Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

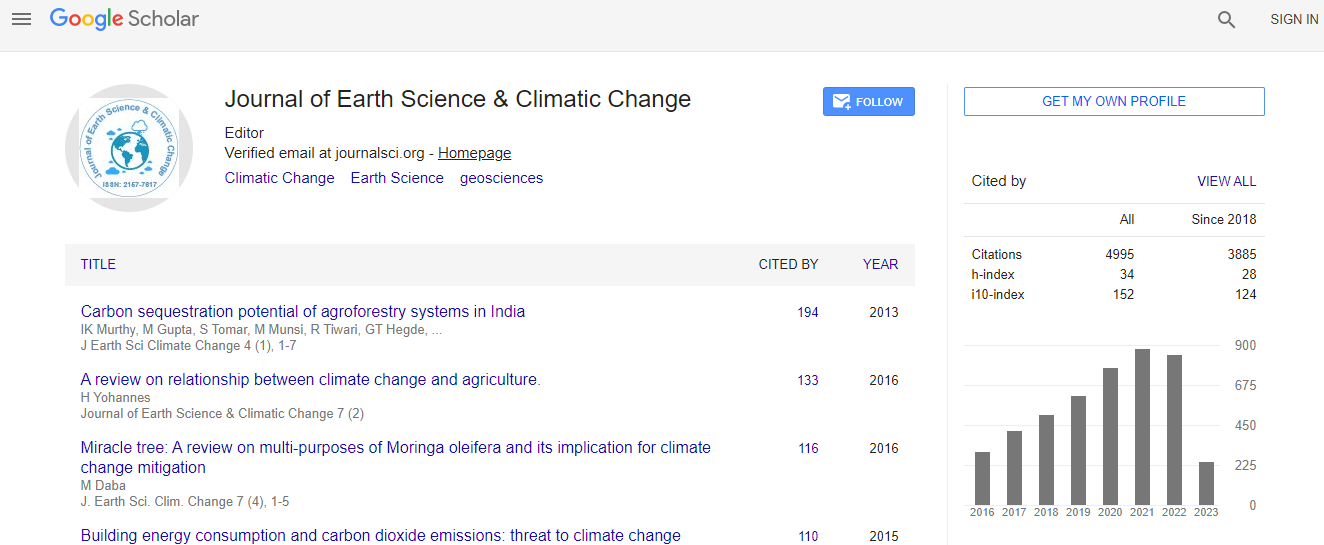

Google Scholar citation report

Citations : 5125

Journal of Earth Science & Climatic Change received 5125 citations as per Google Scholar report

Journal of Earth Science & Climatic Change peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Online Access to Research in the Environment (OARE)

- Open J Gate

- Genamics JournalSeek

- JournalTOCs

- Ulrich's Periodicals Directory

- Access to Global Online Research in Agriculture (AGORA)

- Centre for Agriculture and Biosciences International (CABI)

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Proquest Summons

- SWB online catalog

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

In Association with

Methodology for predicting internal fractures and relationship to grain geometry: Case study on low permeable core samples

2nd International Conference on Geology

Akshay A Thombare

Texas A&M University, USA

Posters & Accepted Abstracts: J Earth Sci Clim Change

Abstract

Selecting an ideal well or low permeable zone for fracturing has for long been a million dollar question. Limited understanding and sparse subsurface data many times dragged the focus of operators worldwide. To overcome the data gaps and to ease the decision making, the authors have undertaken a study to quickly predict the properties of cores. The objective was to predict the internal microfracture using conventional, simple geometrical technique and fracture mechanics. Several experiments were conducted on the core plugs of a low permeability sandstone and shale formation. The fracture was created using the universal testing machine with the help of core sleeve and then tested for prediction. Around 30 sidewall core samples of a sandstone formation was used for testing, density 2.65-2.67 gm/cc, having different permeability and porosity. The microscopic study was conducted to analyze grain geometry of the core sample. The ultimate aim is to compare and predict the grain geometry and internal fracture; The patterns and observations are then statistically classified. Subsequent experiments for predicting fracture connectivity had been undertaken using dye and imprinting it on a paper by rolling. Such paper imprints were analyzed to predict fracture connectivity (though tortuous). These experiments are a new concept in the petroleum industry and these experiments had substantially helped in predicting fracture orientation. Further refinements are definitely needed. However author��?s views are discussed in this paper. The results of the research showed that this techniques may be used to predict the internal fracture in a sandstone and shale core sample. It has also been inferred with higher certainty that the grain geometry can be classified and it has directly affected the fracture pattern. This technique will help to understand the direction of minimum horizontal stress which is the most important factor in designing the fracturing job. Since this methodology was applied to low permeability sandstone and shale formation there is further scope to validate it on a wider range of other rock types. This method may reduce uncertainty by great extent and may support a paradigm shift in exploiting low permeable formations.Biography

Email: thombare.akshay@gmail.com

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi