Page 72

conferenceseries

.com

Volume 9

International Journal of Advancements in Technology

ISSN: 0976-4860

3D Printing 2018

March 19-20, 2018

March 19-20, 2018 | London, UK

2

nd

International Conference on

3D Printing Technology and Innovations

Investigation on the effect of processing parameters on 3D printed structures

Chao Zhu, Chamil Akeykoon

and

Anura Fernando

University of Manchester, UK

T

he Fused Deposition Modelling (FDM), which is one of the main additive manufacturing technologies, is widely used

in many fields with multiple materials. Additive manufacturing shows a rapid development over the last decade and

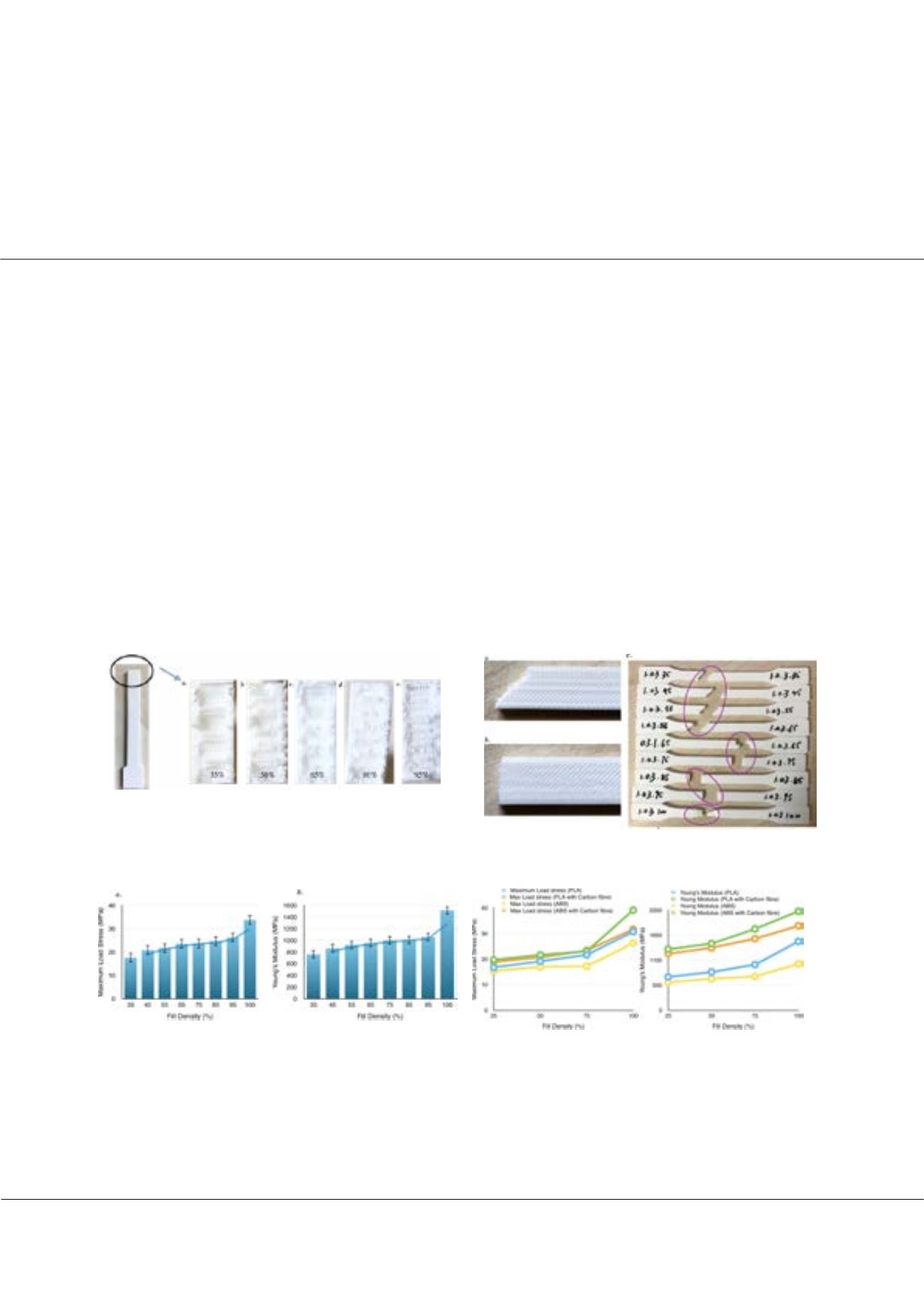

hence FDM printing machines have been improved remarkably. In this work, the effects of several set parameters on 3D

printed samples’ mechanical properties and their printing quality were explored. It seems that the fill density affects samples’

mechanical properties significantly and the variation of maximum load stress and the Young’s modulus changed linearly

with increased density. Moreover, the fill pattern affects fiber’s structure and determines the products’ structural properties.

The mechanical properties of samples and the printing time were also affected significantly with different layer thicknesses.

Samples with different fill patterns showed highly varying properties; e.g. samples with linear fill pattern showed the best

tensile properties where samples with “diamond” fill pattern can have a large deformation during tests. Furthermore, the effects

of different materials (e.g. PLA (Poly Lactic Acid), ABS (Acylonitrile Butadiene Styrene), carbon fibre reinforced PLA/ABS) on

the properties 3D printed structures were also observed and the results showed that the samples with both carbon reinforced

PLA and ABS are better in tensile properties than pure PLA and ABS. However, they were found to be more brittle in nature.

Moreover, the samples printed from carbon fibre reinforced materials showed a 45-55% increase in tensile properties and a

40-55% increase in Young’s modulus compared to pure PLA and ABS.

Biography

Chao Zhu graduated with a Bachelor’s Degree from Northwestern Polytechnical University, Xian, People’s Republic of China. He will get a M Eng Degree from The

University of Manchester next year. His interest lies in manufacturing especially in 3D Printing Future Technology.

chao.zhu-3@student.manchester.ac.ukChao Zhu et al., Int J Adv Technol 2018, Volume 9

DOI: 10.4172/0976-4860-C1-002

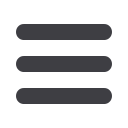

Figure 1:

Fracture surface of samples: fill density

(a).35%, (b).50%, (c).65%, (d).80%, (e).95%.

Figure 3:

The variation of maximum load stress

and the Young’s modulus with fill density.

Figure 4:

Maximum load stress and Young’s modulus of

carbon reinforced polymer and pure PLA and ABS.

Figure 2:

Changes to the fracture plane with fill density.