Page 57

conferenceseries

.com

Volume 9

Journal of Bioremediation & Biodegradation

ISSN: 2155-6199

Biofuel Congress 2018 &

Biomass 2018

September 04-06, 2018

JOINT EVENT

September 04-06, 2018 | Zurich, Switzerland

13

th

Global Summit and Expo on

Biomass and Bioenergy

&

12

th

World Congress on

Biofuels and Bioenergy

Microalgae cultivation in continuous reactor using mixotrophic anaerobic effluent: effect of dilution

rate on biomass productivity and tertiary treatment

Servio Tulio Cassini, Marcos V N L Pereira, Aline Dassoler

and

Ricardo F Goncalves

UFES, Brazil

M

icroalgae are continuously attracting main attention from biomass researchers, especially due to their capacity of

fast growth, CO

2

abatement and land-free cultivation as compared with conventional crops. Additionally, municipal

wastewater has been long recognized as a suitable media for the cultivation of microalgae biomass. Culturing microalgae

with wastewater effluents also promotes a process of tertiary treatment, characterized by removal of main nutrients (N, P)

from wastewater and simultaneously achieving high biomass productivities. However, few studies report data concerning

biomass productivity in continuous mode using unsterilized mixotrophic wastewater effluent and we found no reports of E.

coli population decay rates in these continuous reactors. This study focuses on the selection of native microalgae strains that

are applicable for biomass production and tertiary wastewater treatment in continuous mode. Five strains were isolated and

cultivated in unsterilized anaerobic effluent in batch growth mode, to identify the efficient microalgae isolates for biomass

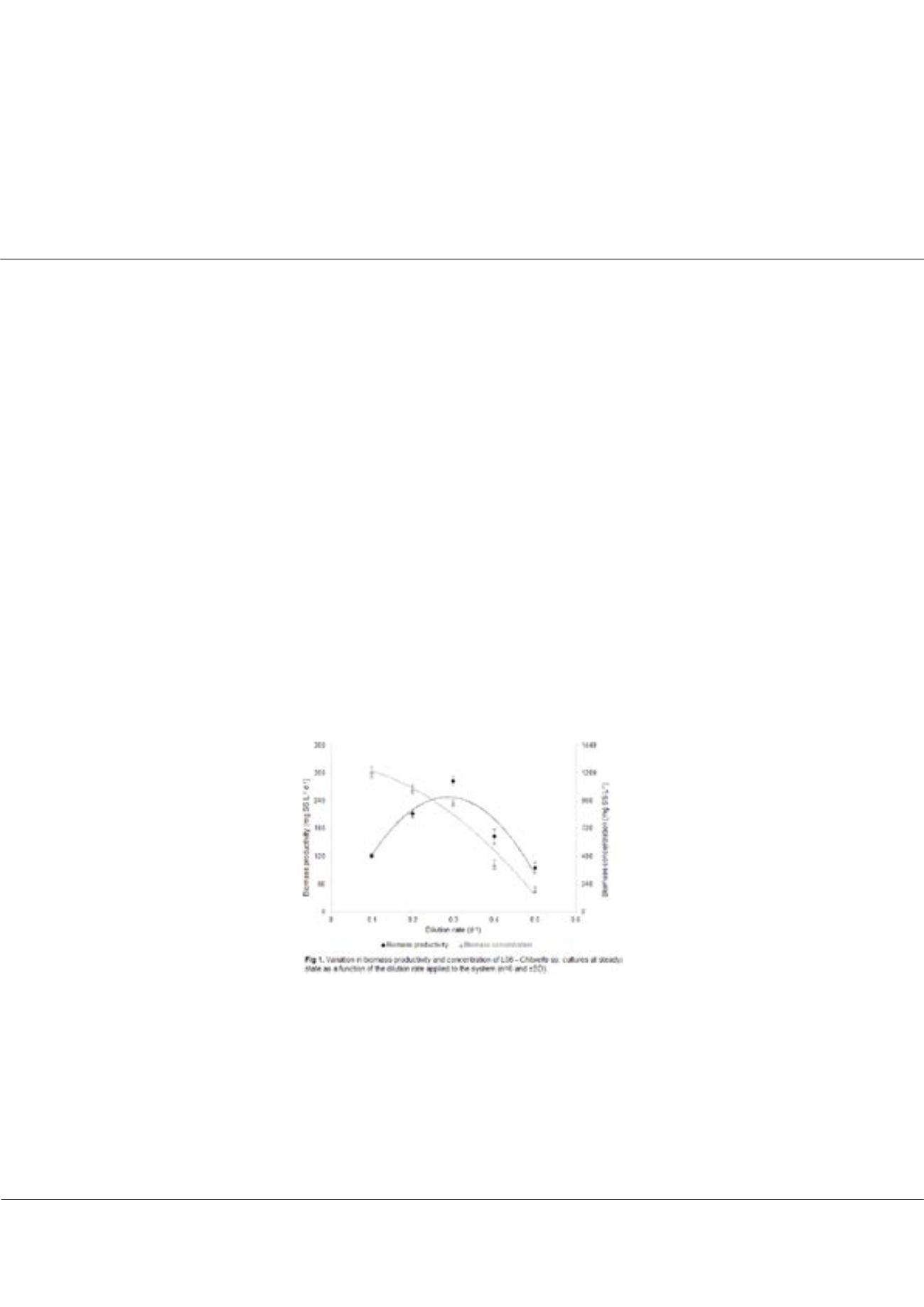

conversion. The isolate L06 (Chlorella sp.) was selected and evaluated based on five dilution rates from 0.1 to 0.5 1/day on

continuous growth reactor, resulting in five steady state conditions. Maximal volumetric biomass productivity of 294 mg/L day

was obtained at 0.3 1/day without CO

2

addition or air bubbling. Carbohydrates were the major fraction of the dried biomass,

followed by proteins and then lipids. The highest removal rates of total nitrogen and phosphorus from the liquid phase were

13.0 and 1.4 mg/L day, respectively, and were achieved at 0.4 1/day. The maximal decay rate for E. coli (3.7 1/day) was also

achieved at this dilution rate, representing approximately a 99.9% population reduction of this bioindicator over a period of 2.5

days. Therefore, L06 – Chlorella sp. continuous cultivation using secondary-treated wastewater can be adjusted depending on

its objective: for biomass production, a dilution rate of approximately 0.3 1/day is recommended; and for tertiary treatment a

rate of 0.4 l/day is suggested.

Recent Publications

1. Caporgno et al. (2015) Microalgae cultivation in urban wastewater: Nutrient removal and biomass production for biodiesel

and methane. Algal Research 10:232-239

2. Gonçalves A L, Pires J C M and Simões M (2016) Biotechnological potential of Synechocystis salina co-cultures with

selected microalgae and cyanobacteria: Nutrients removal, biomass and lipid production. Bioresource Technology 200:279-

286.

Servio Tulio Cassini et al., J Bioremediat Biodegrad 2018, Volume 9

DOI: 10.4172/2155-6199-C1-014