Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

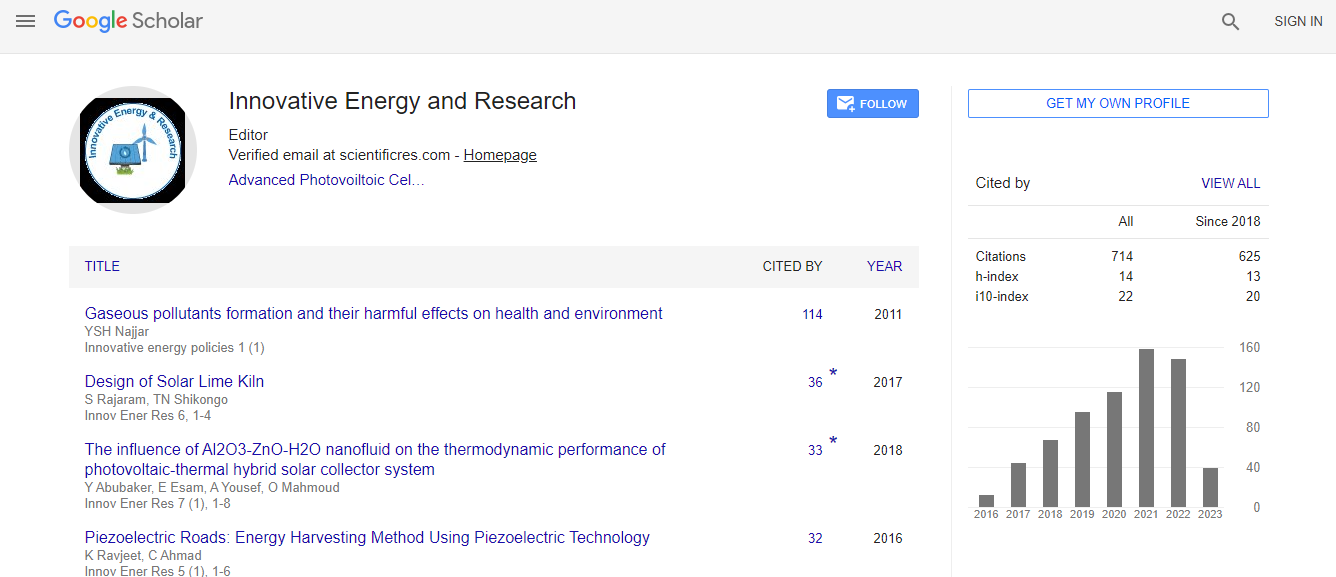

Google Scholar citation report

Citations : 712

Innovative Energy & Research received 712 citations as per Google Scholar report

Innovative Energy & Research peer review process verified at publons

Indexed In

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Thermal performance of the latent heat storage units with aluminium porous structures

Joint Event on 2nd International Conference on Renewable Energy and Resources & Energy Materials and Fuel Cell Research

Krzysztof Naplocha, Anna Dmitruk and Jacek Kaczmar

Wroclaw University of Science and Technology, Poland

ScientificTracks Abstracts: Innov Ener Res

Abstract

The heat accumulators based on phase change materials (PCM) operate in charging/discharging cycles. Their effectiveness depends on the heat transfer rate and value of the latent heat of melted and solidified materials. Usually, they characterized by low thermal conductivity what increases thermal gradient inside the chamber and prolongs charging time. In order to enhance heat transfer from energy source various metal shapes like fins, pipes or foams can be embedded in PCM. Investment casting method offers manufacturing highly porous structures with developed surface and appropriate stiffness. In this work examination of heat transfer of composite PCM included paraffin and aluminium alloy spatial casting are shown. Thermal performance of laboratory accumulator with pure paraffin was tested and compared with results determined when metal foam or honeycomb structures were introduced into paraffin. Metal inserts accelerating heat transfer melted or cooled paraffin faster and thus charging/discharging time is reduced. Performed multiple charging cycles revealed some issues with fatigue damage of metal foam. In comparison to pure paraffin metal structures reduced temperature gradient within the chamber accumulator ca. 2-3 times. Convection of liquid paraffin can be slightly restricted therefore arrangement of honeycomb channels was examined and favorable position determined.Biography

Krzysztof Naplocha has completed his PhD at the age of 33 years from Wrocclaw University o Science and Technology. He has been involved in various science project covering metal matrix composite materials reinforced with ceramic fibers or intermetallic skeletons. Currently, he is developing high porous metal structures produced by metal casting. Much of his work has been on improving heat transfer in energy storage systems. He has published more than 120 papers in reputed journals and is the co-author of Intermetallic matrix composites: properties and applications (Woodhead Publishing, 2018) and Advances in materials science research (NY: Nova Science Publishers, 2012).

E-mail: krzysztof.naplocha@pwr.edu.pl

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi