Our Group organises 3000+ Global Conferenceseries Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ Open Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

Open Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

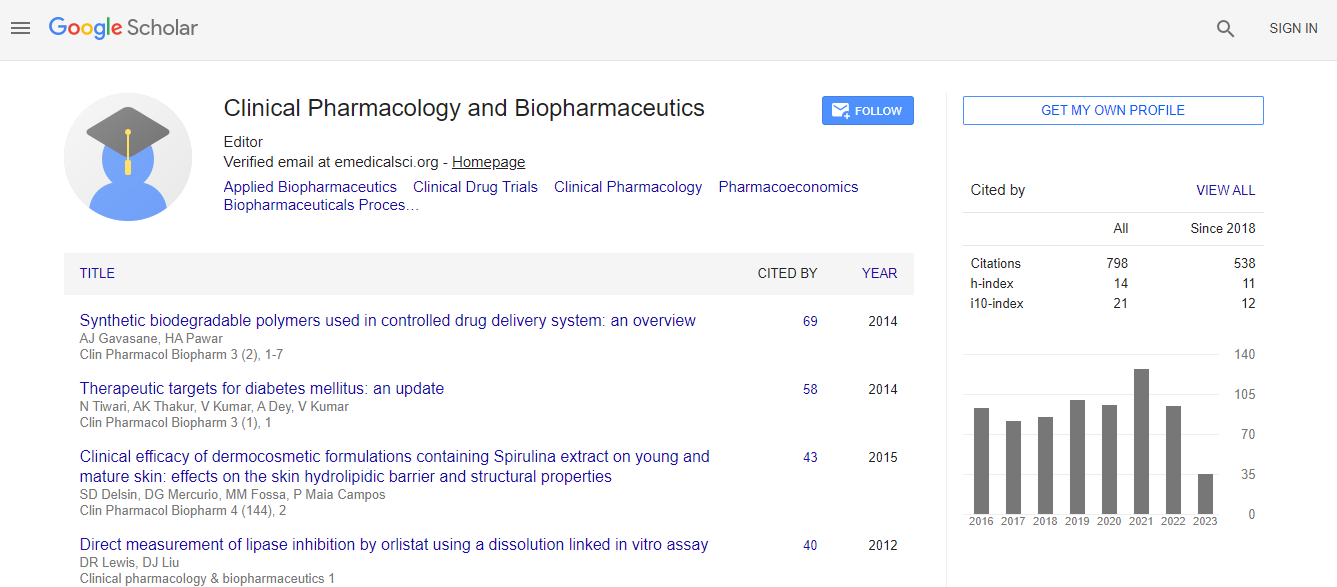

Google Scholar citation report

Citations : 1089

Clinical Pharmacology & Biopharmaceutics received 1089 citations as per Google Scholar report

Clinical Pharmacology & Biopharmaceutics peer review process verified at publons

Indexed In

- CAS Source Index (CASSI)

- Index Copernicus

- Google Scholar

- Sherpa Romeo

- Genamics JournalSeek

- RefSeek

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Publons

- Euro Pub

- ICMJE

Useful Links

Recommended Journals

Related Subjects

Share This Page

Achieving Quality by Design for parenterals filling with a time-pressure setup

Joint Event on 4th European Biopharma Congress & 6th International Conference and Exhibition on Pharmacology and Ethnopharmacology

Yannick Elias

Janssen (Cilag AG), Switzerland

ScientificTracks Abstracts: Clin Pharmacol Biopharm

Abstract

Particulate matter in parenteral drug products is recognized by Health Authorities as a critical quality attribute. A strong focus of fill and finish process development is put on the appropriate selection and operation of the filling system to reduce intrinsic particle formation, often related to shear induced drug product degradation. Rotary Piston Pumps (RPP) have been a standard selection in Janssen for many years, as they offer a simple, compact and robust design and show a very high dosing accuracy. However, as the drug product acts as a pump lubricant, the product is exposed to very high shear rates, which in turn can cause enhanced intrinsic particle formation. Thus, alternative filling technologies, such as peristaltic pumps (PP) or a time-pressure (TP) system, are required for shear-sensitive products. A TP system consists essentially of a pressurized tank and a pinch valve. Dosing accuracy is achieved by harmonizing the vessel over pressure and the valve opening duration. To improve the overall product quality during filling of shearsensitive products, a Quality by Design and Right the First Time approach is chosen to ensure proper equipment operation. For this, understanding the critical process parameters, risks associated with those parameters and their impact on critical product quality attributed is crucial. Thus, a Design of Experiment study was performed to identify and characterize the impact of six distinct process and equipment parameters on different solutions to obtain a Design Space for optimal TP filling operation.Biography

Yannick Elias completed his PhD from Swiss Federal Institute of Technology Zurich (ETH Zürich) in Process Engineering, focusing on continuous heterogonous reactions and has published several papers in reputed journals. Currently, he works for Janssen Pharmaceutical Development and Manufacturing Sciences (PDMS) as a Process Engineer, focusing on development for parenterals fill and finish operations. He worked with Janssen for more than one and a half years and is currently leading the strategic expansion of a large molecule drug product development laboratory.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi