Research Article Open Access

Using the Advanced Analytical Techniques to Investigating the Versatile Cellulosic Graft copolymers

Ashish Chauhan* and Balbir Kaith

Department of Chemistry, Dr. B.R.A. National Institute of Technology, Jalandhar, India

- *Corresponding Author:

- Ashish Chauhan

Jr. Scientist

Department of Chemistry

Dr. B.R.A. National Institute of Technology

Jalandhar - 144011, Punjab, India

E-mail: aashishchauhan26@gmail.com

Received date: July 27, 2012; Accepted date: September 20, 2012; Published date: September 27, 2012

Citation: Chauhan A, Kaith B (2012) Using the Advanced Analytical Techniques to Investigating the Versatile Cellulosic Graft copolymers. J Anal Bioanal Tech 3:146. doi: 10.4172/2155-9872.1000146

Copyright: © 2012 Chauhan A, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Journal of Analytical & Bioanalytical Techniques

Abstract

In this research paper, the cellulose rich biomass of Sorrel was graft copolymerized by vinyl monomeric mixtures. The graft copolymers were characterized by advanced analytical techniques like FTIR, SEM, XRD, TGA and DTA techniques and evaluated for physico-chemical changes in the properties of the modified fiber. With increase in the percentage grafting a significant physico-chemico-thermal resistance were observed. Miscibility in organic solvents, hydrophobicity were found to increase whereas crystallinity, crystallinity index, dye-uptake and hydrophylicity decreased after graft copolymerization, however, the cellulose form I remained unchanged. These graft copolymers were then used as reinforcement in phenol-formaldehyde polymer matrix based green composite. They were then characterized and evaluated for their physico-chemico-thermo-mechanical competence. The use of graft copolymers as reinforcement in polymer matrix is the best technique to procure green composite. The novelty of the work lies in the use of renewable waste biomass to procure the advanced material. These advanced materials could serve as pioneer for scientific and industrial applications.

Keywords

Hibiscus sabdariffa; Graft copolymerization; Chemical resistance; Thermal resistance

Introduction

Natural fibers and polymer are of immense use for the mankind. The whole world has focused its attention towards renewable and sustainable resources because of environment and health concerns. Many efforts have been made to explore the maximum potential of renewable resources. The development of new polymer from renewable raw materials in comparison to artificial fibers has been increased during last few years. Natural fibers like pine needle, flax, jute and ramie are the most suitable reinforcement materials because of their relatively high strength and stiffness in industries such as automobile, packaging and construction materials, to match their economic and ecological aspects [1-4]. Low cost, easily availability and required properties (viz. low density, mechanical properties) makes them attractive in place of glass, carbon and other synthetic fibers. The constituents of natural fibers are cellulose, hemicelluloses, lignin and pectins with a small quantity of the extractives. The properties of bio-fibers mainly depend upon their origin, age, climatic conditions and extraction techniques. The presence of hydroxyl groups (polar group) in various constituents of lingo-cellulosic fiber reduces the utilities in many applications [5- 12]. In order to improve it adhesion, various techniques like graft copolymerization, chemical treatment (mercerization, acetylation, benzoylation etc.,) and treatment with various coupling agent can be used.

Graft copolymerization is an efficient technique to impart desirable properties to backbone polymers. It is versatile chemical technique that incorporates the desired features in natural fiber without affecting their inherent traits. Various workers have carried out the graft copolymerization onto different cellulosic backbone using vinyl monomers through various chemical (using wide range of initiator, oxidizer, monomers, binary vinyl monomeric mixtures) and radiation techniques [13-22].

Literature reveals that graft copolymerization of effective vinyl monomer like ethyl acrylate (EA) onto Hibiscus sabdariffa (Hs) stem fiber and its binary vinyl monomeric mixture with acrylamide (AM) and 2-vinyl pyridine (2-VP) still remains unexplored. Moreover, the Sorrel lacks therapeutic potential but its low weight, high tensile strength and rich cellulose content (73.9%) promotes its use as backbone for graft copolymerization. Therefore, it was worthwhile to screen the cumulative effect of these binary vinyl monomers on the behavioral, morphological transformations in the fiber after graft copolymerization and explore the potential of the graft copolymers as reinforcement in phenoplast (phenol-formaldehyde: P-F) polymer matrix based green composite to explore the change in mechanical strength such as flexural strength/ modulus of rupture (MOR), young’s modulus/modulus of elasticity (MOE), stress at the limit of proportionality (SP) and hardness using advanced analytical and evaluation techniques that remains unnoticed [23,24].

Experimental

Material and methods

H. sabdariffa fiber was obtained from the Department of Agronomy, Chaudhary Sarwan Kumar Himachal Krishi Vishwavidyalaya, Palampur (H.P.), India. Monomers (Merck), and Ceric ammonium nitrate, Phenol (s. d. fine-Chem, Pvt. Ltd, Mumbai, India) and formaldehyde (CDH, India) were used as received. Composites were prepared in Compression Molding Machine (SANTEC India Ltd). Libror AEG-220 (Shimadzu) electronic balance was used for weighing. Compressive/ Tensile strength, MOR, MOE and SP of the samples were tested on the Universal Testing Machine (HOUNSFIELD, H25KS). Curing and degasification were done on Compression Molding Machine (Santech India Ltd).

Characterization

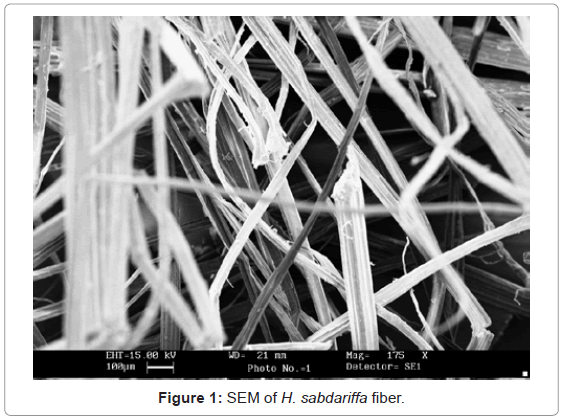

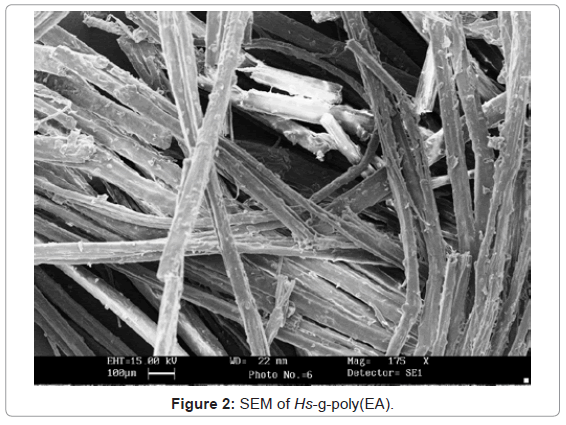

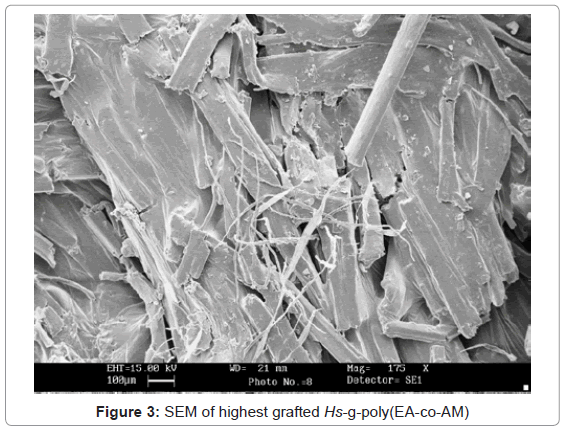

Fourier transformer infra red spectroscopy (FTIR) and Scanning electron microscopy (SEM): IR spectra of the H. sabdariffa and its graft copolymers were recorded on Perkin Elmer Fourier Transform Infrared (FTIR) spectrophotometer using anhydrous KBr (Sigma Aldrich). Scanning Electron Micrographs (SEM) of H. sabdariffa and its graft copolymers were obtained by using Electron Microscopy Machine (LEO 435-25-20), under ambient conditions.

Thermogravimetric-differential thermal analysis (TG-DTA): Thermogravimetric and differential thermal analysis were performed on thermal analyzer (LINSEIS, L-81 11). TGA of raw and grafted fiber has been studied as a function of percentage wt. loss vs. temperature.

X-ray powder diffraction (XRD): X-ray diffraction studies were performed on X-ray diffractometer (Bruker D8 Advance) under ambient conditions using Cu Kα (1.5418 Å) radiation, Ni-filter and scintillation counter as detector at 40 KV and 40 mA on rotation between 13° (2 theta) to 25° (2 theta) at 1s accumulation time and step size of 0.01 degree with 0.5° or 1.0 mm of divergent and anti-scattering slit. Each sample was homogenously mixed and mounted on PMMA holder. Corundum and quartz were used as the reference to verify and calibrate the instrument. The continuous scan between 22.68° (2 theta) and 15° (2 theta) were taken. The counter reading at the peak intensity at 22.68° (2 theta) represents the crystalline material and the peak intensity at 15° (2 theta scale) corresponds to the amorphous material in the cellulose. Crystallinity is correlated to the strength of the fiber. On grafting, the crystal lattice of the polymer is disrupted but the strength of the material may add to reinforce the structure while crystallinity index is the quantitative measure of the orientation of the crystal lattice to the fiber axis. Percentage Crystallinity (% Cr) and Crystallinity index (C. I.) were calculated by Eq. 1 and 2 [15,25-27]:

EQ (1)

EQ (1)

EQ (2)

EQ (2)

Graft copolymerization

Graft copolymerization of the monomer (EA) onto H. sabdariffa was carried-out for the optimization of different reaction conditions like reaction time, reaction temperature, monomer concentration, concentration of initiator system and pH in order to obtain the maximum graft yield. The raw fiber (0.5 g) was activated by swelling in 100 ml of distilled water for 24 h. Mixture of Ceric ammonium nitrate and conc. nitric acid was slowly added to the reaction medium under continuous stirring followed by addition of the monomer. The reaction was carried-out under ambient and pre-optimized reaction conditions. On completion of the reaction, poly(EA), poly(AM) and poly(2-VP) were removed on extraction with acetone, methanol, chloroform and water. The graft co-polymers were dried at 50°C, till a constant weight. The percent grafting (Pg) was calculated by Eq. 3 [15,25-27]:

EQ (3)

EQ (3)

where, Wf = final weight of the fiber, Wi = initial weight of the fiber.

Preparation of the polymer matrix resin

Phenol-formaldehyde resin was prepared as per the method reported earlier. Different ratios of PF were optimized with respect to their mechanical behavior so as to get better mechanical properties. P:F ratio of 0.75:1.0 was found to be the optimum ratio exhibiting better mechanical properties [25,26].

Preparation of the bio-composites

Phenol-formaldehyde matrix based bio-composites were prepared by mixing ratio of phenol: formaldehyde (0.75:1.0) and fiber to resin (12.7:87.3), respectively. The mixture was then placed in the mold of a particular dimension: 40-80 mm (length), 5×5 mm (cross section). Degasification of sample was carried-out in compression molding machine and the samples were kept for curing at 120°C for 10 minutes under 400 kg/cm2 pressure. Thus, composites were prepared by reinforcing the raw fiber and its graft copolymers. In each case, the numbers of specimen used for the determination of mechanical properties were three. Tests were conducted under ambient laboratory conditions [25,26].

Physico-chemical evaluation

Moisture absorption study: Moisture absorbance studies were carried-out at various relative humidity levels. Moisture absorbance percentage was found by placing a known weight (Wi) of dry grafted and ungrafted samples in a humidity chamber for about twelve hours and then the final weight (Wf) of the samples exposed to different relative humidities ranging from 30-90% were taken at ambient temperature. The moisture absorbance was calculated by the Eq. 4 [1-3]:

EQ (4)

EQ (4)

Acid and base resistance: Acid and base resistance studies were carried-out as shown in Eq. 5 [1-3]. A known weight (Wi) of dry grafted and ungrafted samples in fixed volume of 1N HCl and 1N NaOH was kept and the final weights (Wf) of the samples was observed after 72 hours, under ambient conditions.

EQ (5)

EQ (5)

Swelling behavior in different solvents: 250 mg of grafted and raw sample was immersed in a definite volume (100 ml) of water, methanol, n-butanol and dimethyl-formamide under ambient conditions for a period of 24 hours. Samples were removed from the solvent and excess solvent was removed with filter paper. Final weight of the sample was taken and the percentage of swelling was calculated as follows [1-3]:

EQ (6)

EQ (6)

where, W1 and W2 are the initial and final weights of samples, respectively.

Dye uptake behavior: 0.1% Gentian violet solution was prepared in distilled water. 10% NaCl solution and a few drops of acetic acid were added to this solution. Dye uptake of the raw fiber and its graft copolymers were carried-out by immersing the known weight of the sample in 100 ml of Gentian violet dye. Optical densities of the test solutions were observed using Digital Photo Colorimeter for seven consecutive hours and the concentrations of test solution were calculated as [1-3,25]:

EQ (7)

EQ (7)

where, Io, It, and Co are optical density of standard solution, optical density of test solution and concentration of standard solution, respectively.

Mechanical evaluation

Modulus of rupture (Flexural strength): MOR was determined according to ASTM D 790 standard and was calculated using the Eq. 8 [25,26]:

EQ (8)

EQ (8)

where, P = peak load, L = length of the sample, b = width of the sample and d = thickness of the sample.

Modulus of elasticity (Young’s modulus): MOE was determined according to ASTM D 790 standard and was calculated using the following equation (9) [25,26]:

EQ (9)

EQ (9)

where, P1 = load at the limit of proportionality and y = rate of bending.

Stress at the limit of proportionality: Stress at the limit of proportionality was calculated by using the equation (10) [25,26]:

EQ (10)

EQ (10)

Hardness: Hardness of the composites was tested using Rockwell Hardness tester (Balancing Instrument and Equipments Miraj Pvt. Ltd., Model-TSM) following ASTM D785 standard, using B-scale, 100 Kg as a major load and 10 Kg as a minor load with 1/16 inch indenter steel ball and was measured in HRB [25,26].

Results and Discussion

Mechanism

It is hard to justify the results merely on the basis of concentration of binary vinyl mixtures; therefore, it is important to consider the reactivity, nature and behavior of monomer species. From the literature review, it is clear that the reactivity of the acrylate monomers in reference to styrene radicals is normally higher. Since, the carboalkoxy group is highly electronegative; therefore, it causes the acrylate double bond to be positive in character. The polar character of the acrylates results in the penultimate group effects in both propagation and the termination reactions. The graft copolymerization of poly(EA) as principal monomer onto H. sabdariffa fiber was effective (Pg: 117.30). Use of ethyl acrylate as principal monomer in binary vinyl monomeric mixture with secondary monomers like acrylamide and 2-vinyl pyridine resulted in Hs-g-poly(EA-co-AM) and Hs-g-poly(EA-co-2-VP), respectively. C2, C3, and C6 hydroxyls and C-H groups were the active sites for the incorporation of polymeric chains through grafting onto cellulosics (Eq. 14 and 17). Ceric ammonium nitrate was used as a source of Ceric ion and the presence of concentrated nitric acid played an important role during graft copolymerization. In aqueous medium, ceric ion existed as [Ce-O-Ce]6+. Since, the large size [Ce-O-Ce]6+ ions were unable to form complex with the fiber so, due to the presence of nitric acid, more Ce4+ and [Ce(OH)3]3+ ions were formed. Then, these ions easily underwent complex formation with the fiber. Ceric ion formed the chelate complex with the cellulose through C-2 and C-3 hydroxyl groups of the anhydro glucose unit. Transfer of the electron from the cellulose molecule to Ce (IV) followed, leading to its reduction to Ce (III), breakage of the bonds at C-2 and C-3 that resulted in the formation of the free radical sites. Grafting of vinyl monomer onto polymeric backbone occurred as follows [15,25]:

Cell-OH + Ce4+ → Cell-O* + Ce3+ + H+ EQ (11)

M + Ce4+ → M* + Ce3+ + H+ EQ (12)

Cell-O* + M → Cell-O-M* EQ (13)

Cell-O-M* + n M + Ce4+ → Cell-O-(M)*n+1 + Ce3+ EQ (14)

(Active graft co polymeric species)

M* + nM → (M)*n+1 EQ (15)

(Active homo-polymer moiety)

(M)*n+1 + Ce4+ → (M)n+1 + Ce3+ EQ (16)

(Homo-polymer)

Cell-O-(M)*n+1 + Ce4+ → Cell-O-(M)n+1 + Ce3+ EQ (17)

(graft copolymer)

where, Cell-OH = H. sabdariffa backbone and M = monomer.

The optimized reaction conditions using EA as principal monomer onto the fiber were: monomer conc.: 2.26×10-3 mol L-1; CAN: 2.41×10-4 mol L-1; HNO3 conc.: 1.46×10-3 mol L-1; pH of the medium: 7; time: 150 minutes; temperature: 35°C that yielded Pg of 117.30 (± SD: 7.13; ± SE: 4.12). The use of ethyl acrylate as principal monomer for graft copolymerization onto H. sabdariffa fiber yielded a high Pg. It was due to high rate of propagation (Kp), low rate of termination (Kt), higher transfer rate constant (Cm) and higher reactivity of the monomer. Acrylamide has high solubility in the medium, high reactivity and high Kp that enhances the Pg (259.80) when used in binary mixture with EA. 2-VP on interaction with EA results in low graft yield (Pg: 22), because of low Cm [0.00 (25°C)], low Kp/Kt value [5.6×106 (25°C)], unfavorable reactivity ratio moreover, steric hindrance dominates its reactivity (1.30) (Table 1). However, many other factors also determine the graft yield like the type of fiber, swelling, number of active sites; the nature and amount of the solvent and temperature of polymerization strongly influence the reactivity ratios. In absence of monomer rich phase, the diluents will compete with the monomers for adsorption sites. The amount of adsorption will depend upon the total amount of surface area present and this in turn, is dependent upon the rate of stirring. Physical factors like mixing efficiency determines the melt temperature, the pressure, the rheological properties, solubility of the initiator and the monomer. Elevated temperature favors the degradation, reduces the initiator half life, modifies the rate or specificity of the reaction, and influences the solubility and rheological parameters [28-30].

| Sample | Binary mixture (×10-3mole L-1) | Mean Pg | ± SD | ± SE |

|---|---|---|---|---|

| Hs-g-poly (EA-co-2VP) |

2.26+0.76 | 22.00 | ± 3.57 | ± 2.06 |

| 2.26+1.53 | 13.00 | ± 0.90 | ± 0.52 | |

| 2.26+2.30 | 7.00 | ± 0.46 | ± 0.26 | |

| 2.26+3.06 | 2.00 | ± 0.89 | ± 0.51 | |

| 2.26+3.83 | - | - | - | |

| Hs-g-poly (EA-co-AM) |

2.26+0.23 | 165.40 | ± 4.43 | ± 2.54 |

| 2.26+0.46 | 231.70 | ± 0.88 | ± 0.50 | |

| 2.26+0.70 | 259.80 | ± 6.23 | ± 3.60 | |

| 2.26+0.93 | 110.80 | ± 4.40 | ± 2.54 | |

| 2.26+1.16 | 93.60 | ± 2.58 | ± 1.49 |

Table 1: Effect of the binary mixtures on Pg using EA as a principal monomer.

Characterization

FT-IR: IR spectrum of the H. sabdariffa showed a broad peak at 3424.0 cm-1 (–OH group) and peaks at 2924.7 cm-1, 1246.9 cm-1 and 1032.0 cm-1 were observed due to –CH2, C-C and C-O stretching, respectively. However, in case of Hs-g-poly(EA) an additional peak due to >C=O groups of the EA was witnessed at 1734.0 cm-1 whereas a peak at 3444.3 cm-1 (N-H stretch) in Hs-g-poly(EA-co-AAm) and at 1651.2 cm-1 (vinyl group) in Hs-g-poly(EA-co-2VP) confirms the incorporation of the secondary monomers in these graft copolymers.

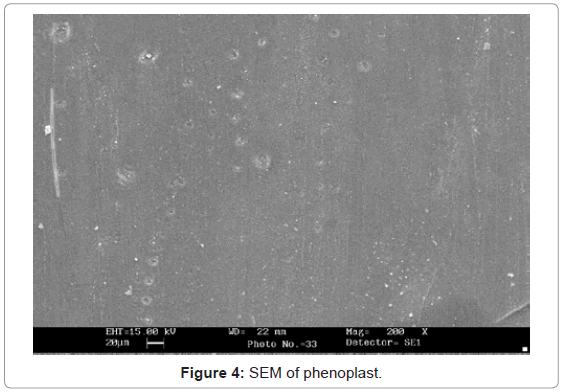

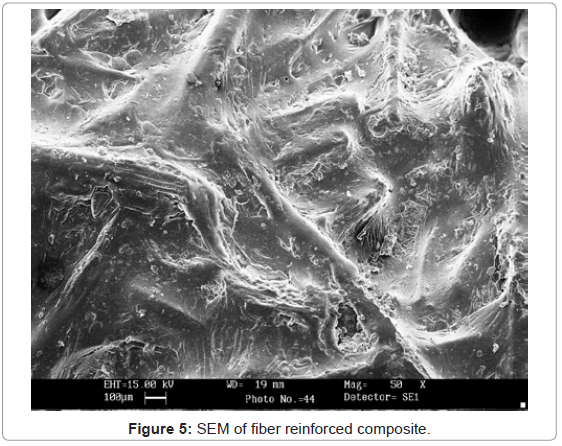

Scanning Electron Microscopy : Since, cellulose and P-F matrix had non-conducting behavior so they were gold plated to have an impact. It is quite evident from the figures 1-3, that there has been a sufficient deposition of polyvinyl monomers onto fiber. Comparison of the scanning electron micrographs of raw H. sabdariffa fiber with the graft copolymers reveals the distinction between the isolated and randomly distributed ungrafted fiber and the grafted samples that started forming the bundles in close packing, depending upon the Pg [26]. Similarly, the phenoplast when embedded with fiber and graft copolymers completely changed the surface (Figures 4,5).

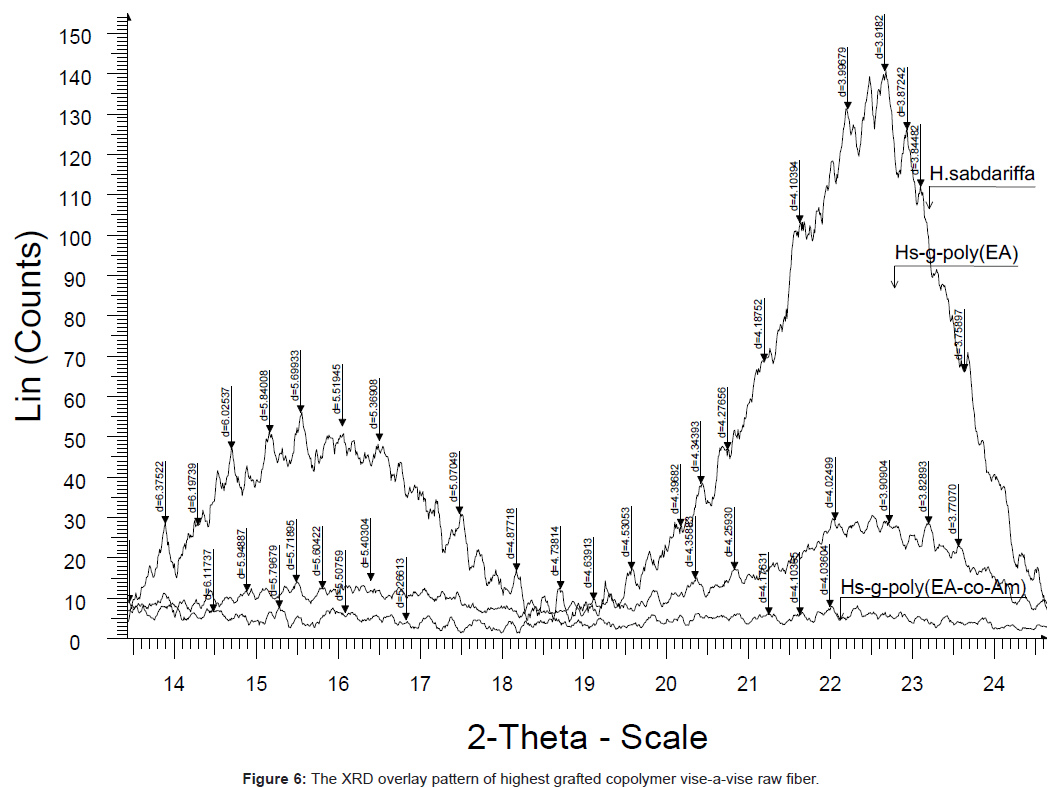

X-RD Studies: It is evident from the Figure 6 and Table 2 that the percentage crystallinity and crystallinity index were found to decrease with increase in percentage grafting of EA and its comonomer onto H. sabdariffa fiber. Since, the incorporation of monomer in the backbone impairs the natural crystallinity of the fiber; therefore, the graft copolymerization of EA onto H. sabdariffa fiber resulted in impaired crystallinity and increased the amorphous content in the fiber. Thus, with increase in percentage grafting, the percentage crystallinity and crystallinity index decreased along-with reduction in stiffness and hardness. However, the cellulose form I remained unchanged. Lower crystallinity index in case of graft copolymers stands for the poor order of crystal lattice in the fiber. The dis-orientation of the crystal lattice to the fiber axis during grafting resulted in graft copolymer with low crystallinity and crystallinity index. This clearly indicates that the cellulose crystals are better oriented in raw H. sabdariffa fiber rather than in Hs-g-poly(EA) and other graft copolymers. The PF resin gave a halo pattern while there was further increase in amorphous content with increase in fiber and grafted fiber content in the composite [15,25,27].

| Sample | Pg | 2θ Scale | %Cr | C.I. | |

|---|---|---|---|---|---|

| I15 | I22.68 | ||||

| H. sabdariffa | - | 40 | 136 | 77.20 | 0.70 |

| Hs-g-poly(EA) | 117.30 | 10 | 29 | 74.34 | 0.65 |

| Hs-g-poly(EA-co-2VP) | 22.00 | 42 | 110 | 72.36 | 0.61 |

| Hs-g-poly(EA-co-AM) | 259.80 | 05 | 06 | 54.54 | 0.16 |

where, % Cr = percentage of crystallinity, C.I.= crystallinity index

Table 2: The % Cr and C.I. of the H. sabdariffa fiber and its graft copolymers.

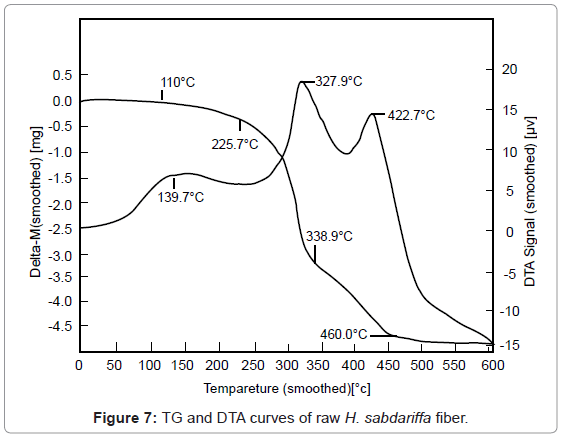

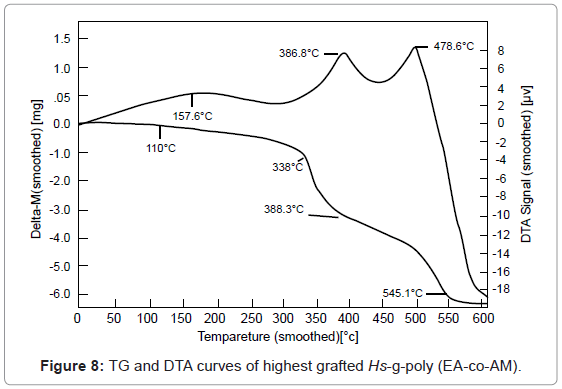

TG-DTA Studies: Cellulosic in H. sabdariffa degrades by dehydration, glycogen formation and depolymerization. In case of H. sabdariffa, two-stage thermal degradation has been found in the temperature range of 225.7-338.9°C with 54.0% weight loss and between 338.9-463.0°C with 26.00% weight loss (Table 3 and Figure 7). The former stage is attributed to the loss by dehydration, volatilization processes whereas the later stage is referred to loss by depolymerization, delignification and oxidation of the char. Hs-g-poly(EA) and Hs-g-poly(EA-co-vinyl monomer) showed two major stages of decomposition (Table 3 and Figure 8). The first stage refers to loss of moisture and decarboxylation ranging from 240.6-312.4°C and the second stage pertains to the breaking up of crystallites and covalent bonds in vinyl monomer in the range of 475.0-520.0°C. Thus, it is evident from the TGA data that grafted fibers are thermally more stable than the raw fibers. It could be due to the incorporation of poly(EA) and poly(vinyl) monomer chains on backbone polymer through strong covalent bonding or mechanically due to surface grafting, confirming the additional strength and stability to the fiber [25,31].

''''''

| Sample Hs-g-poly- |

Pg | TGA | DTA | ||

|---|---|---|---|---|---|

| IDT | FDT | % Residue | Peaks in °C(μV) | ||

| H. sabdariffa | - | 225.7 | 463.0 | 20.00 | 139.7 (6), 327.9 (18.0), 422.7 (14) |

| (EA) | 117.3 | 312.4 | 500.0 | 06.70 | 125.0 (2), 361.2 (1.2), 432.5 (29) |

| (EA-co-2VP) | 22.00 | 240.6 | 475.0 | 24.00 | 152.0 (1.6), 340.8 (3.1), 375.3 (14) |

| (EA-co-AM) Phenoplast Hs-r-PF-C |

259.8 - - |

268.0 500.0 540.0 |

520.0 600.0 680.0 |

03.30 - 10.0 |

176.4 (17.1), 340.0(21), 425.0 (22.7) 551.0 (150) 610.0 (164) |

Where, C = composite, IDT = initial decomposition temperature, FDT= final decomposition temperature

Table 3: TG-DTA of H. sabdariffa, graft copolymers and composite.

In case of DTA studies, H. sabdariffa has been found to exhibit two exothermic peaks at 327.9°C (18 μV) and 422.7°C (14 μV). Exothermic peak at 327.9°C corresponds to decomposition stage between 225.7-338.9°C while the exothermic peak at 422.7°C corresponds to second decomposition stage (338.9 - 463.0°C) in TGA (Table 3 and Figure 7). In case of graft copolymers, the first and second transition peaks revealed the dehydration, adsorption and oxidation of the semi-crystalline host and the major peak signifies the fusion and irreversible dissociation of the crystallites (Table 3 and Figure 8) [25,31].

Physico-chemico Evaluation

Moisture absorbance study: It was found that graft co-polymerization of poly(EA) and other poly(vinyl) monomer chain onto H. sabdarifa had a great impact on the moisture absorbance behavior of the fiber (Table 4). It has been observed that with increase in graft yield, there was significant decrease in the percentage of moisture absorbed. It was due to blocking of the sites vulnerable for moisture absorbance with hydrophobic poly (EA), poly(vinyl) monomer chains, thereby, transforming the fiber less sensitive to moisture. Similarly, the graft fiber reinforced composite complex showed a marked decrease in moisture absorbance due to intricate three dimension bonds in the resin that formed strong fiber matrix complex. Moreover, the monomer acted as a coupling agent to reinforce the strength in comparison to the phenoplast [1-3,25,31].

| Graft copolymer | Pg | % Chemical resistance % wt. loss after 72 hour | % Moisture absorbance at different RH after 12 hours | ||||

|---|---|---|---|---|---|---|---|

| Hs-g-poly- | 1N HCl | 1N NaOH | 30-35% | 50-55% | 60-65% | 85-90% | |

| H. sabdariffa | - | 55.0 | 43.0 | 0.5 | 0.8 | 1.8 | 2.5 |

| (EA) | 117.30 | 04.0 | - | - | - | - | 0.2 |

| (EA-co-2VP) | 22.00 | 45.0 | 38.0 | - | 0.4 | 1.2 | 2.1 |

| (EA-co-AM) Phenoplast Hs-r-PF-C |

259.80 - - |

- 04.0 01.0 |

- 02.0 - |

- - - |

- - - |

- 3.0 - |

- 5.0 3.0 |

Where, C= composite

Table 4: Chemical resistance and moisture absorbance studies of composite, graft copolymers vis-à-vis back bone.

Acid-base resistance study: It has been observed that acid- base resistance of the fiber increased with the increase in percent grafting. It could be accounted by the fact that poly(EA) and poly (vinyl) monomer chains grafted and covalently bound onto H. sabdariffa fiber had lesser reactivity for 1 N HCl and 1N NaOH as compared to the free hydroxyl groups present in the ungrafted fiber. Therefore, the resistance in the fiber for strong acid and base was found to increase by the incorporation of poly (vinyl) chains on the active sites of the backbone after graft copolymerization (Table 4). Similarly, the graft fiber reinforced composite showed a marked increase in chemical resistance due to strong fiber matrix complex formation in comparison to the Phenoplast [1-3,25,31].

Swelling behavior study: The swelling behavior studies were carried-out in different solvents like Water, MeOH, BuOH and DMF. It has been observed that H. sabdariffa fiber showed maximum swelling in Water (59%) followed by MeOH (46%), BuOH (38%) and DMF (30%). However, the swelling behavior of the graft copolymers followed the pattern: DMF > BuOH > Water > MeOH and the trend obtained had a direct correlation with the solubility parameters like solvent basicity, the molar ratio, hydrogen bond formation and the percentage grafting. The differential swelling behavior of the fibers could be justified depending upon the chemical nature and the property of the pendent groups (-CONH2, -COC2H5 and -CH=CH2) that had different interactions with the solvent. Higher swelling in DMF and BuOH in grafted copolymers could be due to better interaction with the pendent groups that increases with increase in Pg. However, a reverse trend was found in the case of raw H. sabdariffa. Since, the cellulose is semi crystalline, polar polymer and miscible with in polar solvent due to hydrogen bond formation [37] and imbibitions therefore, the raw fiber had higher swelling in water and MeOH followed by DMF and BuOH. Moreover, other factors like the fiber size, steric hindrance and temperature also influence the percentage of swelling [1-3,25,31] (Table 5).

| Sample | Pg | % Swelling | |||

|---|---|---|---|---|---|

| Water | MeOH | BuOH | DMF | ||

| H. sabdariffa | raw | 59.00 | 46.00 | 38.00 | 40.00 |

| Hs-g-poly(EA) | 117.30 | 14.00 | 10.00 | 62.00 | 78.00 |

| Hs-g-poly(EA-co-2VP) | 22.00 | 45.00 | 38.00 | 45.00 | 50.00 |

| Hs-g-poly(EA-co-AM) | 259.80 | 03.00 | 02.00 | 62.00 | 76.00 |

Table 5: Effect of solvents on swelling behavior of graft copolymers vis-à-vis backbone.

Dye-uptake behavior: The dye uptake behavior of the graft copolymers vis-à-vis raw fiber was studied for seven consecutive hours to find out the effect of grafting on dye uptake (Table 6). The graft copolymers exhibited less dye uptake as compared to the raw fiber as it was found to be a function of Pg. It was observed that dye uptake decreases with increase in Pg. Cellulose is semi crystalline polymer that easily swells due to competitive processes of adsorption through hydrogen bonding and the scission of the internal hydrogen bonds between the amorphous molecules. Presence of free reactive sites like –OH and –CH2OH in raw fiber helped in the absorption of the dye. But, these sites get occupied with poly(EA) chains and poly(EA-co-AM) and poly(EA-co-2-VP) chains in the backbone that restrain dye uptake depending upon the Pg [1-3,25,31].

| Sample | Pg | Dye concentration of the test solution at different time intervals (×10-4 mol L-1) | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 h | 2 h | 3 h | 4 h | 5 h | 6 h | 7 h | ||

| H. sabdariffa | raw | 4.96 | 4.38 | 4.08 | 4.08 | 3.79 | 3.21 | 3.21 |

| Hs-g-poly(EA) | 117.3 | 5.84 | 5.84 | 5.54 | 5.54 | 5.54 | 5.54 | 5.54 |

| H-g-ply(EA-co-4VP) | 22.00 | 5.52 | 4.96 | 4.08 | 3.05 | 3.21 | 3.21 | 3.21 |

| Hs-g-ply(EA-co-AM) | 259.8 | 5.84 | 5.84 | 5.84 | 5.84 | 5.84 | 5.84 | 5.84 |

Table 6: Dye uptake studies of the graft copolymers vis-à-vis back bone.

Mechanical assessment

Hs-r-PF composites with phenol:formaldehyde of 0.75:1.0 and fiber to matrix ratio of 12.7:87.3, depicted better mechanical behavior when subjected for the evaluation of different mechanical properties as compared to the P-F resin. Inadequate amount of fiber within the polymer matrix did not support the composite under continuous stress and strain whereas, the excess of the fiber led to debonding. Loading of the matrix beyond optimum ratio decreased the stiffness and impaired the needed fiber matrix interaction [29]. The results obtained for MOR, MOE, SP and Hardness testing (Table 7) clearly magnify the difference in mechanical strength brought about to the phenoplast after reinforcement with Sorrel and its graft copolymers. It is evident from the results, that H. sabdariffa fiber as reinforcement has improved the mechanical properties of the P-F composites. The graft copolymers reinforced bio-composites had better mechanical behavior MOR, MOE, SP and hardness as compared to raw fiber as reinforcement and phenoplast. The better mechanical behavior could be accounted due to monomer incorporated onto the fiber that acts as coupling agent, compatible fiber-matrix interaction and orientation of the fiber. However, some deviation in the results could be justified by other governing factors for overall mechanical performance like nature and amount of matrix and fiber, orientation, distribution of the fiber with respect to the matrix axis, form of reinforcement used (woven or non-woven, grafted or un-grafted), strength of the interfacial bond between the fiber and matrix, length of the fiber (continuous or discontinuous), aspect ratio that on mere imbalance may lead to debonding and cracking [25,26,29].

| Composite | Strength Test | |||

|---|---|---|---|---|

| MOR (N/mm2) | MOE (N/mm2) | SP (N/mm2) | Hardness (HRB) | |

| Phenol-formaldehyde | 43.20 | 496.12 | 38.40 | Brittle |

| H. sabdariffa-r-PF | 69.99 | 614.40 | 57.60 | 67.00 |

| Hs-g-poly(EA)-r-PF | 82.04 | 898.56 | 74.24 | 75.00 |

| Hs-g-poly(EA-co-2VP)-r-PF | 72.80 | 625.99 | 64.78 | 70.00 |

| Hs-g-poly(EA-co-AM)-r-PF | 87.96 | 789.80 | 76.56 | 82.00 |

where, -r-PF refers to reinforced Phenol-formaldehyde

Table 7: MOR, MOE, SP and Hardness studies of graft copolymers reinforced P-F composite vis-à-vis P-F resin.

Conclusions

Hs-g-poly (EA) Pg: 117.30, Hs-g-poly(EA-co-AM) Pg: 259.80 and Hs-g-poly(EA-co-2-VP) Pg: 22 obtained by using Ceric ion-nitric acid initiator system were found to have undergone tremendous physico-chemico-thermal and morphological changes. The higher graft yield obtained could be accounted by the efficient physico-chemical behavior and interaction between the monomers. With increase in grafting, dye uptake, hydrophylicity, percentage of crystallinity and crystallinity index decreased, but incorporation of poly (vinyl) chains onto the backbone that increased the physico-chemico-thermal resistance and miscibility in organic solvents. The synthesis of such novel graft copolymers is judicious, economic, fruitful means to utilize the renewable biomass for various scientific applications and the development of technology. There use as reinforcement in phenoplast matrix based composite improved the physico-chemico-thermo-mechanical competence, eased the degradation, sustained availability and alternate to glass fiber as reinforcement. These novel graft copolymer and green composites could be used in insulator, transportation, packaging and aerospace.

References

- Kaith BS, Singha AS, Sharma SK (2004) Synthesis of Graft Copolymers of Binary Vinyl Monomer Mixtures and Flax Fiber using FAS-KPS Redox System. Int J Chem Sci 2: 37-43.

- Kaith BS, Singha AS, Sharma SK (2003) Graft Copolymerization of Flax Fibers with Binary Vinyl Monomer Mixtures and Evaluation of Swelling, Moisture absorbance and Thermal Behavior of the Grafted fibers. J Polym Mater 20: 195.

- Singha AS, Kaith BS, Kumar S (2004) Evaluation of Physical and Chemical Properties of FAS -KPS induced Graft Co-polymerization of Binary Vinyl monomer mixtures onto mercerized Flax. Int J Chem Sci 2: 472.

- Kaith BS, Singha AS, Dwivedi DK, Kumar S, Kumar D, et al. (2003) Preparation of Polystyrene Matrix Based Composites using Flax-g-copolymers as Reinforcing agent and Evaluation of the Mechanical Behavior. Int J Plast Technol 7: 119-125.

- Kumar V, Bhardwaj YK, Rawat KP, Sabharwal S (2005) Radiation-induced grafting of vinylbezyltrimethylammonium chloride (VBT) onto cotton fabric and study of its anti-bacterial activities. Radiat Phys Chem 73: 175-182.

- Lee JS, Kumar RN, Rozman HD, Azemi BMN (2005) Pasting, swelling and solubility properties of UV initiated starch-graft-poly(AA). Food Chem 91: 203-211.

- Singh V, Tripathi DN, Tiwari A, Sanghi R (2006) Microwave synthesized chitosan-graft-poly(methylmethacrylate): An efficient Zn2+ ion binder. Carbohydr Polym 65: 35-41.

- Pandey PK, Srivastava A, Tripathy J, Behari K (2006) Graft co polymerization of acrylic acid onto guar gum initiated by vanadium (V)–mercaptosuccinic acid redox pair. Carbohydr Polym 65: 414-420.

- Mishra A, Bajpai M (2005) Flocculation behavior of model textile waste treated with a food grade polysaccharide. J Hazard Mater 118: 213-217.

- Akkas P, Guven O (2000) Enhancement of uranyl ion uptake by prestructuring of acrylamide-maleic acid hydrogels. J Appl Polym Sci 78: 284-289.

- El-Sherbiny IM, Abdel-Bary EM, Harding DRK (2006) Swelling characteristics and in vitro drug release study with pH- and thermally sensitive hydrogels based on modified chitosan. J Appl Polym Sci 102: 977-985.

- Qu X, Wirsen A, Albertsson AC (1999) Structural change and swelling mechanism of pH-sensitive hydrogels based on chitosan and D,L-lactic acid. J Appl Polym Sci 74: 3186-3192.

- Rudzinski WE, Dave AM, Vaishnav UH, Kumbar SG, Kulkarni AR, et al. (2002) Hydrogels as controlled release devices in agriculture. Des Mon Polym 5: 39-65.

- Huang J, Wang XL, Yu XH (2006) Solute permeation through the polyurethane-NIPAAm hydrogel membranes with various cross-linking densities. Desalination 192: 125-131.

- Chauhan A, Singh B (2011) X-Ray Powder Diffraction Studies to Accredit the Morphological Transformations in Hibiscus sabdariffa Graft-copolymers. International Journal of Polymer Analysis and Characterization 16: 319-328.

- Singha AS, Rana RK (2012) Chemically induced graft copolymerization of acrylonitrile onto lignocellulosic fibers. J Appl Polym Sci 124: 1891-1898.

- Monier M, Nawar N, Abdel-Latif DA (2010) Preparation and characterization of chelating fibers based on natural wool for removal of Hg(II), Cu(II) and Co(II) metal ions from aqueous solutions. J Hazard Mater 184: 118-125.

- Okieimen FE, Idehen KI (1987) Note Graft Copolymerization of Methyl Methacrylate on Thiolated Holocellulose. J Macromol Sci: Part A Chem 24: 1381-1384.

- Sabaa MW, Mokhtar SM (2002) Chemically induced graft copolymerization of itaconic acid onto cellulose fibers. Polym Test 21: 337-343.

- Maiti M,Jindal R,Kaith BS,Jana AK (2012) Induction of Physico-Chemical and Thermal Resistance on Saccharum spontaneum L by Grafting Under Microwave Irradiation. Int J Polym Mater 61: 1-16.

- Taghizadeh MT, Khosravy M (2003) Kinetics and mechanism of graft copolymerization of vinyl monomers (Acrylamide, Acrylic acid and Methacrylate) onto starch by potassium dichromate as redox initiator. Iran Polym J 12: 497-505.

- Zhu ZH, Ohgo K, Asakura T (2008) Preparation and characterization of regenerated Bombyx mori silk fibroin fiber with high strength. eXPRESS Polym Letters 2: 885-889.

- Thacker MS (1997) Malvaceae: A Dictionary of Indian Raw Materials & Industrial products. New Delhi: CSIR Publisher.

- Junkasem J, Menges J, Supaphol P (2006) Mechanical properties of injection-molded isotactic polypropylene/roselle fiber composites. J Appl Polym Sci 101: 3291-3300.

- Chauhan A (2009) Synthesis and evaluation of physico-chemico-mechanical properties of polymer matrix based composites using graft copolymers of Hibiscus sabdariffa as reinforcing agents. PhD Thesis, Punjab Technical University, India.

- Kaith BS, Chauhan A (2008) Synthesis, Characterization and Mechanical Evaluation of Phenol-Formaldehyde Composites. J Chem 5: S1015-S1020.

- Kaith BS, Kalia S (2007) Synthesis and Characterization of Graft co-Polymers of Flax Fiber with Binary Vinyl Monomers. International Journal of Polymer Analysis and Characterization 12: 401-412.

- Fried JR (2003) Polymer Science and Technology. (2ndedn), Prentice Hall Professional Technical Reference.

- Brandrup J, Immergut EH (1975) Polymer Handbook. (2ndedn), Wiley Interscience, John Wiley and Sons.

- Alfrey T (1964) Copolymerization. Interscience Publishers.

- Chauhan A, Kaith B (2011) Synthesis, characterization and chemical studies of Hibiscus sabdariffa-g-copolymers. Fibers and Polymers 12: 1-7.

Relevant Topics

Recommended Journals

Article Tools

Article Usage

- Total views: 14397

- [From(publication date):

September-2012 - Nov 23, 2024] - Breakdown by view type

- HTML page views : 9975

- PDF downloads : 4422