Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

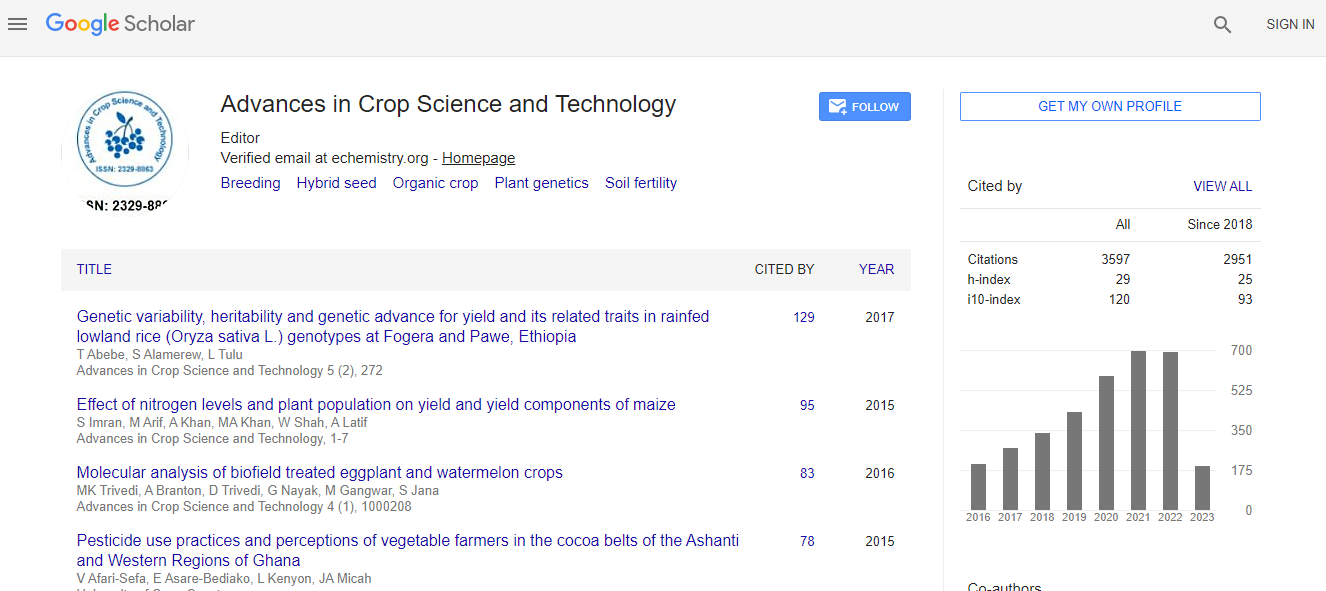

Google Scholar citation report

Citations : 5759

Advances in Crop Science and Technology received 5759 citations as per Google Scholar report

Advances in Crop Science and Technology peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Online Access to Research in the Environment (OARE)

- Open J Gate

- Academic Keys

- JournalTOCs

- Access to Global Online Research in Agriculture (AGORA)

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- SWB online catalog

- Publons

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Design and construction of a dehydrator by instant controlled pressure drop (ICPD) for specialty coffee

11th World Congress on Plant Biotechnology and Agriculture

Andres Felipe Gonzalez Mora, Adriana Meneses-Suarez, Jose Gamboa-Gamboa, Sebastian Gutierrez-Pacheco and Alfonso Parra-Coronado

National University of Colombia, Colombia

ScientificTracks Abstracts: Adv Crop Sci Tech

Abstract

The specialty coffee represents 12% above the consumption of coffee in the world. This product is characterized by the flavors given by certain microclimate, besides to achieve the stringent quality control. Therefore, it is necessary to carry out the techniques that optimize the process related to coffee conservation. Nevertheless, the conventional coffee drying does not allow a quickly and uniform process, affecting the grain quality and beverage characteristics. This work presents the design, construction and evaluation of a coffee dehydrator by instant controlled pressure drop (ICPD). The setup is composed by a treatment chamber, vacuum pump, control devices for the pressure drops and an electrical heater to transfer warmth through the coffee mass (1 kg) disposed inside the treatment chamber. To evaluate the process, the drying kinetic of coffee (Coffea arabica) was considered. Factorial design 32 was adopted, taking as factors the coffee origin (Nari├?┬?├?┬▒o, Cundinamarca and Sierra Nevada) and the wet processing coffee phases (cherry, mucilaged and parchment coffee). The conception considered that high frequency and major difference of pressure represent major air flow through the treatment chamber, ensuring an improvement in the drying kinetic. The design was made to experimental specialty coffee drying, but the setup could be adapted and scaled to dehydrator for other products.Biography

Andres Felipe Gonzalez Mora is a Researcher at National University of Colombia. He has knowledge in postharvest and storage of grains and fruits, modeling and simulation of drying process and biosystems control. In addition, he has experience in research projects about storage methods of mango (Mangifera indica).

Email:andfgonzalezmor@unal.edu.co

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi