Page 73

Biopolymers and Bioplastics 2016

September 12-14, 2016

Volume 7, Issue 5(Suppl)

J Bioremed Biodeg 2016

ISSN: 2155-6199 JBRBD, an open access journal

conferenceseries

.com

September 12-14, 2016 San Antonio, USA

3

rd

International Conference and Exhibition on

Biopolymers & Bioplastics

J Bioremed Biodeg 2016, 7:5(Suppl)

http://dx.doi.org/10.4172/2155-6199.C1.003Biodegradable poly(propylene carbonate)-based composite: An alternative biomaterial to polylactic acid

Fariba Dehghani

1

, Iman Manavitehrani

1

, Ali Fathi

1

, Yiwei Wang

1

and

Peter K Maitz

1,2

1

University of Sydney, Australia

2

Concord Repatriation General Hospital, Australia

P

oly(lactic acid) (PLA) and other polyester-based polymers are broadly used in biomedical applications due to their

favourable mechanical strength and biodegradable properties. However, the acidic properties of their degradation

products may lead to clinical complications, such as inflamation, long-term osteoporosis and other unpredictable issues. In

this study, we demonstrate the superior properties of the poly(propylene carbonate) (PPC)-starch composite as an alternative

to polyester-based biomaterials. The degradation products of PPC-starch are mainly carbon dioxide and water. Hence, the pH

in the surrounding tissues of an implant fabricted from this composite does not decrease. Moreover, the mechanical strength

of PPC-starch composites is tuneable within the range of 0.2±0.03 MPa to 33.9±1.51 MPa, by varying the starch content

from 0-50 w%. PPC-starch composites are cytocompatible as osteoblast cells adhere and proliferate on their surface within

seven days. The long-term biocompatibility of PPC-starch is assessed via subcutaneous implantation in mice. The results of

histological analysis demonstrate no symptom of inflammation for PPC-starch composite after eight weeks implantation, while

the biodegradation of PLA lead to massive immune cell infusion and inflammation. These results underline that PPC-starch is

suitable for biomedical applications and can be used for the musculoskeletal tissue regeneration.

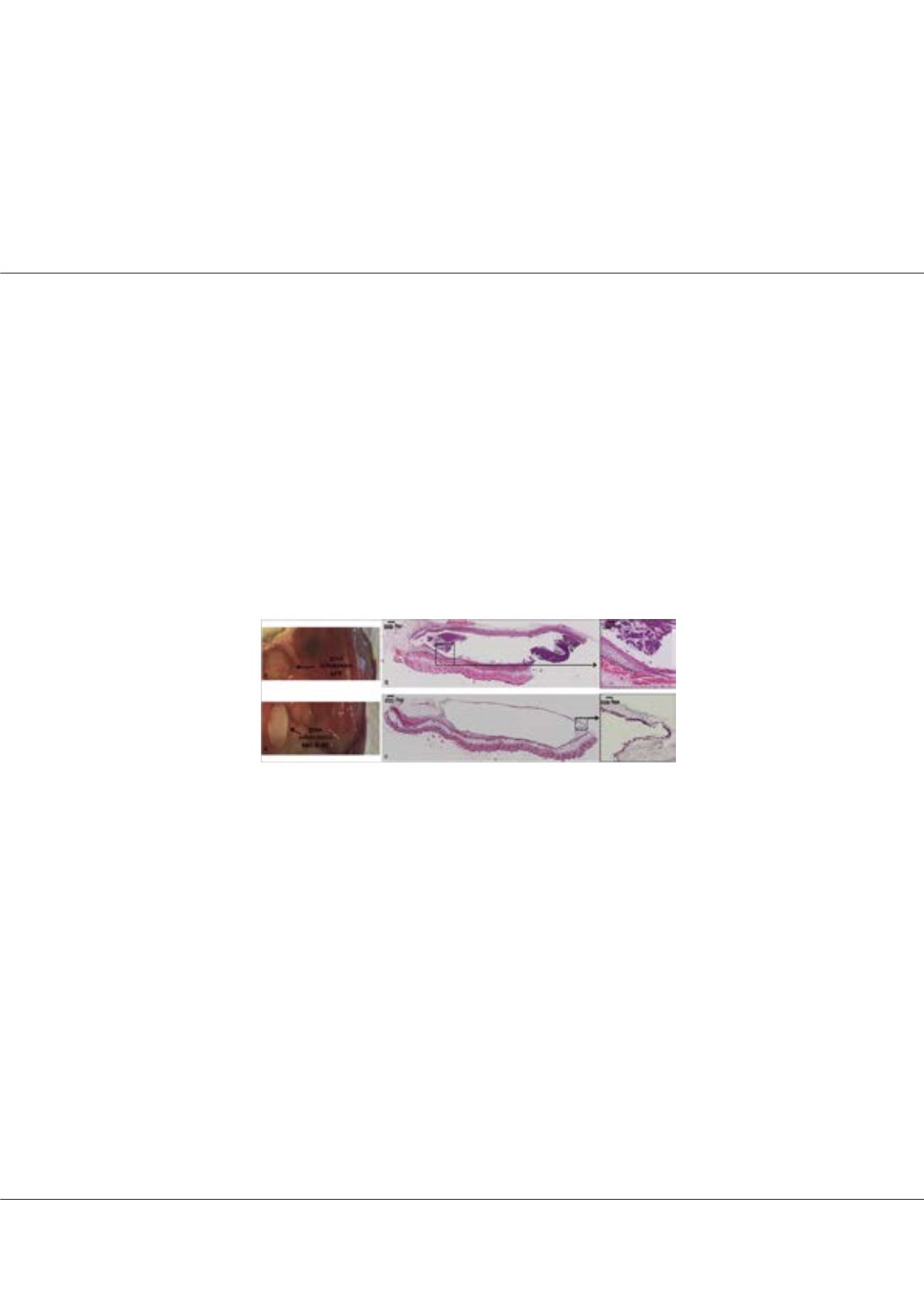

Figure 1: The explanation site of PPC-ST50 (a) and PLA (b) 8 weeks post-surgery, and haematoxylin and eosin staining of

paraffin sections of the implantation site at 8 weeks around PPC-ST50 composite (c) and PLA (d). After 8 weeks a prominent

foreign body reaction is observed around PLA implantation zone. However, the inflammatory response to the PPC-ST50

composite is resolved dramatically.

fariba.dehghani@sydney.edu.auPreparation of some chitosan derivatives and study of their effect on human genetic material

Hadi S Al-Lami, Sara H Mutasher

and

Afrodet A Salih

University of Basrah, Iraq

C

hitosan is a polycation biopolymer material. It has several applications, especially in the biopharmaceutical and biomedical

fields. Chitosan was produced from shrimp waste by chemical method involving demineralization, deproteinization and

deacetylation. It was characterized by intrinsic viscosity measurement and Fourier transform infra-red in order to determine

the average molecular weight and degree of deacetylation of purified chitosan. Chitosan was modified by grafting process

with maleic anhydride, poly(adipic anhydride) and poly(sebacic anhydride) to evaluate their effect on binding to the human

genomic DNA. The grafted chitosan derivatives appeared as promising materials to be used as a model for DNA and gene

delivery. Grafted chitosan-DNA complexes were determined by gel electrophoresis technique and ultraviolet spectroscopy.

hadisalman54@yahoo.com