Page 81

conferenceseries

.com

Volume 7

Innovative Energy & Research

ISSN: 2576-1463

Advanced Energy Materials 2018

August 13-14, 2018

August 13-14, 2018 | Dublin, Ireland

20

th

International Conference on

Advanced Energy Materials and Research

Superior hydrogenation/dehydrogenation kinetics of MgH

2

nanopowders upon mechanical doping

with amorphous Zr

2

Ni

Fahad Al-Ajmi

Kuwait Institute for Scientific Research, Kuwait

H

ydrogen is an energy carrier, which holds tremendous promise as a new clean energy option. Hydrogen storage, which

is considered to be the most important factor cutting across both hydrogen production and hydrogen transportations,

has been the subject of intensive research for many years. Mg and Mg-based materials have opened promising concept for

storing hydrogen in a solid-state matter. The natural abundance, cheap price, operational cost effectiveness, light weight, and

high hydrogen storage capacity (7.60 wt.%, 0.11 kg H

2

L

−1

) are some advantages of Mg and Mg-based alloys making them

desirable storage materials for research and development. Whereas all catalytic materials used to improve the behaviors of

hydrogenation/dehydrogenation kinetics for MgH

2

have long-range order structure, the present work proposes two different

types of structure; i.e. short range- and medium range- order. For the purpose of the present study, MgH

2

powders were

prepared by reactive ball milling of Mg powders under 50 bar of H

2

, using room-temperature high-energy ball mill [5]. Ultrafine

powders of amorphous- and big cube-Zr

2

Ni phases were prepared by ball milling small bulk pieces of tetragonal-Zr

2

Ni alloy

prepared by arc melting technique. Small volume fraction (10 wt. %) of amorphous and big- cube powders obtained after ball

milling for 100 and 150 h, respectively were individually mixed with as-synthesized MgH

2

powders and then ball milled for 50

h. The results have shown that nanocomposite MgH

2

/10 wt.% metallic glassy Zr

2

Ni powders had high density of hydrogen (~6

wt.%) and possessed fast kinetics of hydrogen uptake/release at 250°C within 1.15 and 2.5 min, respectively. Whereas, MgH

2

/10

wt.% of big cube Zr

2

Ni nanocomposite showed moderate improvement on hydrogenation (1.8 min)/dehydrogenation (7 min)

kinetics due to the heterogeneous distribution of their particles onto the MgH

2

powders.

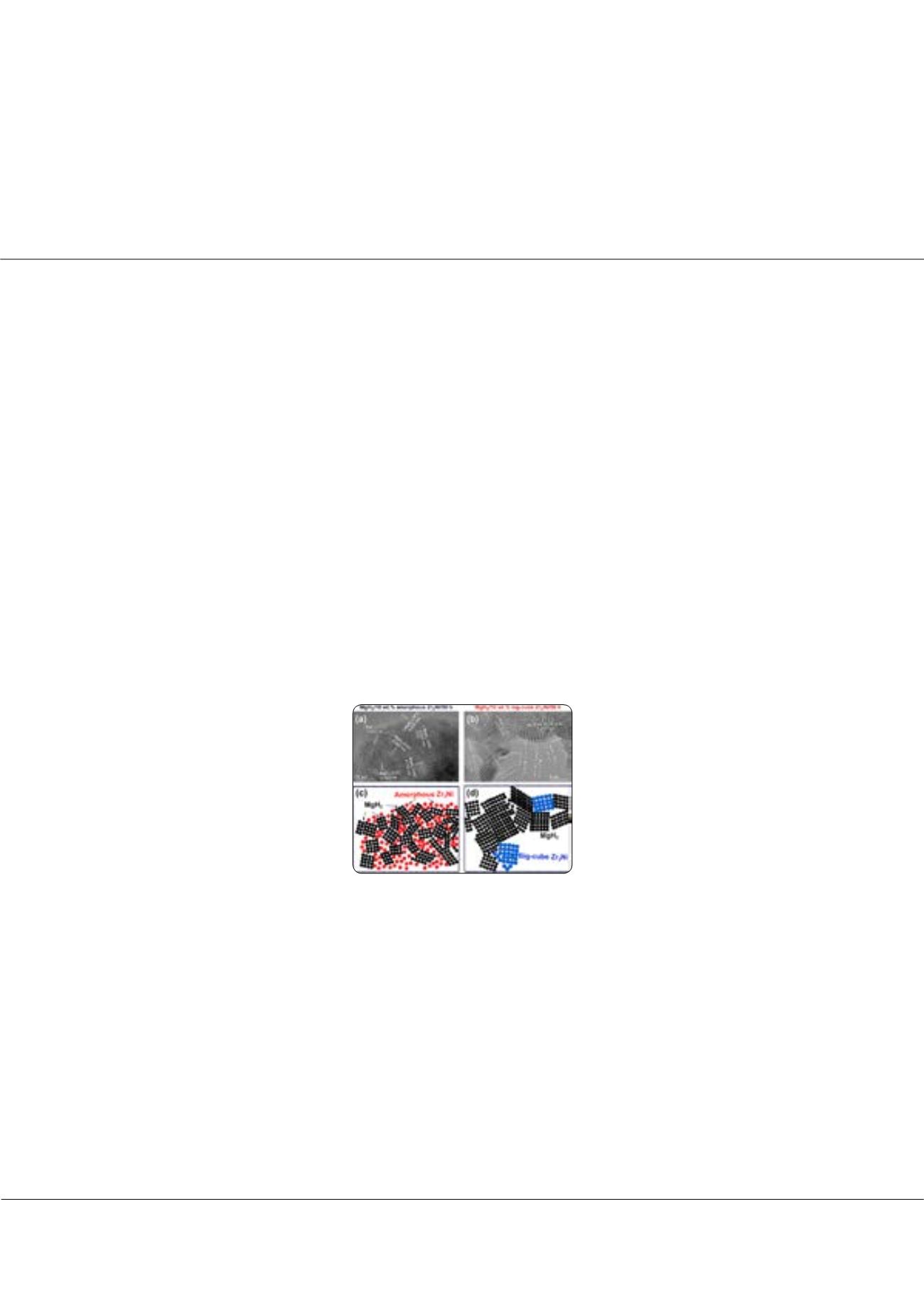

Fig.

HRTEM images of nanocrystalline MgH

2

powders doped with 10 wt.% of (a) amorphous Zr

2

Ni, and (b) big-cube Zr

2

Ni nanopowders. The corresponding

illustration sketches for the HRTEM images shown in (a) and (b) are displayed in (c) and (d), respectively.

Recent Publications:

1. El-Eskandarany, M. Sherif (2017) Synthetic nanocomposite MgH

2

/5 wt. % TiMn

2

powders for solid hydrogen storage

tank integrated with PEM fuel cell Nature, Sci. Rep. 7: 13296; doi: 10.1038

/s41598-017-13483-0.www.nature.com/scientificreports.

2. El-Eskandarany, M. Sherif et al. (2017) Structure, morphology and hydrogen storage kinetics of nanocomposite

MgH

2

/10 wt% ZrNi

5

powders, Materials Today Energy, 3: 60-71.

3. El-Eskandarany, M. Sherif et al. (2016) In-situ catalyzation approach for enhancing the hydrogenation /

dehydrogenation kinetics of MgH

2

powders with Ni particles. Sci. Rep. 6, 37335; DOI: 10.1038/srep37335 www.

nature.com/scientificreports.4. El-Eskandarany, M. Sherif (2016) Metallic glassy Zr

70

Ni

20

Pd

10

powders for improving the hydrogenation/

dehydrogenation behavior of MgH

2

. Nature, Sci. Rep. 6, 26936; doi: 10.1038/srep26936.

www.nature.com/scientificreports.

Fahad Al-Ajmi, Innov Ener Res 2018, Volume 7

DOI: 10.4172/2576-1463-C1-002