Page 70

conferenceseries

.com

Volume 8

Journal of Biotechnology and Biomaterials

ISSN: 2155-952X

Biomaterials 2018

March 05-06, 2018

March 05-06, 2018 | Berlin, Germany

3

rd

Annual Conference and Expo on

Biomaterials

Fabrication of porous materials

Peng-Sheng Wei

National Sun Yat-Sen University, Taiwan

T

he shape of a pore, resulting from a bubble entrapped by a solidification front, is predicted in this work. Porosity influences not

only microstructure of materials, but also contemporary issues of various sciences of biology, engineering, foods, geophysics

and climate change, etc. In this presentation, pore shape is determined by accounting for mass and momentum transport of solute

across a self-consistent shape of the cap, as proposed previously. This work finds that there exist three different mechanisms for pore

formation, depending on different directions and magnitude of solute transfer across the cap. Case 1 is subject to solute transport

from the pore into surrounding liquid as a result of the cap emerged from a thin concentration boundary layer on the solidification

front in the early stage. An increase in initial solute concentration in liquid decreases pore radius and times for bubble entrapment.

Opposite directions of solute transport across the cap submerged into a thick concentration boundary layer along the solidification

front, however, cannot result in bubble entrapment, because solute increases and decreases rapidly in late stage in Cases 2 and 3,

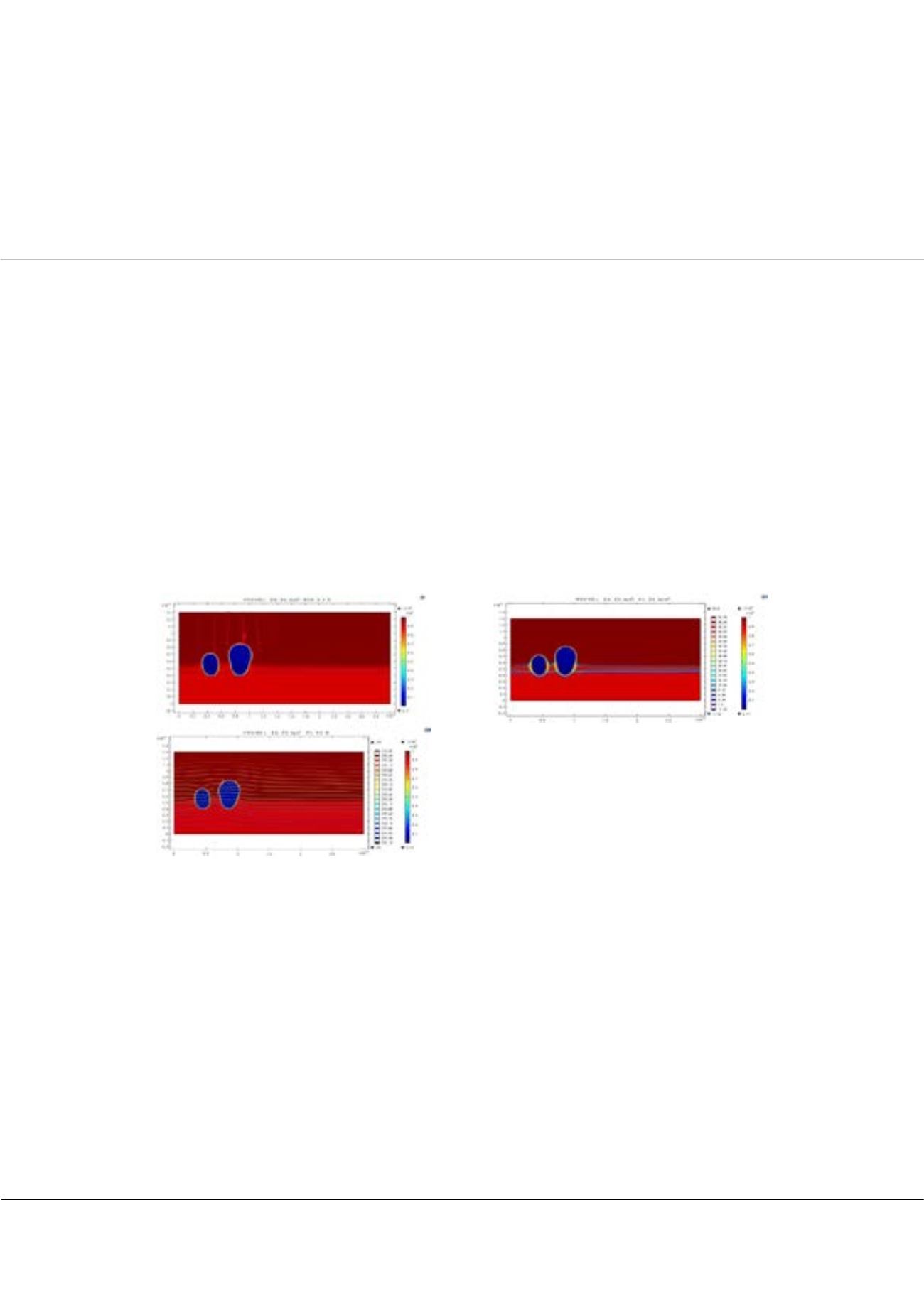

respectively. The predicted pore shape in solid agrees with experimental data. Numerical computations of development of the pore

shape associated with transport processes of fluid flow, temperature and concentration are also presented in Fig. 1.

Fig. 1 Predicted pore shape, and distributions of velocity, temperature and solute concentration fields of two pores at a time of 0.0102 s in Case 1.

Recent publications

1. Wei P S and Chao T C (2016) The effects of drilling parameters on pore size in keyhole mode welding. ASME Journal of

Manufacturing Science and Engineering 138:021008.

2. Wei P S and Chang C C (2016) Existence of universal phase diagrams for describing general pore shape resulting from

an entrapped bubble during solidification. ASME Journal of Heat Transfer 138:104503.

3. Wei P S and Hsiao S Y (2016) Effects of mass transfer coefficient on pore shape in solid. International Journal of Heat

and Mass Transfer 103: 931-939.

4. Wei P S and Hsiao S Y (2016) Effects of solute concentration in liquid on pore shape in solid. International Journal of

Heat and Mass Transfer 103: 920-930.

5. Hsiao S Y and Wei P S (2016) Case study of terrestrial or ambient pressure effects on pore shape in solid. AIAA Journal

of Thermophysics and Heat Transfer 31(4):796-804.

Peng-Sheng Wei, J Biotechnol Biomater 2018, Volume 8

DOI: 10.4172/2155-952X-C1-088