Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

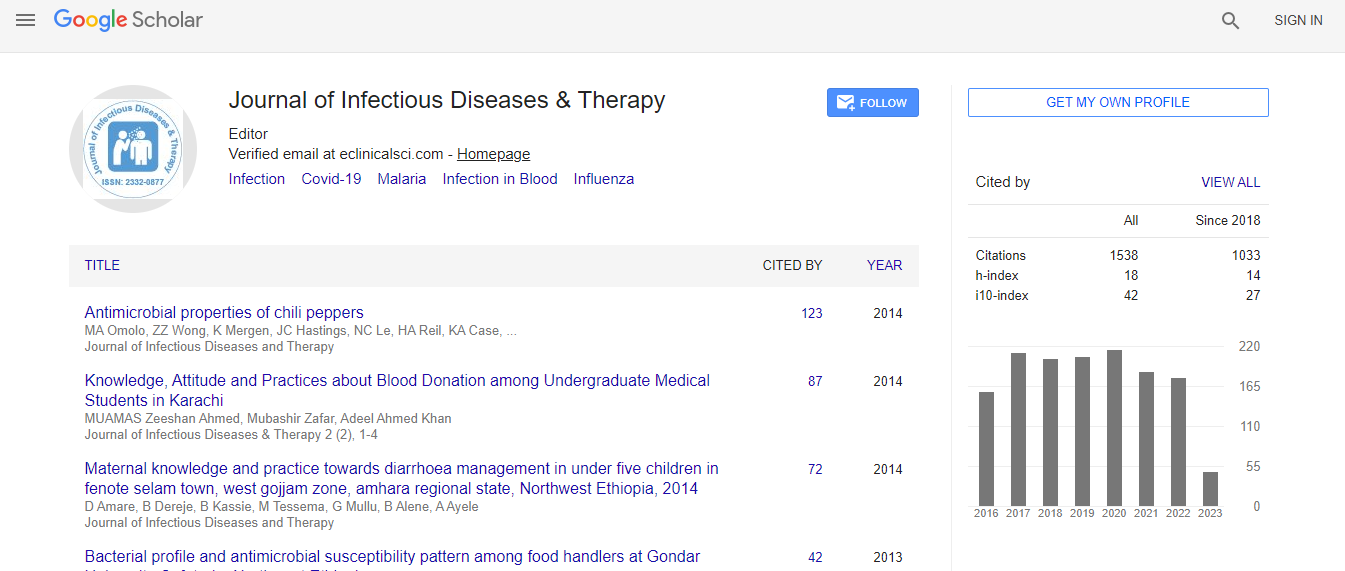

Google Scholar citation report

Citations : 1529

Journal of Infectious Diseases & Therapy received 1529 citations as per Google Scholar report

Indexed In

- Index Copernicus

- Google Scholar

- Open J Gate

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Uniform films on 2D/3D surfaces/gadgets leading to quasi-instantaneous bacterial inactivation: A new route to reduce healthcare acquired infections

Joint Event on 2nd International Congress on Nosocomial and Healthcare Associated Infections & International Conference on Decontamination, Sterilization and Infection Control

Sami Rtimi

Swiss Federal Institute of Technology, Switzerland

Keynote: J Infect Dis Ther

Abstract

During the last few decades, the increase of infections by toxic pathogens/biofilms leading to hospital-acquired infections (HAI) has motivated work in the area [1-2]. More advanced antibacterial films presenting uniform distribution, high adhesion to flexible non-thermal resistant substrates, mechanical resistance and faster bacterial/biofilm inactivation under light or in the dark are needed due to health concerns [1]. TiO2 films have been used under light>387 nm generating highly oxidative radicals as bactericide films for many years [2]. However, its restricted absorption of solar/visible light and slow bacterial inactivation kinetics has motivated workers to dope TiO2 with Cu or Ag to shift the absorption of the films to the visible region. This doping also precludes recombination of the photo-generated charges. Stable, adhesive uniform films of TiO2 inactivated bacteria within 40 min [2]. But TiO2/Cu (Cu≥ 0.1%) films led to bacterial inactivation < 10 min under actinic light (4mW/cm2) [3-4]. Next, the sputtered Cu for 5-10s (0.01% by weight/ppb levels) on TiO2-ZrO2 layers on polyester [5] accelerated the kinetics by a factor of 3 with respect to films where the Cu was absent. The Cu intra-gap states seem to: a) accelerate the indirect transitions in the TiO2/ZrO2 during the interfacial charge transfer (IFCT), b) preclude recombination of the photo-generated charges, and c) induce Cu-redox reactions during the inactivation time. Since today’s focus of interest is to increase the visible absorption of antibacterial surfaces, further work addressed the preparation of FeOx-TiO2 on polyethylene (PE) flexible films. The FeOx-TiO2 hetero-junctions obtained presented random distribution for both oxides and led to electron injection from the FeOx under visible light to TiO2 lower lying trapping states inactivating bacteria within 60 min compared to 210 min for TiO2 films by themselves [6]. The most recent work in this area focuses on metal/bimetal films driving bacterial inactivation. Hybrid Cu-Ag (50%/50%) nanoparticle metal-oxide amalgamated films able to generate highly oxidative radicals have been investigated leading to a quasi-instantaneous bacterial inactivation under low-intensity actinic light and in the dark [7]. The release of Cu/Ag-ions during bacterial inactivation was below the cytotoxicity levels permitted by the sanitary regulations. Cu and Ag are partially covered with their oxides when exposed to air and the composite Cu-Ag-polyurethane (PU) therefore contains amalgamated CuO-Ag2O. The future development of 2D-films/3D-gadgets needs to consider their biocompatibility. In addition to the application of the metal/oxide for surgical/cutting tools, some industries recently started technologies to develop tools in the dental surgery and in spine/orthopedic implants. The substrates used are in the majority heat-resistant. In this case, the novel 2D or 3D antibacterial films shown herein can be used without further heating, which enables their use for non-heat resistant substrates.Biography

Sami Rtimi is a Biologist with a strong background in material’s chemistry and catalysis. He was awarded a Ph.D. in Chemistry and Chemical Engineering from Swiss Federal Institute of Technology-EPFL (Thin films for healthcare acquired infections (HCAIs) prevention: materials preparation, testing and characterization, EPFL, Switzerland) and a Doctorate in Biological Sciences from the University of Carthage. He is investigating smart materials for nosocomial infections reduction and biomedical applications. He is an expert in coupling nanostructured materials for targeted bio-response at the solid-air and the solid-liquid-interfaces.

E-mail: sami.rtimi@epfl.ch

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi