Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

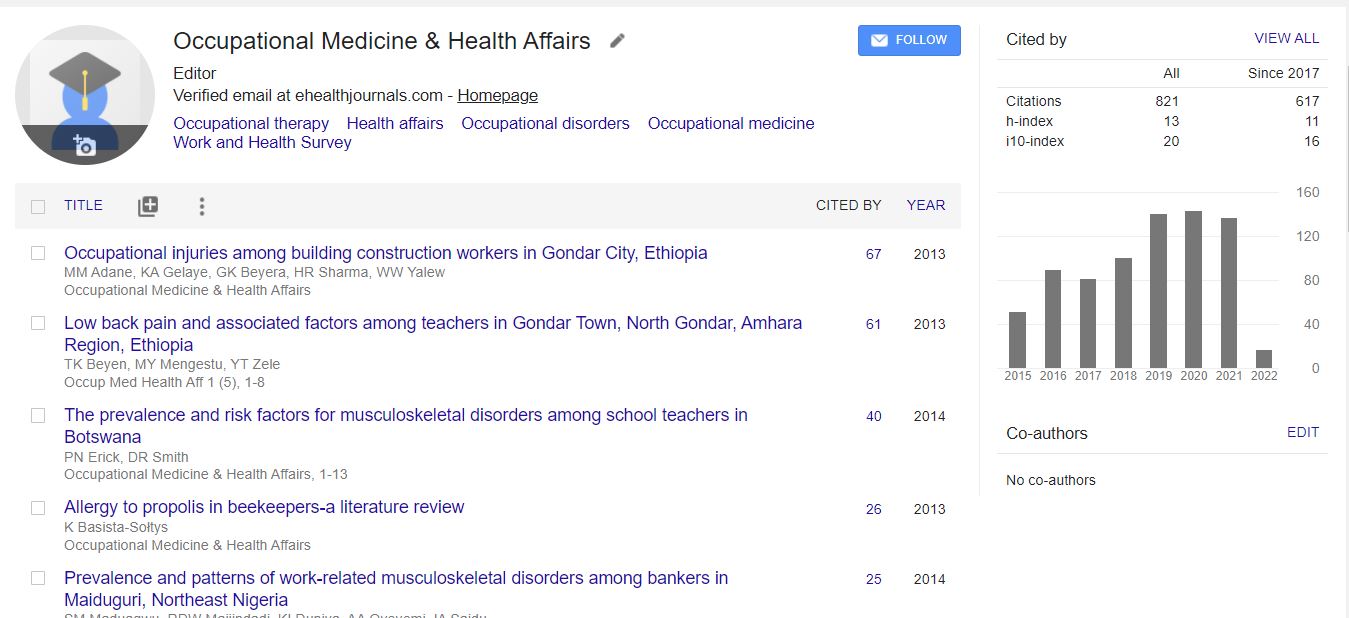

Google Scholar citation report

Citations : 1907

Occupational Medicine & Health Affairs received 1907 citations as per Google Scholar report

Indexed In

- Index Copernicus

- Google Scholar

- Open J Gate

- Academic Keys

- China National Knowledge Infrastructure (CNKI)

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Geneva Foundation for Medical Education and Research

- Euro Pub

- Geneva Foundation for Medical Education and Research

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Autospare Parts Manufacturing Analysis in terms of Occupational Health and Safety

9th International Conference on Occupational Health and Public Safety

Dilay AKGUL,Labor Expert

Ministry of Labour and Social Security, Directorate General of Occupational Health and Safety

ScientificTracks Abstracts: Occup Med Health Aff

Abstract

Statement of the Problem: This thesis aims to determine risks which cause work accidents and occupational diseases belong to auto spare parts production sector and identify reasons of those risks and provide solutions for them. On the other hand, rational recommendations will be presented according to results obtained by applying necessary measurement analysis on the sources of chemical exposures which are determined in the mentioned sector. In the study, risks and sources of hazards are examined five sections in the production and storage line in which contains only the processes of metal and plastic operations as raw material in five auto spare parts manufacturing plants in Turkey. Methodology & Theoretical Orientation: Within the scope of the study, hazard and risk analyzes were made and checklists were created in the production and storage lines where 2494 workers work. Moreover, in order to determine chemical exposure; dust, fibrous dust, heavy metal and aromatic hydrocarbon measurements are applied in two different plants selected from among five. To this end, in the context of the study, hazards are examined under the title of mechanical, physical, chemical hazards, also electrically welded fire and explosions in the field of auto spare parts plants; and risks arising from those dangers are identified. It was determined that chemical exposure values differ according to methods of production, production rate, used raw materials and their portion size, the ventilation system and used gasoline vehicles in the environment, used machinery and positioning of benches. Risks that arise from mentioned hazards and solution suggestions are also presented as tables. According to the tables, sector-specified checklist in 9 different section which can be used in auto spare parts production was prepared. Recent Piblications 1. Jacob T.R, Hadley J.G, Bender J.R, Eastes W, Airborne glass fiber concentrations during manufacturing operations involving glass wool insulation. The American Industrial Hygiene Association Journal, 54(6);320-326, 1993. 2. Hunting K, Welch L, Occupational Exposure to Dust and Lung Disease Among Sheet Metal Workers, British Journal of Industrial Medicine,50(5); 432-442, 1993 3. Kondej D, Sosnowski T, The Influence Of Metal-Containing Occupational Dust On Pulmonary Surfactant Activity, Chemical Engineering Transactions, 19(3); 315-320, 2010 4. Vitali M, Ensabella F, Stella D, Guidotti M, Exposure to organic solvents among handicrafts car painter: a pilot study in Italy, Industrial Health, 44(2); 1-8, 2006 5. Bylund P.O, Bj�¶rnstig U, Occupational injuries and their long term consequences among mechanics and construction metal workers, Safety Science Journal, 28(1) ; 49-58, 1998.Biography

In the Occupational Health and Safety Research and Development Institute (ISGÜM), I worked in the Occupational Hygiene Chemical Factors Unit between 2012-2017. Along with the endorsement of the agreement signed by ILO and Turkey Republic, Occupational Health and Safety Center (ISGUM) was established under the Directorate General of Labour Health with number in 1969 decision of Council of Ministers. I have the competence to use the following laboratory devices for analyzes to detect chemical factors in the workplace environment. Since 2017, I have been continuing my service as a specialist in ISGÜM Training and Organization unit. I have been responsible of the planning, recording, organizing the ILO International Classification of Pneumoconiosis Radiographs Reader Education and Asbestos Removal Specialist Training. With my team, initiation of purchasing processes, training records, communication and coordination with participants and trainers, implementation of training evaluation surveys, evaluation, and reporting of surveys, supporting national and international projects. Projects run by me in ISGÜM; •Development and Dissemination of Distance Education in the Field of OHS Project, Investment Project of Turkey Republic (2021-2022) •IPA III- Organized cooperation for promotion of occupational health and safety in SMEs. (in the approval process)

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi