Page 86

conferenceseries

.com

Volume 7

Innovative Energy & Research

ISSN: 2576-1463

Advanced Energy Materials 2018

August 13-14, 2018

August 13-14, 2018 | Dublin, Ireland

20

th

International Conference on

Advanced Energy Materials and Research

Asymmetric rolling of polycrystalline metals: Modification of microstructure and mechanical

properties

A. Uniwersał

1

, S. Wroński

1

, K. Wierzbanowski

1

, M. Wróbel

1

, M. Wroński

1

and

B Bacroix

2

1

AGH University of Science and Technology, Poland

2

LSPM-CNRS, Université Paris 13, France

A

symmetric rolling process is a subject of many research works in the last years. In this kind of rolling some technological

parameters can be modified, like: normal force and torque, sample shape (by bending) and power requirements. The

material properties are also noticeably modified. An important shear deformation, characteristic for this process, leads

to texture rotation, microstructure refinement and increase of material strength. Asymmetric rolling can be realized by a

modification of existing rolling mills, therefore its industrial application is possible at a relatively low cost. The aimof the present

study was to characterize this process and resulting material modifications of face centered cubic (fcc) and hexagonal close

packed (hcp) metals: aluminum, copper and titanium. The cases of low and high deformations were examined. The electron

backscatter diffraction (EBSD), X-ray diffraction (XRD), calorimetry and microhardness measurements were performed.

Texture and mechanical characteristics were studied using a crystal deformation model and finite element method (FEM). The

following material and process modifications were found as a result of asymmetric rolling: sample bending, which can be partly

controlled; decrease of mill load and an increase of the average rolling torque; increase of microhardness mechanical strength;

increase of energy released during recrystallization; texture rotation around transverse direction; decrease of the average grains

size (persisting in some extent also after recrystallization) and formation of more fragmented grains and; modification of lattice

misorientation distributions.

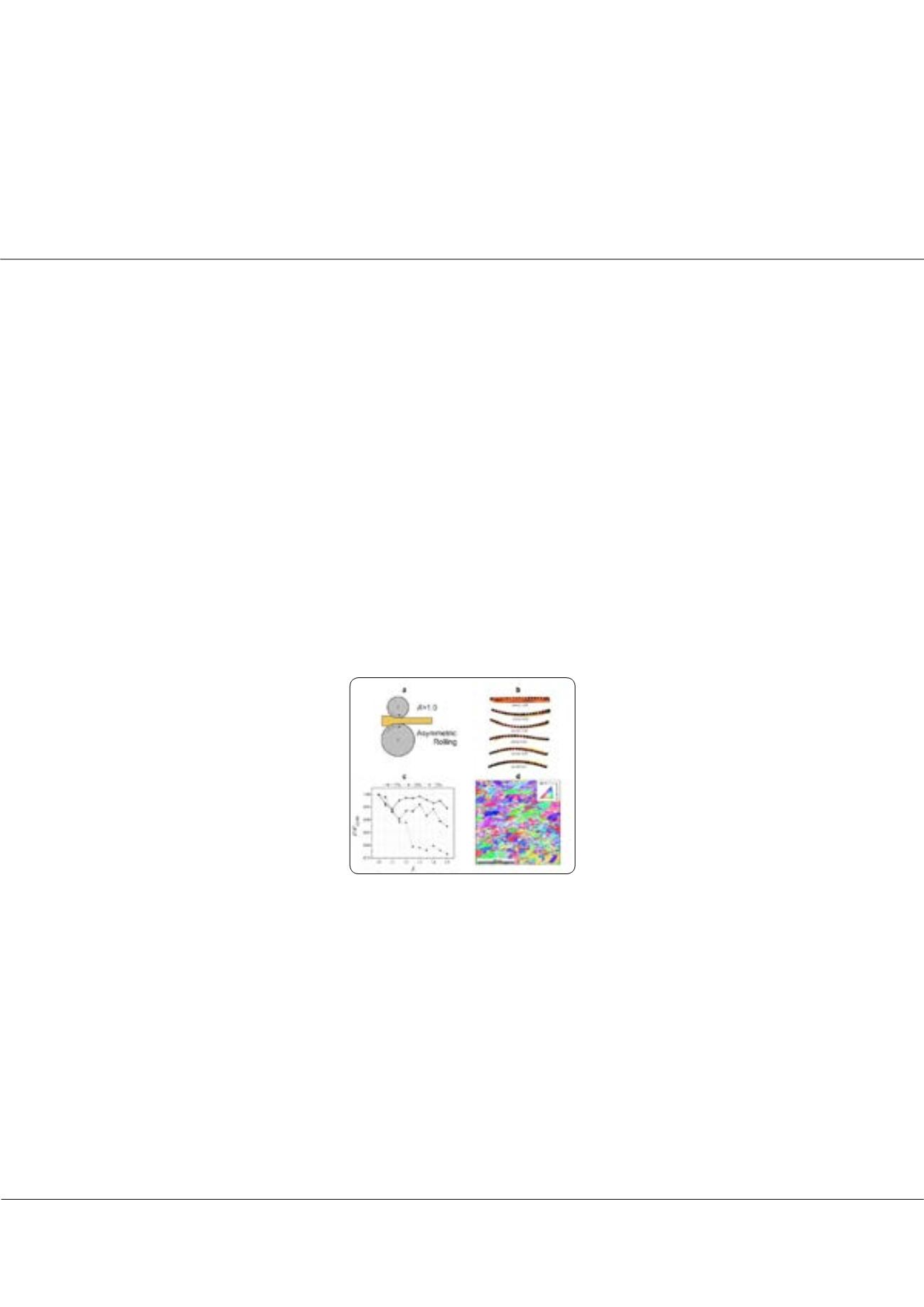

Fig.1. a)

geometry of asymmetric rolling,

b)

shape of asymmetrically rolled sheets vs. asymmetry ratio

A, c)

reduction of normal rolling force vs.

A, d)

microstructure of asymmetrically rolled copper sample.

Recent Publications:

1. J. Jiang, Y. Ding, F. Zuo, A. Shan (2009) Mechanical properties andmicrostructures of ultrafine-grained pure aluminum

by asymmetric rolling, Scripta Mater., 60:905–908

2. J. Liu, R. Kawalla (2012), Influence of asymmetric hot rolling on microstructure and rolling force with austenitic steel,

T. Nonfer. Metal Soc., 22:388-391

3. S. Wronski, B. Ghilianu, T. Chauveau , B. Bacroix (2011), Analysis of textures heterogeneity in cold and warm

asymmetrically rolled aluminium, Mater. Charact., 62:22-34

4. A. Uniwersał, M.Wróbel, K. Wierzbanowski, S. Wroński, M. Wroński, I. Kalemba-Rec, T. Sak, B. Bacroix (2016)

Microstructure, texture and mechanical characteristics of asymmetrically rolled polycrystalline copper, Mater.

Charact. 118:575–583

5. M. Wroński, K. Wierzbanowski, M. Wrobel, S. Wronski, B. Bacroix (2015) The effect of rolling asymmetry on selected

properties of grade 2 titanium sheet, Met. Mater.-Int., 21 (2015) 805-814.

K. Wierzbanowski et al., Innov Ener Res 2018, Volume 7

DOI: 10.4172/2576-1463-C1-003