Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

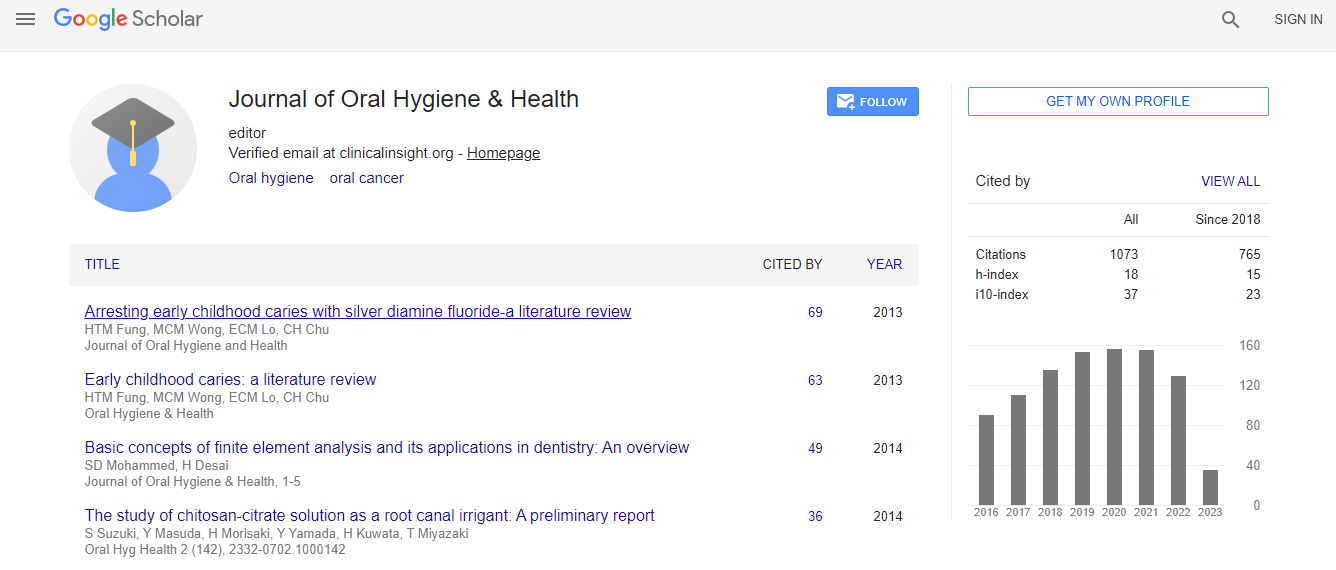

Google Scholar citation report

Citations : 1073

Journal of Oral Hygiene & Health received 1073 citations as per Google Scholar report

Journal of Oral Hygiene & Health peer review process verified at publons

Indexed In

- Index Copernicus

- Google Scholar

- Open J Gate

- JournalTOCs

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Comparison of the internal and marginal adaptation of metal substructures fabricated by different manufacturing techniques

2nd International Conference on Restorative Dentistry and Prosthodontics

Nazli Yesilyurt Aydin, Yurdanur Ucar and Orhun Ekren

Cukurova University, Turkey

ScientificTracks Abstracts: J Oral Hyg Health

Abstract

Using computer aided methods, a final object can be manufactured either by milling from a block or additive manufacturing which allows standard object production with low cost and decreased manufacturing time. The aim of the study was to compare the internal and marginal fit of crowns fabricated using conventional casting, laser sintering and soft-metal milling. A first maxillary molar die made of metal was fabricated. Metal substructures with standardized sizes were manufactured using conventional casting, laser sintering and soft-metal milling (N=15/group). Internal-fit and marginal-fit of metal substructures were evaluated. The metal substructures were seated on the metal die using light body silicone material. Excess silicone was cleaned. Following the setting, crowns were removed and silicone was weighed to evaluate the 3D internal cement gap. Same specimens were used for marginal gap measurements under a light microscope. Statistical analysis was performed using one-way ANOVA followed by Tukey HSD test (�±=.05). A statistically significant difference was observed for both internal and marginal fit among compared groups (p<0.05). The highest mean silicone weight (standard error) was observed in casting group (36.8�±1.9 mg) followed by laser sintering (26.6�±1.5 mg) and soft-metal milling (20.7�±1.4 mg) groups. The lowest mean marginal gap (standard error) was observed in laser sintering group (4.2�±1.2 �¼m) followed by casting (8.7�±1.2 �¼m) and soft-metal milling (22.3�±1.2 �¼m) groups. Although statistically significant differences were observed among all compared groups, a clinically significant difference canâ��t be mentioned.Biography

Nazli Yesilyurt Aydin has completed her license in 2013 from Marmara University, College of Dentistry. She is currently enrolled in a Specialty Program in Department of Prosthetic Dentistry at Cukurova University.

Email: nyesilyurt@cu.edu.tr

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi