Page 56

conferenceseries

.com

Volume 7

Innovative Energy & Research

ISSN: 2576-1463

Advanced Energy Materials 2018

August 13-14, 2018

August 13-14, 2018 | Dublin, Ireland

20

th

International Conference on

Advanced Energy Materials and Research

Materials for thermochemical energy storage: Experimental investigation of cycling stability

M. Gollsch, J. Stengler, M. Spindler

and

M. Linder

Institute of Engineering Thermodynamics,German Aerospace Center (DLR), Germany

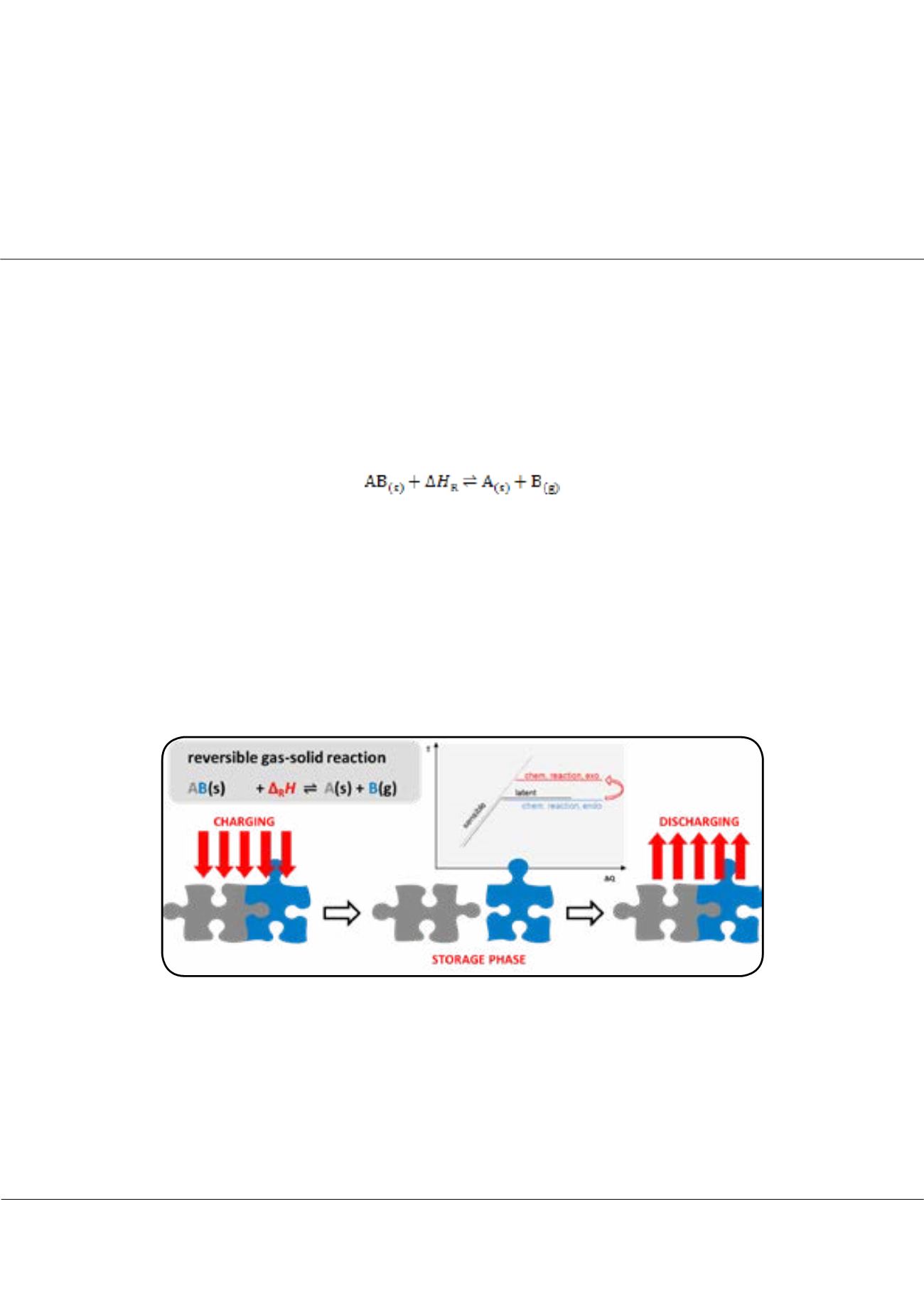

T

hermochemical energy storage (TCS) uses the reaction enthalpy of reversible chemical reactions. This storage technology

contains a so far largely untouched potential: in comparison to sensible and latent thermal energy storage, TCS offers

potentially higher storage densities, the possibility of long-term storage as well as the option to upgrade the thermal energy.

This upgrade can be realised if the reaction system consists of a solid and a gaseous component. For these gas-solid reactions

with the generic equation

the equilibrium temperature is dependent on the reaction gas partial pressure: the higher the partial pressure, the higher the

reaction temperature. Consequently, the charging of the storage can take place at lower temperatures than the discharging

by adjustment of the reaction gas partial pressure. Currently, a number of water vapour-solid reactions are investigated as

thermochemical storage materials [1-4]. Apart from a general suitability of a reaction system for thermochemical storage,

special attention has to be paid to the cycling stability of the reaction. This is often done using thermogravimetric analysis [5].

However, past scale-ups have shown that behaviour of bulks differs from that of analysis amounts [6]. The bulk’s changing

properties, however, have proven to be crucial for storage reactor design. The investigation of the cycling stability and reaction

behaviour of reacting solid bulks has been our motivation to design and build a cycling test bench. In this experimental

setup the gaseous reaction partner is water vapour and can be provided at pressures between 5 kPa and 0.5 MPa. Reactor

temperatures can be up to 500 °C. The aim of the presented studies is the automated cycling of about 100 ml solid storage

material of reaction systems that have previously shown promise at analysis scale.

Recent Publications

1. Gutierrez, A., Ushak, S., Linder, M. (2018) High Carnallite-Bearing Material for Thermochemical Energy Storage:

Thermophysical Characterization. ACS Sustainable Chemistry and Engineering 6(5):6135-6145

2. Afflerbach, S., Kowald, T., Trettin, R. (2017) Phase transformations during de- and rehydration of scholzite

CaZn

2

(PO

4

)

2

•2H

2

O. Journal of Solid State Chemistry 254:184-194

3. Stengler, J., Ascher, T., Linder, M. (2017) High temperature thermochemical heat transformation based on SrBr

2

. 12th

IEA Heat Pump Conference, 15th-18th May, 2017, Rotterdam

M. Gollsch et al., Innov Ener Res 2018, Volume 7

DOI: 10.4172/2576-1463-C1-002