Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

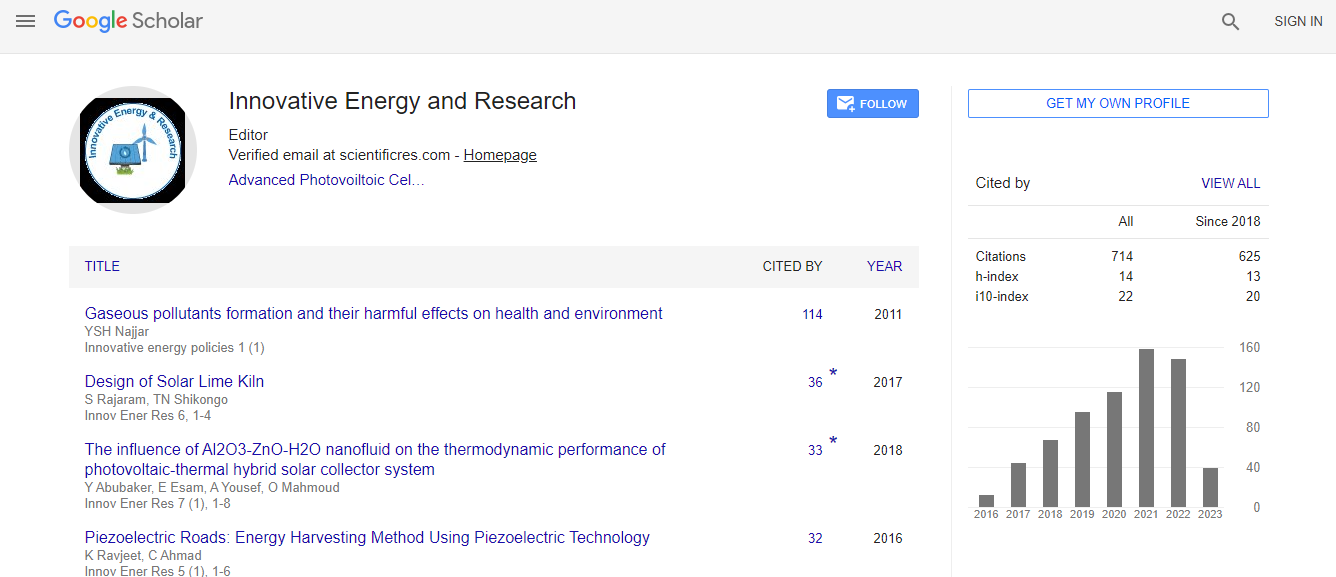

Google Scholar citation report

Citations : 712

Innovative Energy & Research received 712 citations as per Google Scholar report

Innovative Energy & Research peer review process verified at publons

Indexed In

- Google Scholar

- Open J Gate

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Progress into energy storage technology: About the carborundum foam ceramic structure and the fuel cells capacity

21st International Conference on Advanced Energy Materials and Research

Karim Ragui

USTHB University of Sciences & Technology, Algeria

Posters & Accepted Abstracts: Innov Ener Res

Abstract

The present research is about carborundum foam ceramic (SiC) and its huge energy storage capacity in industrial approaches. Initially observed in 1824 by Jöns J Berzelius in a synthetic diamond experience by a parasite reaction between carbon and silica, this porous material is found much utilized since the industry of 1890, raison to its precious properties, such as its powerful resistivity to thermal shocks and chemical oxidation to name but a few. SiC could be produced at various specific surfaces, as between 10 and 20 m2/g. Similarly, the granulometric composition of the used mixture powder could control its porosity. For industrial applications (as catalysts), the porosity is ranged between 37% and 45%. Regarding the permeability the key factor for most industrial applications, a large range of the latter could be denoted. Complement to these properties and following the fuel cells development in the recent years, such a material could be adopted against the storage instability problem. As observed with various fluid natures, it was established that the energy storage at low double-diffusive buoyancies consists, usually of a steady state ratio, easily controlled at pilot processes (and promotive for modest applications). By searching for a better capacity ratio, following the increase in the buoyancy impact, the fuel cell structure could become unstable, leading to a huge loss in both the process energy cost and the used materials. Facing to such a big challenge, our alternative will be themo-mechanical. By taking the annulus shapes as an example, the generation of a high diffusive gradient between the annulus limits could increase the buoyancy efficiency and the energy ratio consequently. Of course critical situations will be reached, as the inner sub-flow regimes over the energy storage process. Against such a part, the full cell shape could light-up the perfect solution. In view of the fact that the nature of industrial processes is often non-linear, extremely complex and not sufficiently recognized, the development of primary conditions for energy storage optimization is of practical significance. As such, our presentation at Advanced Energy Materials Conference, at Zurich, Switzerland, will be undertaken to extend the optimum carborundum foam structure & buoyancy range to make accurate information about full cells stability and the evolution of the energy storage ratio during the operation time.Biography

E-mail: ragui-karim@live.fr

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi