Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

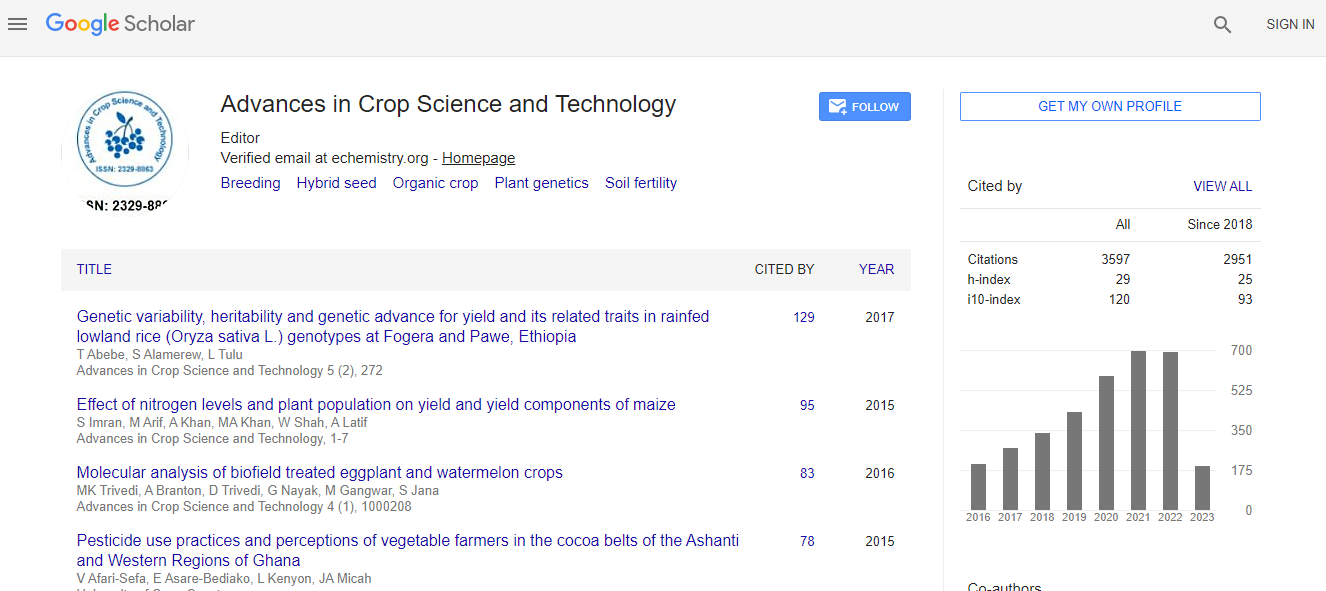

Google Scholar citation report

Citations : 5759

Advances in Crop Science and Technology received 5759 citations as per Google Scholar report

Advances in Crop Science and Technology peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Online Access to Research in the Environment (OARE)

- Open J Gate

- Academic Keys

- JournalTOCs

- Access to Global Online Research in Agriculture (AGORA)

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Impact of dehydration by successive pressure drops on specialty coffee

11th World Congress on Plant Biotechnology and Agriculture

Francy Vanegas, Sara V Noel, Rafael L Sandoval, Alfonso Parra and Sebastian Gutierrez

National University of Colombia, Colombia

ScientificTracks Abstracts: Adv Crop Sci Tech

Abstract

The dehydration process reduces the water content of a product to preserve for a long time. However, dehydration operation could carry out oxidation, undesired chemical reaction and loss of quality. In the case of the specialty coffee beans, to keep its volatile components, it is not advisable to dry it over 40�° C. This condition involves the development of new techniques, not only to improve the drying kinetics, also to obtain products with good properties. The dehydration by successive pressure drops (DPD) is a drying system which uses a repetition of compression and decompression cycles, DPD is slightly new for the heat sensitive products, but it had not still been used with the specialty coffee beans. The aim of this work is to define a methodology to evaluate the operation conditions on the DPD system over the drying rate (g H2O/kg coffee per h) for specialty coffee. Central Composite Design (CCD) was used to evaluate the two important operation factors of dehydrator: vacuum time and atmospheric pressure time. In conclusion, this methodology allows restrict the operation region to coffee drying. Along the experimental process, a pre-drying treatment was made to establish a uniform initial moisture content. After that, coffee beans were dried by DPD, with a vacuum pressure time of 13s and atmospheric pressure time 3s, over environmental temperature (15-20 �°C). It is necessary to take into account that another response variable could be adopted as grain degradation, organoleptic quality or porosity. Also, response surfaces from different variables could be combined to obtain not only the optimization of drying kinetics, but product with attractive properties for the consumer.Biography

Francy Vanegas is an Agricultural Engineering student at National University of Colombia. She has participated in 12th Latin American Congress of Agricultural Engineering with the article “Effect of different packages on mango quality (Mangifera Indica L.) sugar variety” and 7th Latin American Congress of Agricultural Engineering Students with the article “Behavior of Compression on altered and unaltered sols at different depths”.

Email:favanegasi@unal.edu.co

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi