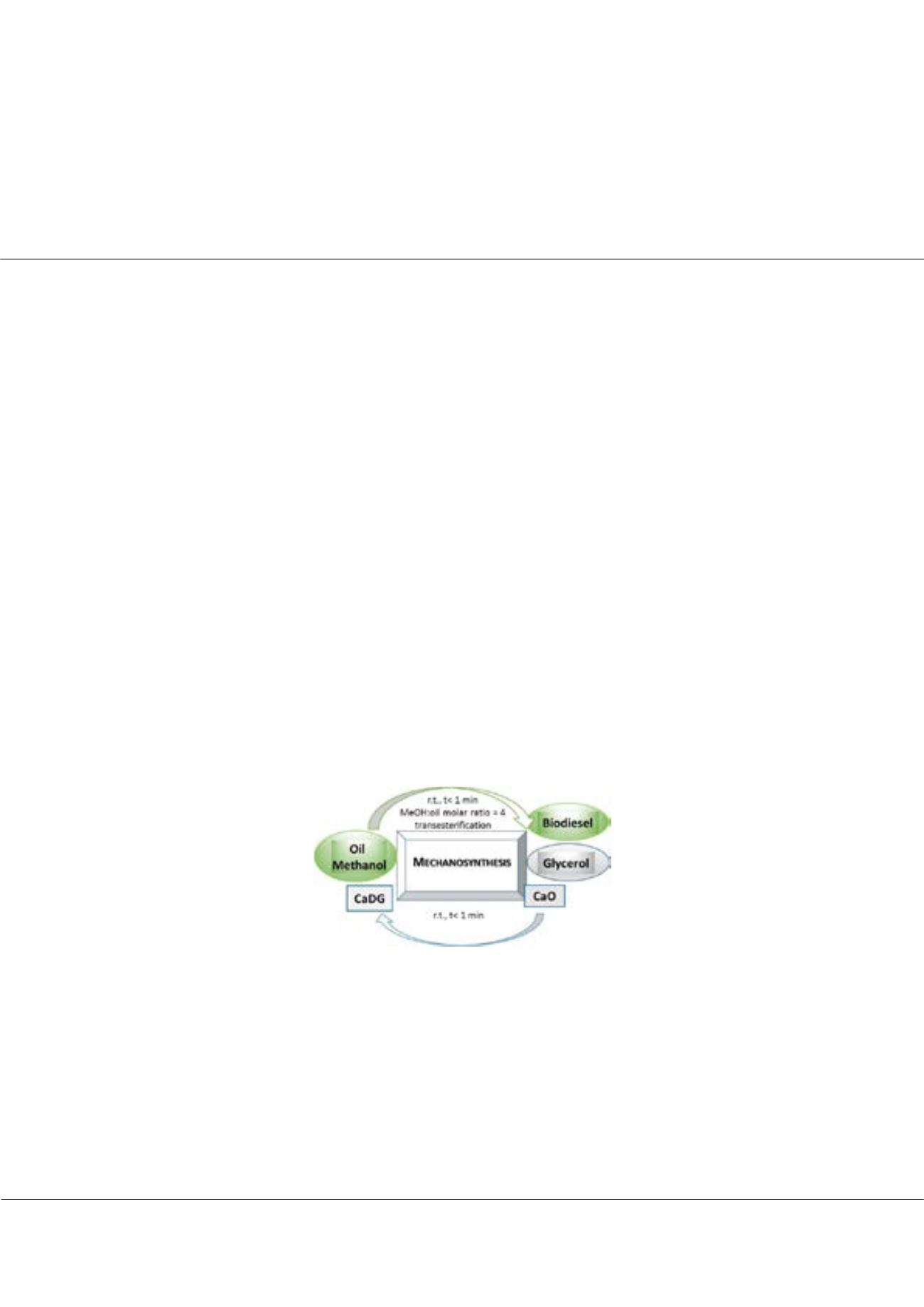

Methodology & Results:

A new mechanochemical reactor is used for the transesterification reaction to promotes the reactants

mixing, minimizing mass transfer limitations associated to the inmiscibility of reactants. This solution allows to reduce the

methanol need to an amount close to the stoichiometry (methanol:oil molar ratio= 4:1), and at room temperature after less

than one minute, more than 90 wt% FAME is reached [5].

Findings:

Glycerol, obtained as by-product in the transesterification reaction is used to prepare calcium diglyceroxide by

mechanosynthesis, and is used as heterogeneous catalyst. A new and more efficient mechanochemical synthesis of FAME is

proposed, with shorter reaction and lower temperature [6], compared to other synthesis proposed in literature [7].

Significance:

A new, smart and efficient process for biodiesel production was developed, without waste generation (no

water, nearly no excess of methanol), with valorization of glycerol for catalyst synthesis, under very low energy consumption

conditions.

Recent Publications

1. B. Freedman, E.H. Pryde, T.L. Mounts, Variables affecting the yield of fatty esters from transesterified vegetable oil, JAOCS

61 (1984) 1638–1643.

2. Juan Miguel Rubio-Caballero, Jose Santamarıa-Gonzalez, Josefa Merida-Robles, Ramon Moreno-Tost, Antonio Jimenez-

Lopez, Pedro Maireles-Torres, Applied Catalysis B: Environmental 91 (2009) 339–346.

3. Ana C. Alba-Rubio, Jose Santamarıa-Gonzalez, Josefa M. Me rida-Robles, Ramon Moreno-Tost, David Martın-Alonso,

Antonio Jimenez-Lopez, Pedro Maireles-Torres, Catalysis Today 149 (2010) 281–287

4. Ferenc E. Kiss, Milenko Jovanovi, Goran C. Bošković, Fuel Processing Technology 91 (2010) 1316–1320

5. Patent new biodiesel process - WO2018002559: Method for producing fatty acid esters and glycerol at low temperature.

Irene Malpartida et al., J Bioremediat Biodegrad 2018, Volume 9

DOI: 10.4172/2155-6199-C1-01

5