Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

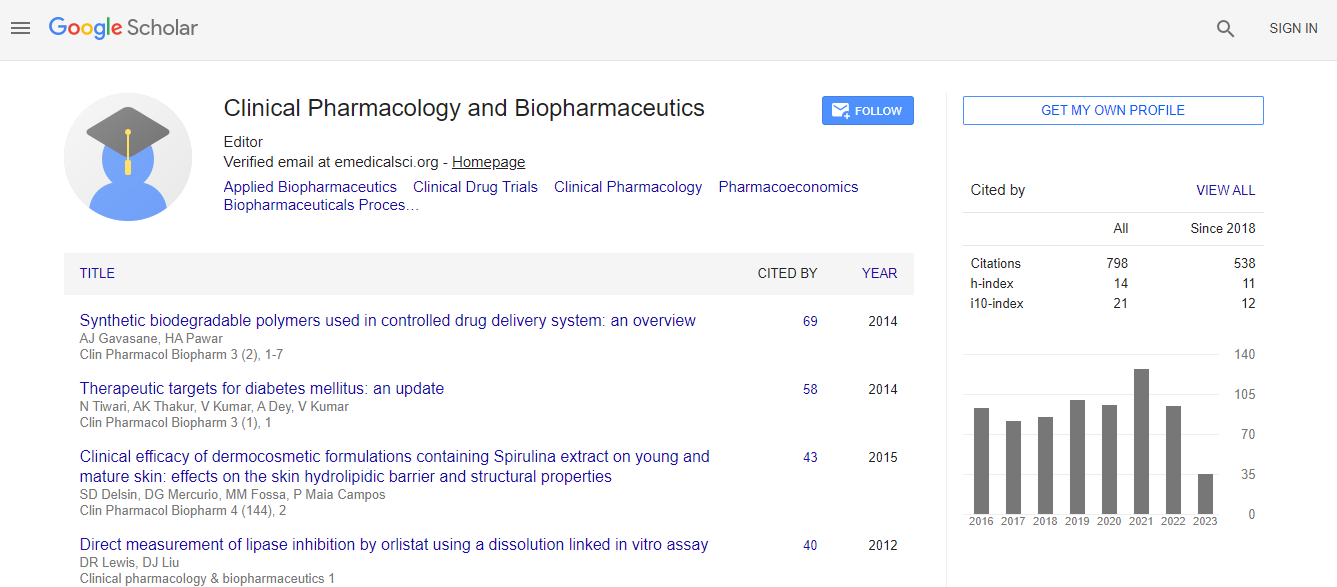

Google Scholar citation report

Citations : 1089

Clinical Pharmacology & Biopharmaceutics received 1089 citations as per Google Scholar report

Clinical Pharmacology & Biopharmaceutics peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Novel biodegradable polymeric nanoparticle development using quality by design

International Conference and Expo on Biopharmaceutics

Emmanuel O Akala

Howard University, USA

Posters-Accepted Abstracts: Clin Pharmacol Biopharm

Abstract

The relatively new concept of quality by design (QbD) in pharmaceutical dosage form design and development, already incorporated into automakersâ�?�? production principles, involves designing and developing drug formulations and manufacturing processes which ensure predefined drug product specifications. An important part of QbD is to understand how process and formulation variables affect product characteristics and subsequent optimization of these variables vis-�? -vis the final specifications. Statistical design of experiments (DoE) is a well-established method for identifying important parameters in a pharmaceutical dosage form design and optimizing the parameters with respect to certain specifications; DoE is a valuable tool to establish in mathematical form the relationships between critical process parameters (CPPs) together with the critical material attributes (CMAs) and critical quality attributes (CQAs). Further, DoE can help identify optimal conditionsquickly as well as facilitate robustness testing. Approaches to DoE (to examine all the variables simultaneously) are factorial and mixture experimental designs. When the responses or nanoparticle properties are known to depend on the proportions of the ingredients, DoE involving mixture methodologyis preferred. When a formulation is a mixture of various components (proportion of the constituents: macomonomer, crosslinker, stabilizer and initiator system) as studied in this work and the levels of the components are constrained, D-optimal mixture design is more useful than a factorial design because it accounts for the dependence of response on proportionality of constituents. Our data on two nanoparticle systems (fabricated by surfactant-free dispersion polymerization) will be presented: stealth biodegradable palctaxelloaded polylactide nanoparticles and stealth biodegradable docetaxel-loaded poly-�?µ-caprolactone nanoparticles.Biography

Email: eakala@Howard.edu

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi