Page 85

conferenceseries

.com

Volume 8

Journal of Biotechnology and Biomaterials

ISSN: 2155-952X

Biomaterials 2018

March 05-06, 2018

March 05-06, 2018 | Berlin, Germany

3

rd

Annual Conference and Expo on

Biomaterials

Biomimetic gelatine coating for less-biodegradable and surface bioactive Mg alloys

Vanja Kokol

1

, Hanuma Reddy Tiyyagura

1,2

, Barbara Petovar

1

, Matjaž Finšgar1, Regine Willumeit-Römer

3

, Bérengère J C Luthringer

3

, Mantravadi Krishna

Mohan

2

1

University of Maribor, Slovenia

2

Institute of Technology-Warangal, India

3

Institute of Material Research, Germany

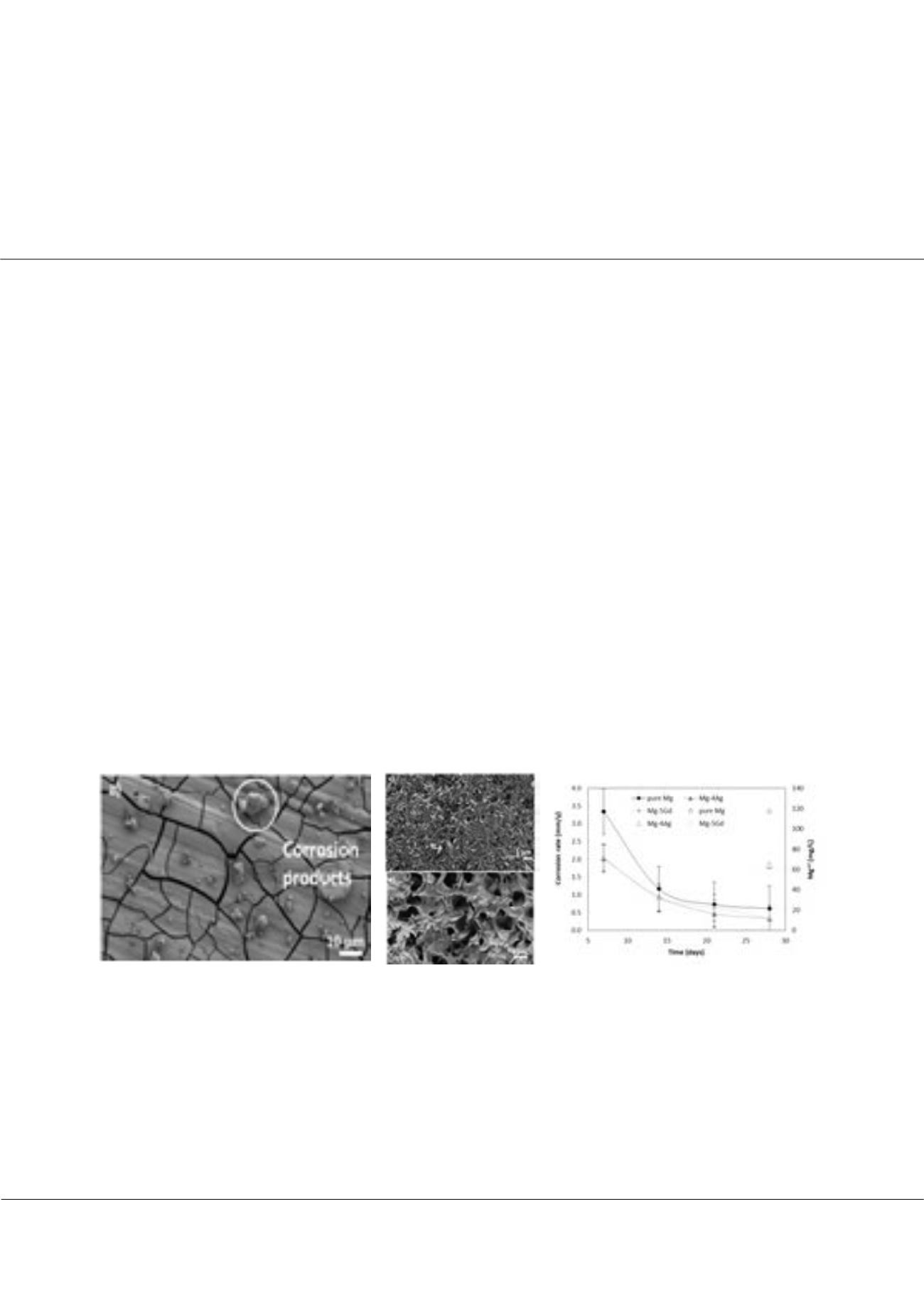

M

agnesium (Mg) alloys have emerged as innovative orthopaedic implant materials due to their excellent degradability,

which eliminates the need for a second surgery for their removal. However, rapid degradation of Mg alloys and subsequent

loss of mechanical integrity before the tissue regeneration limits their application. The Mg-4Ag and Mg-5Gd binary alloys`

degradation and corrosion properties were studied under

in vitro

conditions (in a simulated body fluid solution of pH 7.4 at

37°C) by using various analytical techniques and time-frame windows (up to 3 vs. 28 days), and compared with the pure (99.9

wt%) Mg alloy, before and after a biomimetic gelatin (GEL) coating via dopamine. Different kinetics and mechanisms of the

alloys` degradation were identified, influencing their corrosion rates` dynamics. The EIS measurements of uncoated alloys,

being performed for up to 3 days, revealed that the corrosion of all three alloys are under a kinetic-controlled mechanism,

among which only pure Mg and Mg-4Ag show a repassivation ability in this time-frame. However, the corrosion rates of binary

alloys were lower, reaching a value of around 0.33 mm/y and a release of 64 mg/L Mg

2+

ions after 28 days of incubation, that

was accompanied by a lower pH change (up to pH 8.3), compared to the pure Mg alloy, getting additionally reduced by GEL

coating. The spectroscopic (FTIR, XRD, EDXS) and microscopic (SEM) studies revealed the formation of MgO products, as

well as apatite formation on the pure Mg alloy surface, while thick and homogenous layers of differently-shaped and chemically

secondary-phased Mg(OH)

2

products were identified on both binary alloys after 28 days. Besides, a protective interface layer

between the alloy surface and SBF solution was formed on GEL-coated alloys, which further stimulates the mineralization of

calcium phosphate compounds, being patterned by GEL macromolecules conformation. Among the binary alloys tested, the

Mg-4Ag alloy seems to be the most appropriate biomaterial regarding the in-vitro degradation process that would lead to a

suitable healing process at the implantation site, compared to the others available from the literature.

SEM images of (a) pure Mg, (c) Mg-4Ag and (e) Mg-5Gd alloys` surface with corresponding corrosion rates and Mg

2+

ions release, after 28 days of immersion in SBF at 37±0.5˚C.

Recent publications

1. Tiyyagura HR, Gorgieva S, Fuchs-Godec R, MohanMK and Kokol V Biomimetic gelatine coating for less-corrosive and

surface bioactive AZ91 Mg alloy. J. Mater. Res. submitted revision JMR-2017-0979.

2. Tiyyagura H R, Rudolf R, Gorgieva S, Fuchs-Godec R, Venkatappa Rao B, et al. (2016) The chitosan coating and

processing effect on the physiological corrosion behaviour of porous magnesium monoliths. Progress in Organic

Coatings 99(4):147-156.

Vanja Kokol et al., J Biotechnol Biomater 2018, Volume 8

DOI: 10.4172/2155-952X-C1-088