Page 60

Notes:

conferenceseries

.com

Volume 8, Issue 5 (Suppl)

J Bioremediat Biodegrad, an open access journal

ISSN: 2155-6199

Biofuels Congress 2017

September 05-06, 2017

September 05-06, 2017 | London, UK

Biofuels and Bioenergy

6

th

World Congress on

Biorefinery approach of microalgae feedstock for the production of bioethanol and biodiesel

Ramachandran Sivaramakrishnan

and

Aran Incharoensakdi

Chulalongkorn University, Thailand

T

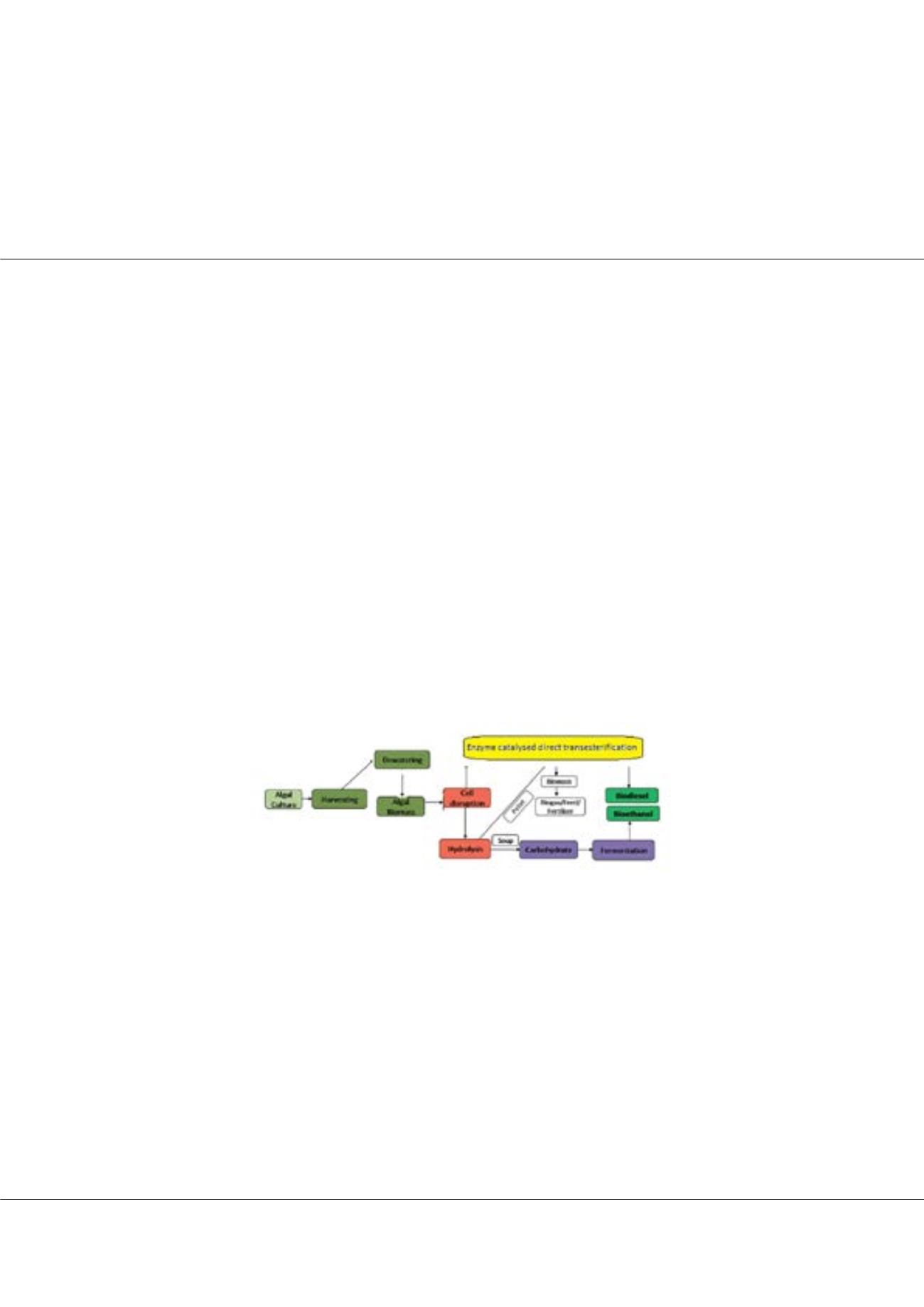

he continued use of fossil fuels depletes the reserves; more than 75%of petroleumbased fuels are burnt in the transportation

sector. The utilization of global energy is expected to be increased in the future due to increased population and demand.

Therefore, there is a need for alternative fuel, which is not only satisfying the need, but also solving the environmental

problems. Microalgae feedstocks, a reliable biofuel source, have drawn much attention as an alternative and renewable. This

is due to the microalgal species have the excellent photosynthetic efficiencies and the biomass reproducibility potential than

any other terrestrial crops. In this study the integrated approach of ethanol and biodiesel production from algal biomass has

been proposed. This integrated method is to develop the microalgae based biorefinery model. The present study focuses on the

biorefinery approach of integrated production of bioethanol and biodiesel from microalgae feedstock. Various pretreatment

methods were used to determine the maximum recovery of sugars from

Scenedesmus

sp. The total sugar yield of 84% was

obtained when pretreated separately by acid hydrolysis. The hydrolysate produces 90% of ethanol (theoretical yield) after the

fermentation. Enzyme catalyzed ultrasound assisted direct transesterification of biomass was performed and the maximum

of 91% methyl ester yield, 2.6% glycerol carbonate and 5.6% glycerol dicarbonate was obtained. The integrated process of

initial acid hydrolysis produces 84% of total sugar. The sugar extracted biomass was initiated with enzyme catalyzed direct

transesterification with ultrasound irradiation. The obtained hydrolysate was further fermented with S. cerevisiae and at the

optimized conditions of fermentation 90%of ethanol (theoretical yield) was obtained.The conditions of direct transesterification

using enzyme were optimized and produces 89% of biodiesel yield with 2.1% glycerol carbonate and 4.9% glycerol dicarbonate.

Thus, the microalgal biomass efficiently produces both ethanol and biodiesel as well glycerol carbonate, which could be the

biorefinery model for sustainable future development.

Biography

Ramachandran Sivaramakrishnan has been working in the production of biofuels from microalgae. He is working as a Post-doctoral researcher in the Department

of Biochemistry, Chulalongkorn University. His Doctoral studies were about methyl ester production from macroalgae using lipase catalyst. He has been awarded

as Junior Research Fellow by Department of Science and Technology, India. He has published five research articles in international journals.

rsrkbiol@gmail.comRamachandran Sivaramakrishnan et al., J Bioremediat Biodegrad 2017, 8:5(Suppl)

DOI: 10.4172/2155-6199-C1-008