Page 90

conferenceseries

.com

Volume 7

Innovative Energy & Research

ISSN: 2576-1463

Advanced Energy Materials 2018

August 13-14, 2018

August 13-14, 2018 | Dublin, Ireland

20

th

International Conference on

Advanced Energy Materials and Research

New approach for local treatment of defects on glazed ceramics by CO

2

laser

N M Ferreira

1

, J M Fernandes

1

, C M S Freitas

1

, F Rey García

1

, J Carneiro

2

, M N Capela

2

, R Santos

3

, A J S Fernandes

1

, M P Seabra

2

and

F M Costa

1

1

University of Aveiro, Portugal

2

CICECO – Aveiro Institute of Materials, Portugal

3

Coimbra iParque - Parque tecnológico de Coimbra, Portugal

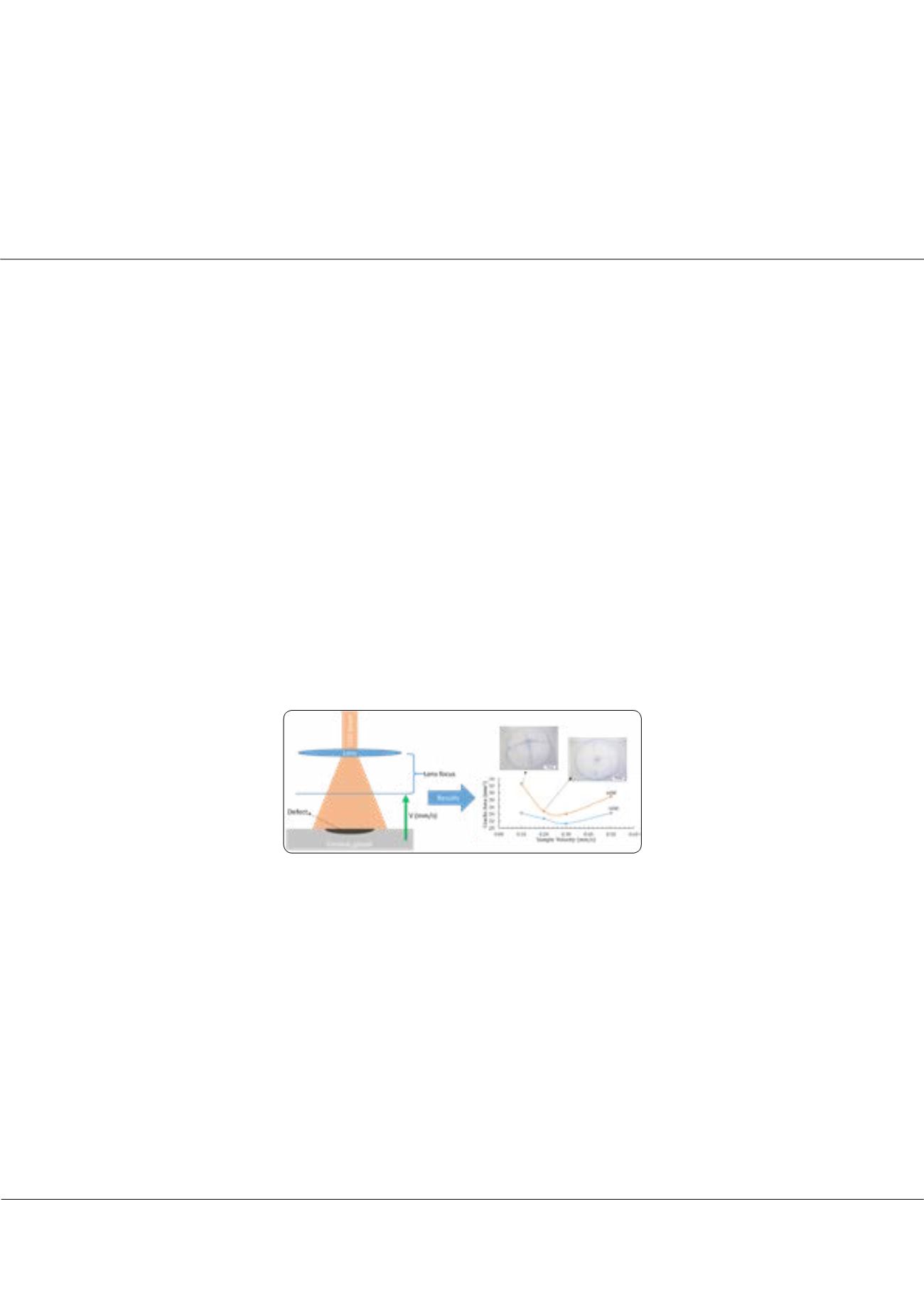

T

he evolution on ceramic industry is constant and significant improvements in automation and process efficiency are

necessary. The treatment of small defects usually involves a new firing to repair small defects with only a few mm

2

,

representing a significant increase in costs productions. One option is the use of laser technology to in situ repair defects

of the ceramic pieces, preventing all the extra costs associated with a re-firing. Several authors indicating that CO

2

laser is

strongly absorbed by the ceramic material, allowing the repairs in a rapid and highly localized manner. This study present a

new approach of using a CO

2

laser to repair small defects on the surface of ceramics glazed. The application of laser technology

to the traditional repairing material proved problematic since it was detected the formation of microcracks ascribed to

thermal stresses generated by the high temperature gradients. To overcome this, alternative approaches through changing the

interaction area of the laser beam on the piece to repair, in order to reduce the thermal stresses due to the heat by laser beam.

Repaired defects were evaluated based on the velocity of the piece motion to laser focus, power of the laser, presence of cracks

on the surface and the size of microscopic cracks. The incident laser power, duration of laser heating/cooling and velocity of

approach were analysed. After laser treatment the restored surfaces and cross sections were analysed by μ-Raman spectroscopy,

3D optical profilometry and optical microscopy together with optical and chemical/mechanical characterization. The results

show the effect of velocity and power laser of the spread of cracks and microcracks on the surface of material irradiated.

Nevertheless, this new approaches show good results to implement laser technology in the repair of ceramic industry.

Recent Publications:

1. K. Osvay, I. Képíró, and O. Berkesi, “Laser treatment of white China surface,” Appl. Surf. Sci., 2006.

2. S. Rodríguez-López, R. Comesaña, J. del Val, A. Durán, V. M. Justo, F. C. Serbena, and M. J. Pascual, “Laser cladding

of glass-ceramic sealants for SOFC,” J. Eur. Ceram. Soc., vol. 35, no. 16, pp. 4475–4484, Dec. 2015.

3. N. B. Dahotre and S. P. Harimkar, Laser Fabrication and Machining of Materials. Springer, 2008.

4. J. D. Majumdar and I. Manna, Laser-Assisted Fabrication of Materials. 2012.

5. X. Li, J. Wang, L. L. Shaw, and T. B. Cameron, “Laser densification of extruded dental porcelain bodies in multi-

material laser densification process,” Rapid Prototyp. J., vol. 11, no. 1, pp. 52–58, 2005.

6. N. Basile, M. Gonon, F. Petit, and F. Cambier, “Processing of a glass ceramic surface by selective focused beam laser

treatment,” Ceram. Int., 2016.

7. D. Triantafyllidis, L. Li, and F. H. Stott, “Crack-free densification of ceramics by laser surface treatment,” Surf. Coatings

Technol., 2006.

N M Ferreira et al., Innov Ener Res 2018, Volume 7

DOI: 10.4172/2576-1463-C1-003