Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

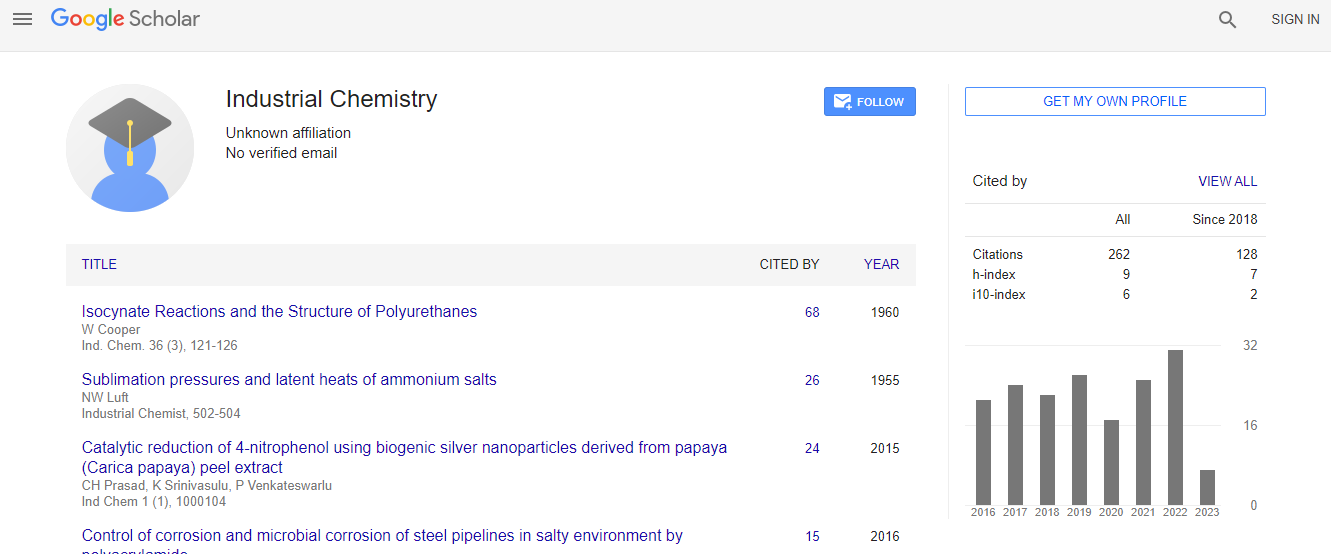

Google Scholar citation report

Citations : 262

Industrial Chemistry received 262 citations as per Google Scholar report

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Failure analysis of fiber reinforced plastics light pole

International Conference on Industrial Chemistry

M Bassyouni S M, S Abdel-hamid, M H Abdel-Aziz, Umair Javaid, Syed ulHasan and M Sh Zoromba

King Abdulaziz University, Saudi Arabia Higher Technological Institute, Egypt Port Said University, Egypt Alexandria University, Egypt

ScientificTracks Abstracts: Ind Chem

Abstract

In this study, failure analysis of light pole made of fiber reinforced plastics (FRPs) was investigated. The anisotropic properties of FRPs are advantageous in road accidents where these poles save valuable lives undergoing fragile failure. Chemical structure of FRPs light pole was studied using FT-IR. Samples of light pole were tested using dynamic mechanical analysis (DMA) and thermogravetric analysis (TGA) to study the viscoelastic and thermal stability properties respectively. Materials selection for wind load conditions was studied using Cambridge Engineering Selector (CES) program. FT-IR analysis refers to the presence of glass fiber, polyester (PE), natural fiber, coupling agent (N (beta-aminoethyl) gamma aminopropyltrimethoxysilane). It is found that glass transition temperature (Tg) of PE composite is 76.2 oC as the peak of loss modulus using DMA. Weight percent of glass fiber represent 40% of the total FRPs according to TGA. CES software results showed that the glass fiber ΓΆΒ?Β? PE composites are valid for light pole manufacture based on material index and wind load with safety factor 4. Delamination of FRPs was detected. This can be attributed to weak interfacial force among glass fiber and polyester in the presence of natural fiber. Hydrolytic breakdown of fiber matrix interface was formed due to presence of moisture (high humidity). This led to loss in performance efficiency of light pole made of FRPs.Biography

M Bassyouni has completed his PhD from Cairo University (Eperimental work was carried out at TU-Clausthal-Germany) and Postdoctoral studies from TUClausthal, Germany. He is the Head of Chemical and Materials Engineering Department, King Abdulaziz University, Rabigh-Saudi Arabia. He has published more than 45 papers in reputed journals and conferences. He has co-authored two books. He has been serving as an Editorial Board Member of International Institute of Chemical, Biological and Environmental Engineering.

Email: mbassyoni@kau.edu.sa.edu

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi