Page 41

conferenceseries

.com

Volume 8

Journal of Fundamentals of Renewable Energy and Applications

ISSN: 2090-4541

Battery Tech 2018

September 10-11, 2018

September 10-11, 2018 | London, UK

3

rd

International Conference on

Battery and Fuel Cell Technology

Materials development for advanced Li ion batteries

Margret Wohlfahrt-Mehrens

ZSW, Germany

L

ithium ion batteries are widely used in many portable applications and are the most promising energy storage systems

for future mobility and stationary applications. Worldwide, extensive research efforts focus on the development of high

performance, low cost and more sustainable materials for advanced lithium ion batteries. In this presentation, we describe

various strategies to increase the energy density of lithium ion batteries by combining high voltage and high capacity cathode

materials as nickel rich layered oxides or high voltage spinel type materials with silicon/carbon composites. An alternative

approach is the development of cobalt free cathode materials. Co-free, Li-rich Li

1+x

Ni

0.5

Mn

1.5

O

4

(0<x<1) compounds are

very promising candidates for high energy applications. The lithium‐nickel‐manganese oxide compounds can be tailored

with respect to composition in order to reach high capacities up to 250 mAh g

-1

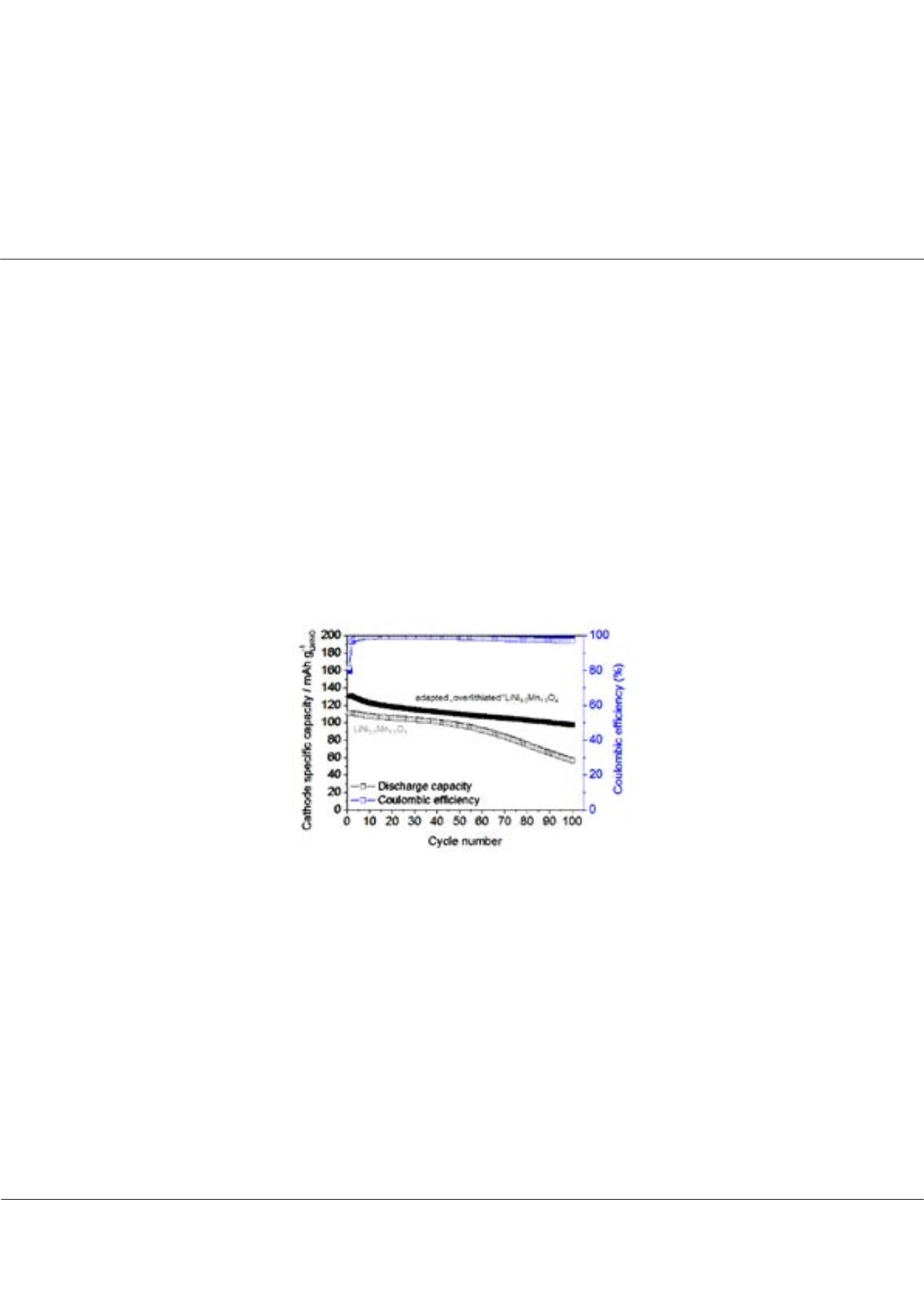

with long cycling life. An adapted electrode

manufacturing process including a deep understanding of the interactions between powder properties, process parameters

and electrochemical performance is essential to get maximum cell performance. In addition, lithium plating can occur during

charging, which is a severe ageing mechanism and a potential safety risk. Adapted cathode materials with excess of lithium can

be used to compensate irreversible losses of silicon based anode materials and to prolong life time in full cells.

Figure 1

: Capacity retention of two Li ion cells Si//LiNi

0.5

Mn

1.5

O

4

(open squares) and Si//Li

1+x

Ni

0.5

Mn

1.5

O

4

with excess lithium adapted to irreversible loss of silicon (black

squares); capacity is referred to cathode material.

Recent Publications

1. M Marinaro, MWeinberger and MWohlfahrt-Mehrens (2016) Toward pre-lithiatied high areal capacity silicon anodes

for Lithium-ion batteries, Electrochimica Acta 206:99-107.

2. G Gabrielli, P Axmann, T Diemant, R J Behm and M Wohlfahrt‐Mehrens (2016) Combining optimized particle

morphology with a niobium‐based coating for long cycling‐life, high‐voltage lithium‐ion batteries. ChemSusChem

9(13):1670-1679.

3. M Mancini, G Gabrielli, P Axmann and M Wohlfahrt-Mehrens (2017) Electrochemical performance and phase

transitions between 1.5 and 4.9 V of highly-ordered LiNi

0.5

Mn

1.5

O

4

with tailored morphology: influence of the lithiation

method. Journal of the Electrochemical Society 164(1):A6229-A6235.

4. T Waldmann, B I Hogg and M Wohlfahrt-Mehrens (2018) Li plating as unwanted side reaction in commercial Li-ion

cells–A review. Journal of Power Sources 384:107-124.

Margret Wohlfahrt-Mehrens, J Fundam Renewable Energy Appl 2018, Volume 8

DOI: 10.4172/2090-4541-C5-062