Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

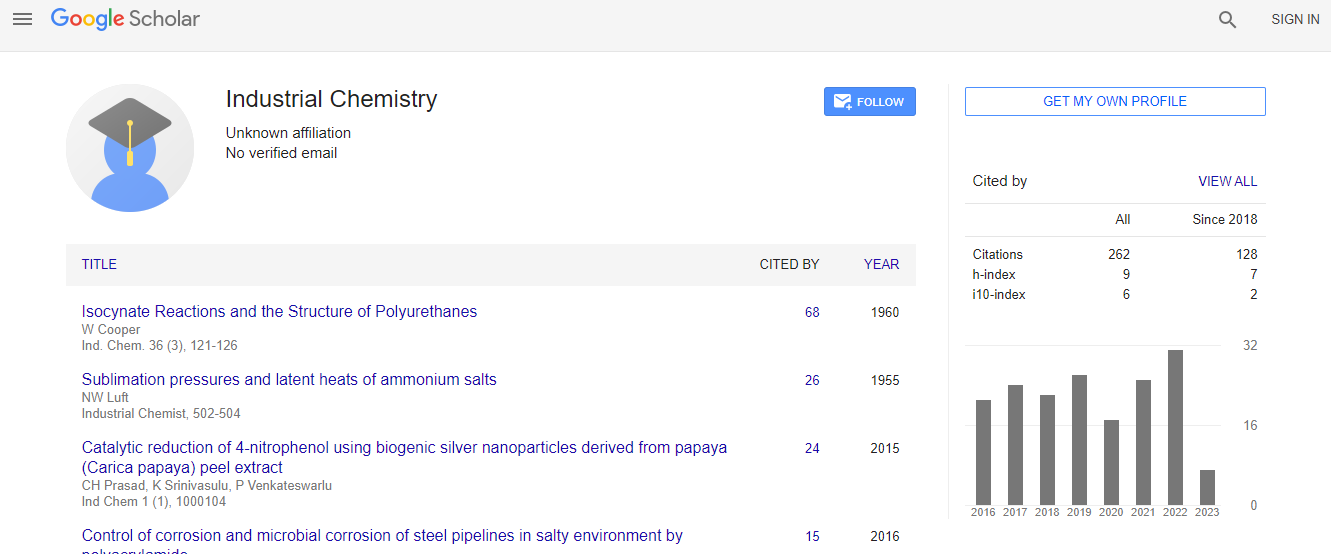

Google Scholar citation report

Citations : 262

Industrial Chemistry received 262 citations as per Google Scholar report

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Application of FeCl3 and Fe(OH)3 compounds for comprehensive silica removal facilitating zero liquid discharge in RO and IC waste water reuse

2nd World Conference on Industrial Chemistry and Water Treatment

Ehren D Baca, Jr L Lin and Kerry J Howe

University of New Mexico, USA Chung Yuan Christian University, China

Posters & Accepted Abstracts: Ind Chem

Abstract

Chemical mechanical planarization (CMP), used heavily in integrated circuit (IC) manufacture, generates copious amounts of waste water high in colloidal and reactive silica, which inhibits on-site reuse in cooling operations and ultra-pure water (UPW) production. Silica, when present in cooling water, can reach solubility limits via evaporation and form impervious scale on heat transfer surfaces that decreases efficiency. Silica in reverse osmosis feed-water inhibits aspirations for high rejection and zero liquid discharge (ZLD) due to scale formation. When subjected to RO at high rejection, silica forms difficult-toremove scale on the membrane concentrate side in the form of glassy patches and communities of aggregate particles. Current methods for silica scale mitigation in industry include dosing with chemical anti scalents or complex operating schemes including ion exchange and large pH swings. This work evaluates the implementation of the common chemical coagulant, FeCl3 and highly insoluble Fe (OH)3 in the removal of silica by coagulation and adsorption mechanisms, respectively. FeCl3 was shown to be optimizable for silica colloid coagulation in CMP waste water via charge neutralization resulting in turbidity <10NTU. Adsorption of reactive silica on Fe (OH)3 using a sequencing batch reactor approach exhibited >90% silica removal for the first adsorption cycle, and increased utilization of adsorbent material for subsequent runs in both CMP waste water and RO concentrate.Biography

Email: ebaca20@unm.edu

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi