Volume 7 Issue 6(Suppl)

J Bioremediat Biodegrad

ISSN: 2155-6199 JBRBD, an open access journal

Page 21

Bioplastics 2016

November 10-11, 2016

conference

series

.com

November 10-11, 2016 Alicante, Spain

International Conference on

Sustainable Bioplastics

Gadi Rothenberg, J Bioremediat Biodegrad 2016, 7:6(Suppl)

http://dx.doi.org/10.4172/2155-6199.C1.004Plantics: Plastics made from plants

H

ow often is it that you invent something that can truly change people’s lives and make the world a better place? We’ve

been working on catalyst discovery and development for bulk chemicals and sustainable energy for over a decade, and

during those years we found quite a few nice things, but nothing truly spectacular. And then, five years ago, we discovered by

accident a new type of biodegradable polymer made from 100% plant-based materials. It would be nice to say that this involved

years of study and preparation, but in fact we were just very lucky. This new plastic is inherently non-toxic and non-hazardous.

Excitingly, it is cheap enough to replace polyurethane and in some cases polypropylene and PET on a kilogram to kilogram

basis (see Figure 1). It is now being manufactured on ton scale by a spin-off company, Plantics BV, which is situated at the Port

of Amsterdam. During the scaling up and manufacturing we have found a host of new and exciting things. In the lecture, I will

tell you how we discovered this plastic, and discuss the pros and cons of making chemicals and polymers from biomass. I will

also show examples of this new type of plastics and share our stories

of trying to bring a new material into the conservative industrial

sectors of injection moulding, agro-products, building materials

and oil drilling additives.

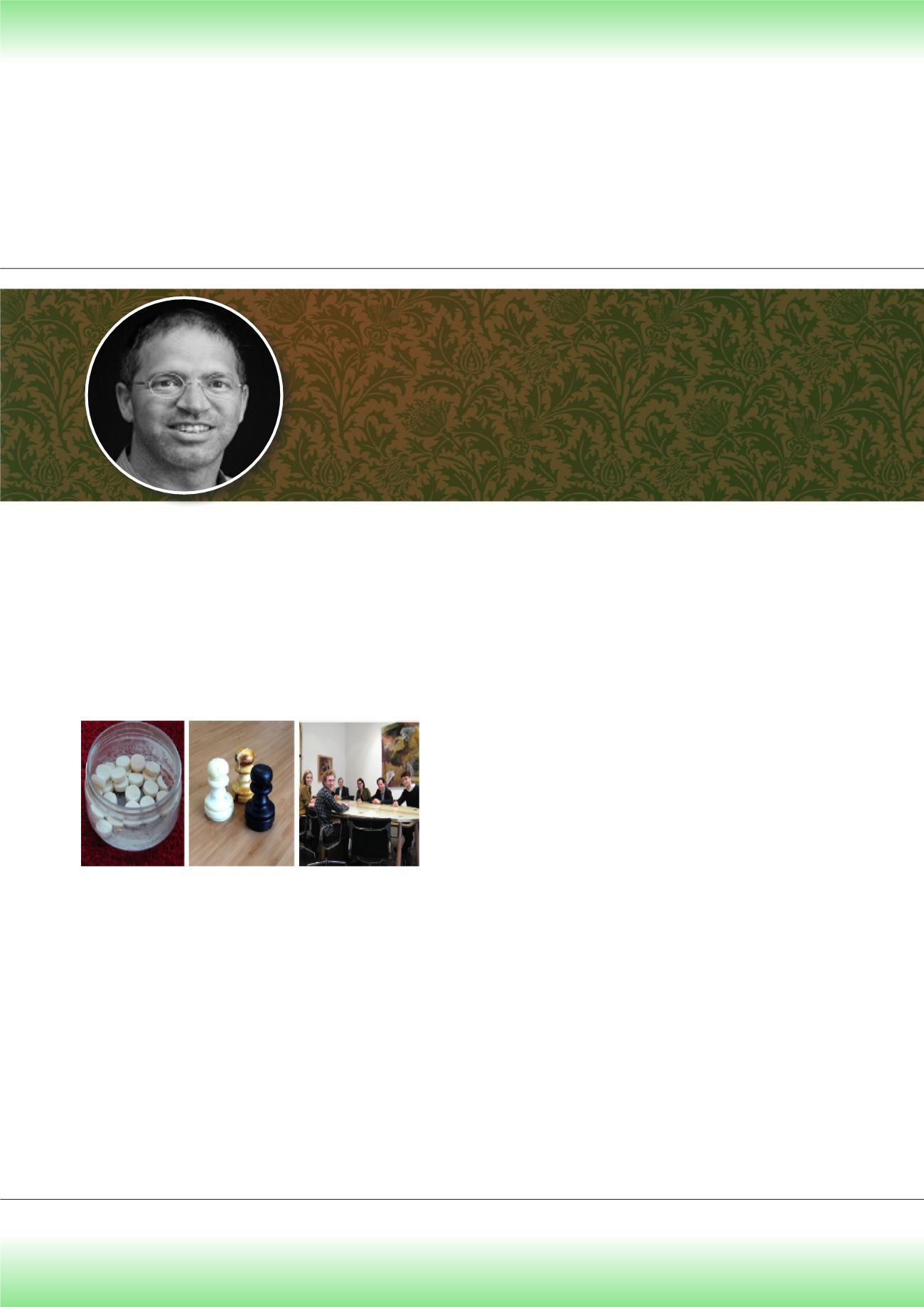

Figure 1. Left:

Pellets of our bioplastic that can be used in injection

moulding or compression moulding. Centre: solid chess pawns

pressed from the bioplastic (the black color is achieved by mixing 1

wt% of carbon black into the polymer mixture).

Right:

A conference table which was made from the bioplastic, in collaboration with product design students of the Amsterdam

University of Applied Sciences.

Biography

Gadi Rothenberg has obtained his BSc in Chemistry in 1993, and PhD in Applied Chemistry from the Hebrew University of Jerusalem in Israel in 1999. He was a

Marie Curie Fellow at the University of York (UK) and moved to the University of Amsterdam, where he is now a Professor and Chair of Heterogeneous Catalysis

and Sustainable Chemistry at the Van`t Hoff Institute for Molecular Sciences. He also teaches courses on catalysis, thermodynamics and scientific writing. He has

published two books and over 160 papers in peer-reviewed journals. His textbook “

Catalysis: Concepts & Green Applications

” is a Wiley-VCH bestseller. He has

also invented 15 patents, and co-founded the companies like Sorbisense A/S, Yellow Diesel BV and Plantics BV. His latest inventions are a new catalyst for cleaning

cyanide from wastewater and a metal-free super-capacitor material.

g.rothenberg@uva.nlGadi Rothenberg

University of Amsterdam, Netherlands