Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

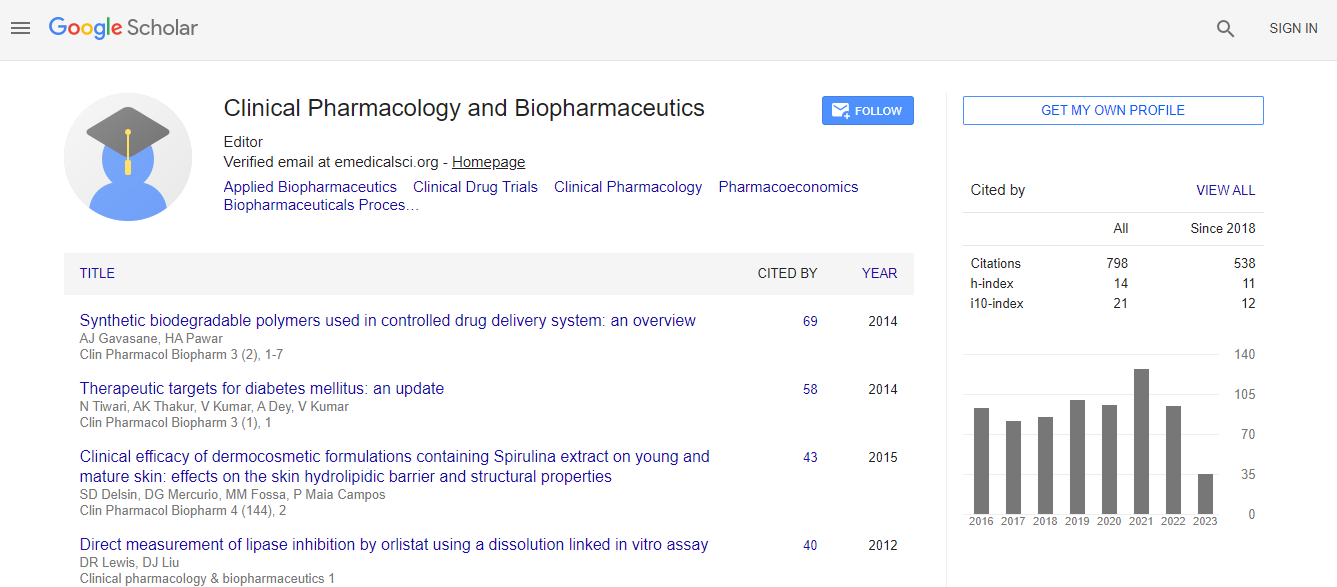

Google Scholar citation report

Citations : 1089

Clinical Pharmacology & Biopharmaceutics received 1089 citations as per Google Scholar report

Clinical Pharmacology & Biopharmaceutics peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Optimizing the timing and number of batches for compounded sterile products in an in-hospital pharmacy

3rd International Conference on Clinical Pharmacy

Vera Tilson and Greg Dobson

University of Rochester, USA

Posters-Accepted Abstracts: Clin Pharmacol Biopharm

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi