Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

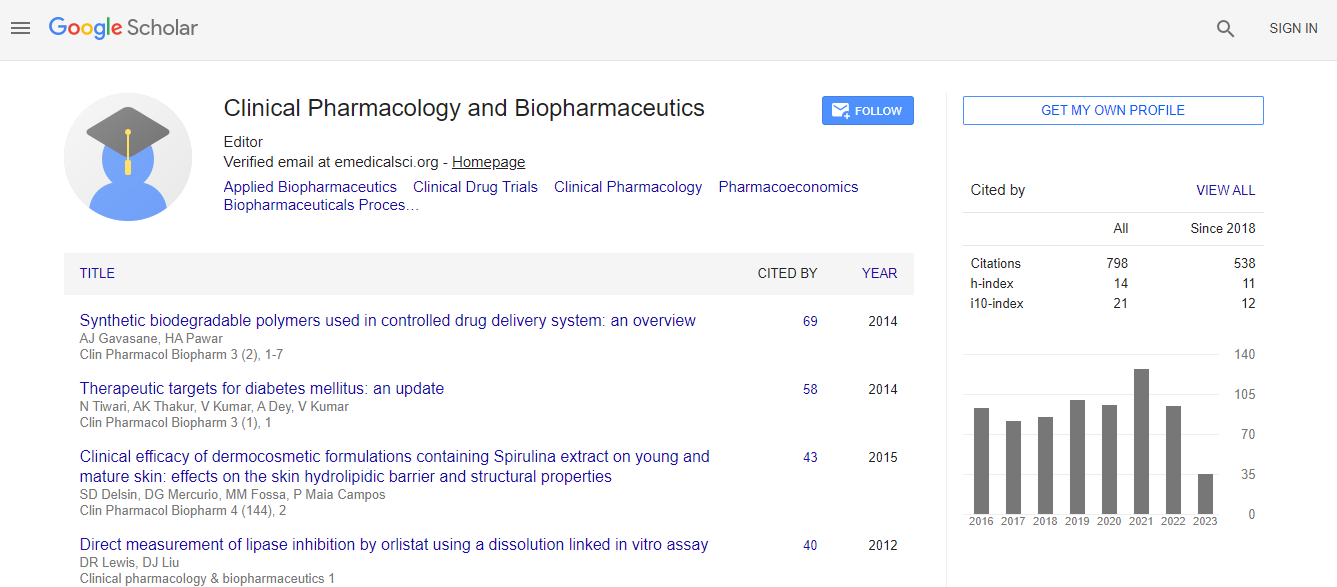

Google Scholar citation report

Citations : 1089

Clinical Pharmacology & Biopharmaceutics received 1089 citations as per Google Scholar report

Clinical Pharmacology & Biopharmaceutics peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Novel approach for the formulation of excipient-less fixed dose combination (FDC) tablets by Hot Melt Extrusion (HME) technology using quality by design approach

4th International Pharma & Clinical Pharmacy Congress

Kailas Kalicharan Moravkar

Institute of Chemical Technology, India

Posters & Accepted Abstracts: Clin Pharmacol Biopharm

Abstract

The objectives of the present study were to investigate the properties of HME based tablets containing plain ibuprofenparacetamol FDC, without a single excipient and to compare it with marketed formulation by applying QbD approach. Paracetamol and ibuprofen were taken at drug/drug mass ratios (5:2). The prepared physical mixtures were extruded using a corotating twin-screw hot melt extrusion. Among the three tested independent variables in DOE, temperature and feeding rate most significantly affected the tensile strength and drug release from the tablet. The melt extruded granules were passed through a 250�¼m sieve. The maximum optimized ratio (85:5.5:100) determined by DOE was chosen for further analysis. DSC, XRD, SEM were carried out to determine physicochemical changes after melt granulation. The granules were characterized for particle size analysis, flow properties, granule strength. Tablets containing 500 mg paracetamol and 200 mg ibuprofen were compressed at 10.0kN compaction force. The tablets were characterized for tablet hardness, friability, disintegration time and dissolution study. All results were found to be within acceptable USP limits. The optimized extruded batch was stable at 400C, 75%RH for a period of 6 months without changing any dissolution rate and remained into amorphous state.Biography

Email: moravkarkailas1985@gmail.com

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi