Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

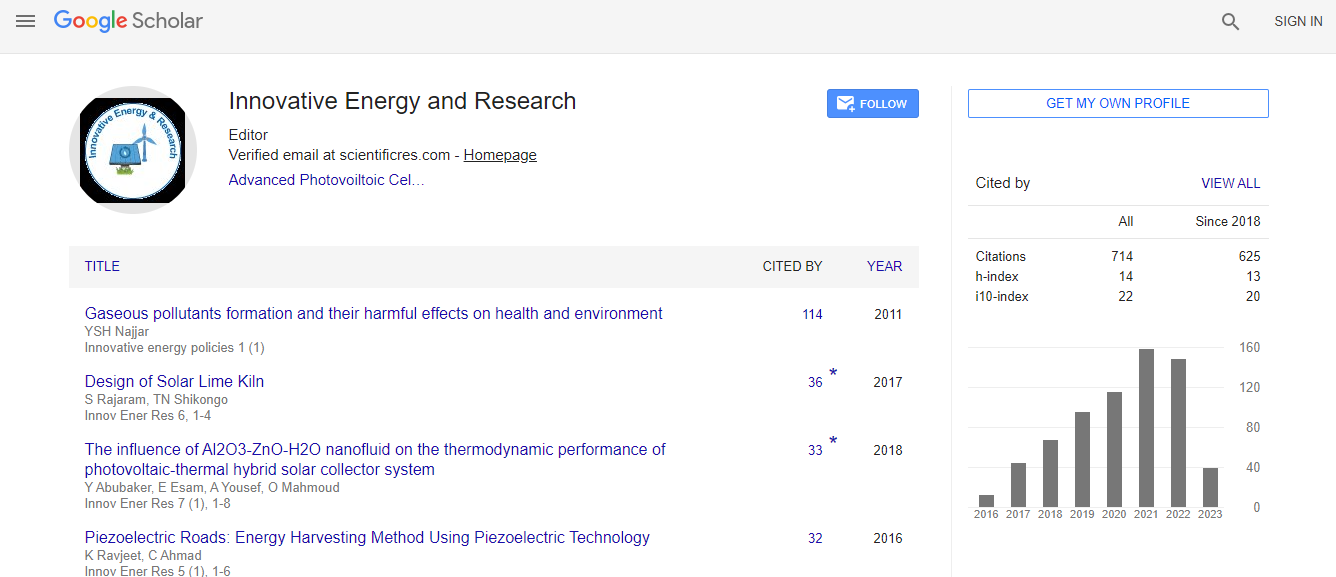

Google Scholar citation report

Citations : 712

Innovative Energy & Research received 712 citations as per Google Scholar report

Innovative Energy & Research peer review process verified at publons

Indexed In

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Research and development results on advanced materials for light water reactors and future works

20th International Conference on Advanced Energy Materials and Research

Toshio Yonezawa

Tohoku University, Japan

Posters & Accepted Abstracts: Innov Ener Res

Abstract

In the nuclear power industrial field, all materials for nuclear power plants must be materials that have sufficient experience in other industrial fields, or those that have been sufficient comprehensive test data accumulated. Author has been studying on the many kinds of advanced materials for many components of the light water reactors, during more than 47years. For example, Thermally Treated Alloy 690 which is applying to steam generator tubes, control rod drive mechanism tubes, etc., for pressurized water reactors (PWRs) in a world, irradiation assisted stress corrosion cracking (IASCC) resistant modified 316 stainless steel which is applying to baffle former bolts and barrel volts of core internals for Japanese PWRs, Iron base wear resistant alloy which is applying to valve sheets for Japanese PWRs, etc. And also, author has developed on new conceptual stress corrosion cracking (SCC) resistant austenitic stainless steel. The SCCs were detected in non-sensitized but heavily cold worked austenitic stainless steels for some components of boiling water reactors (BWRs). So, author idealized that the SCC should be caused by low stacking fault energy of that stainless steel, and developed the highly SCC resistant austenitic stainless steel which has high stacking fault energy, based upon the comprehensive basic study, as shown in Figure 1. Author has studied on the comprehensive long-term corrosion tests and SCC tests, mechanical tests, weldability tests, inspectability tests, etc., for these advanced materials, to apply to the components of commercial PWRs or BWRs. Even after these advanced materials have been applied practically, author has been continuing the studies on the long-term corrosion, SCC test, etc., as pro-active research up to the end of plant life for light water reactors. That is a feature of the field of nuclear industry, and the material used for nuclear power plants must never be disposable on the spot.Biography

E-mail: t-yonezawa@fri.niche.tohoku.ac.jp

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi