Page 48

conferenceseries

.com

Volume 9

Journal of Bioremediation & Biodegradation

ISSN: 2155-6199

Biofuel Congress 2018 &

Biomass 2018

September 04-06, 2018

JOINT EVENT

September 04-06, 2018 | Zurich, Switzerland

13

th

Global Summit and Expo on

Biomass and Bioenergy

&

12

th

World Congress on

Biofuels and Bioenergy

Bioethanol Production from Perennial Grasses

Satyawati Sharma

1

, Kalpana Arora

2

and

Garima Tiwari

1

1

Centre for Rural Development and Technology, IIT Delhi-New Delhi

I

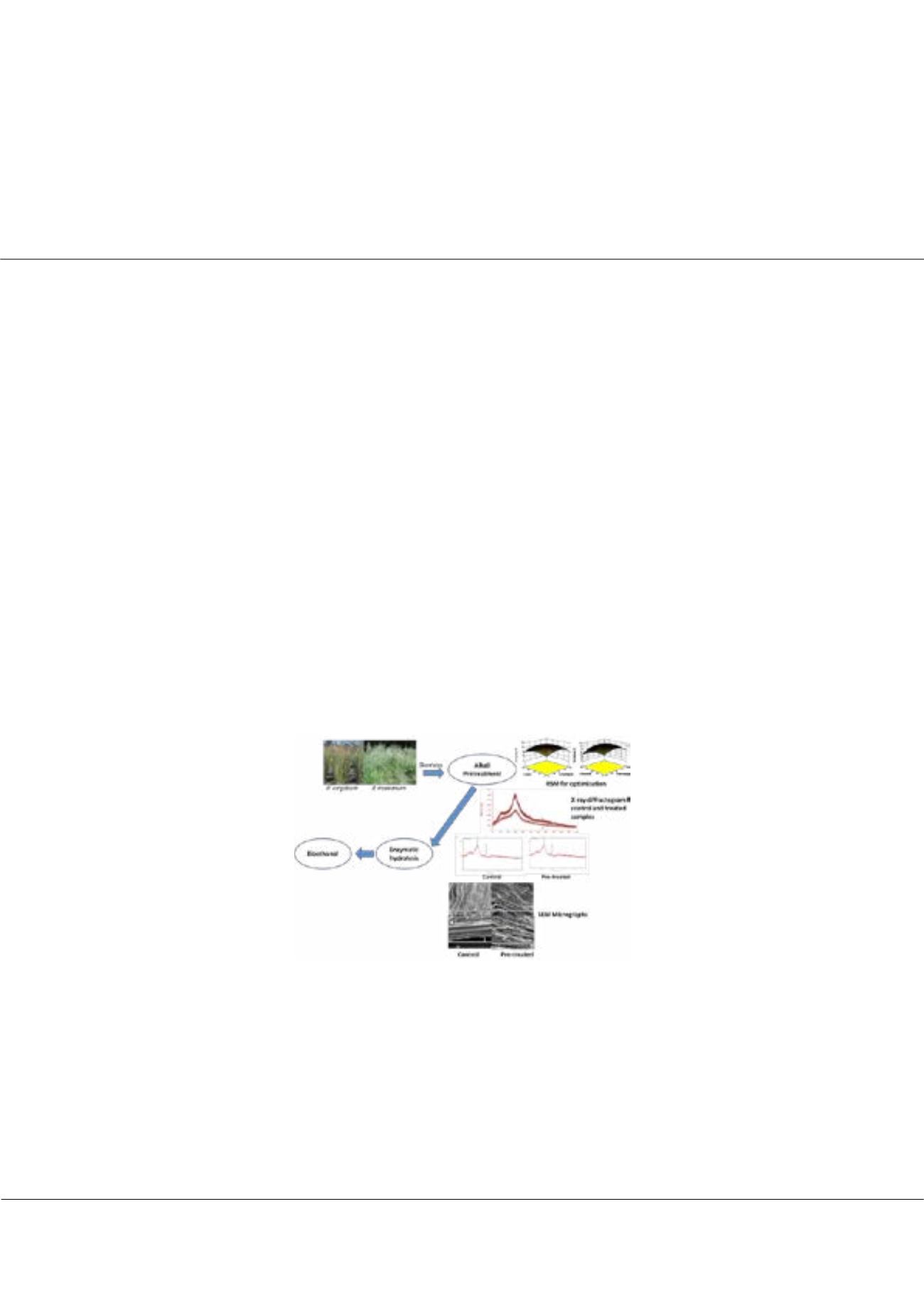

n the present demand for renewable and sustainable sources of energy to overcome the burden of world energy crisis, perrenial

grasses present exciting options.

Panicum virgatum

(Switchgrass) the ligno-cellulosic perennial grass, being considered as a

cheaper and efficient feedstock for bioethanol production in Europe and USA, could also be utilized in India for same purpose.

The present work focuses on cultivation of

P. virgatum

(very first time in India) and

P. maximum

, for bioethanol production. The

seeds of the Switch grass were obtained from Univ. of Bologna, Italy, while of guinea grass from IGFRI, Jhansi, UP, India. Both

the grasses were cultivated in Micromodel (an experimental field site), IIT Delhi. The harvested grass biomass was analyzed for

various parameters including reducing sugars for subsequent bioethanol production. Among different pretreatment methods

(Acid pretreatment, Alkali pretreatment and Microwave pretreatment) tested , alkali method showed maximum reducing

sugars (280 mg/g for

P. virgatum

and 262 mg/g for

P. maximum

) with 15 % reduction in crystallinity of cellulose in

P. virgatum

and 12% in

P. maximum

. It was further optimized with RSM and CCD was applied. Joint effects of four independent variables:

NaOH (1-5%), temp. (60-100 ºC), substrate loading (1-3%), and reaction time (30-150 min), were investigated to increase in

reducing sugar content. The combined optimum conditions for maximum reducing sugar (68.3% ) were: 2.5% substrate, 5%

NaOH, a reaction time 120 min at 100 ºC. The result analyzed (ANOVA) with a second order polynomial equation. showed

62 - 68 % significant increase in reducing sugars. The calculated theoretical ethanol production from switch grass was found

to be 26.72%, while for

P. maximum

it was 25.24%. This study reveals that under optimized pretreatment conditions, sugar

yield is significantly increased and promises the use of both

P. virgatum

and

P. maximum

grasses as feedstock for bioethanol

production in India also. All the findings pertaining to all steps in cultivation, characterization, pretreatment and hydrolysis

methods and bioethanol from these grasses will be presented at conference.

Recent Publications

1. Adak, A., Tiwari, R., Singh, S., Sharma, S., & Nain, L. (2016) Laccase Production by a Novel White-Rot Fungus,

Pseudolagarobasidium acaciicola LA 1 Through Solid-State Fermentation of Parthenium Biomass and Its Application in

Dyes Decolorization.

Waste and Biomass Valorization,

7, 1427-1435.

2. Arora, K., Sharma, S., &Monti, A. (2016) Bio- remediation of Pb and Cd polluted soils by switchgrass: A case study in India.

International Journal of Phytoremediation,

7(18), 704-709.

3. Arora, K.; Kumar, A., & Sharma, S. (2012) Energy fromWaste: Present Scenario, Challenges and Future Prospects towards

Sustainable Development. IGI Global, 271-296.

Satyawati Sharma et al., J Bioremediat Biodegrad 2018, Volume 9

DOI: 10.4172/2155-6199-C1-014