Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

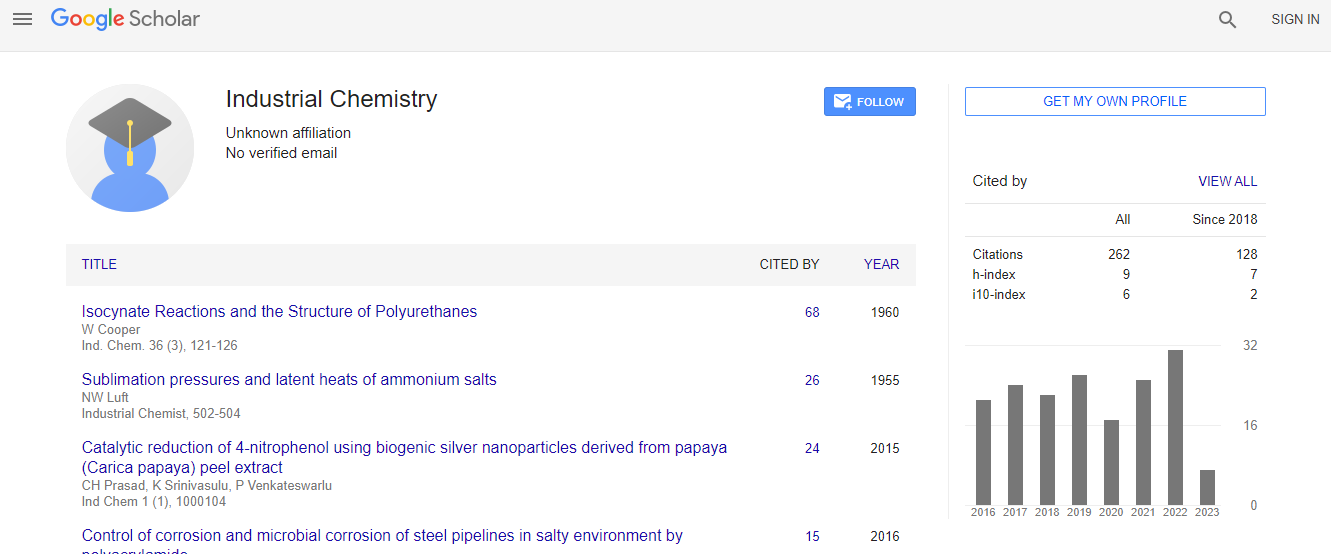

Google Scholar citation report

Citations : 262

Industrial Chemistry received 262 citations as per Google Scholar report

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Thermal sterilization of microorganisms

International Conference on Industrial Chemistry

Muhammad Shahid

University of New South Wales, Australia

ScientificTracks Abstracts: Ind Chem

Abstract

Clean and safe drinking water is a limited natural resource and a public good fundamental to life and health. The human right to water is indispensable for leading a healthy life in human dignity, but unfortunately these water assets are being depleted immensely all over the world. The aim of the bubble column evaporator (BCE) theme is to develop new concepts, and to improve existing purification technologies in terms of energy and cost effectiveness, which can guarantee highquality water in the future. The simple bubble column evaporator presents an interesting challenge to our understanding of the detailed processes involved in bubble rise rate, water vapour evaporation and the variable effects of different solutes on bubble coalescence inhibition. Fortunately, the most important and common salt, sodium chloride, acts in solution to inhibit bubble coalescence and that behaviour has been applied to the development of a wide range of useful techniques based on the bubble column evaporator. This complex system has recently been used to develop a novel method for sub-boiling, thermal sterilization, a thermal desalination and its improvement and a new method for the precise determination of enthalpies of vaporization of concentrated salt solutions. A bubble column was used to study sterilization using bubbles of different sizes (mm to cm) produced via bubble coalescence or by inhibiting coalescence through the addition of NaCl. The rapid transfer of heat from small, hot (dry) gas bubbles to the surrounding water was used as an effective and energy efficient method of sterilizing contaminated water. It is shown that the continuous flow of (dry) hot gases, even at 250�°C, only heat the aqueous solution in the bubble column to well below sub-boiling temperature and it was also established that coliforms are not significantly affected by even long term exposure to this solution temperature. Hence, the effects observed appeared to be caused entirely by collisions between the hot gas bubbles and the coliform particles close to the sinter, where the gas bubbles were still hot enough (i.e., within 5-10 cm of the sinter surface). It was also established that the use of high air inlet temperatures can reduce the thermal energy requirement to only about 14 % (about 64 kJ/L) of that required for boiling (about 450 kJ/L).Biography

Muhammad Shahid is currently a PhD candidate in UNSW Canberra and conducting research in desalination and water treatment technology. Also, he has obtained a Bachelor’s degree in Chemical Engineering and a Master’s degree in Environmental Engineering from N.E.D University of Engineering and Technology, Karachi, Pakistan in 2002 and 2010 respectively. Moreover, he has got seven years professional experience as a chemical engineer.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi